September 2023, Vol. 250, No. 9

Features

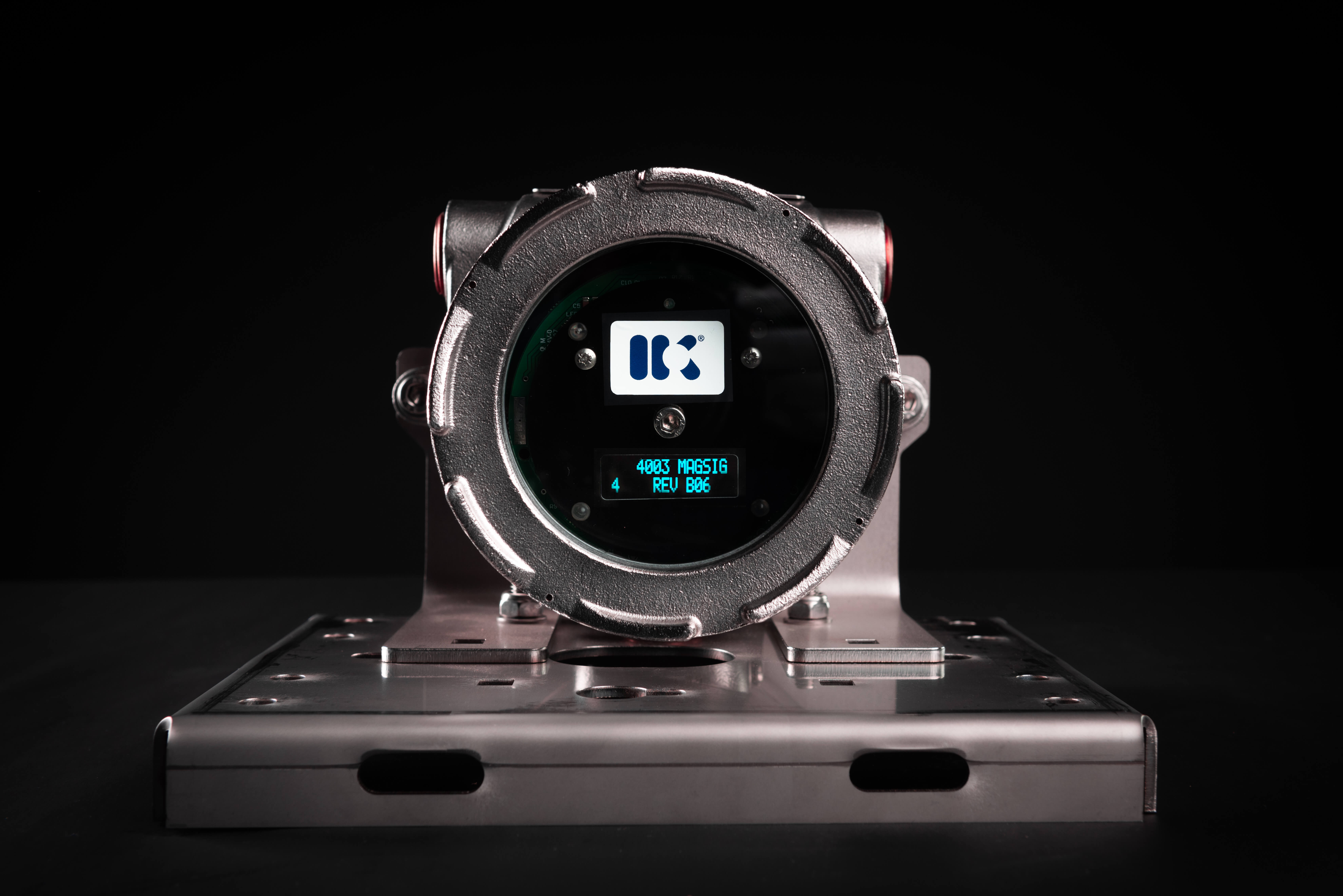

Non-Intrusive Pig Signallers: Cutting Costs, Emissions, and Environmental Risks

Sponsored ContentBy Andy Marwood, Managing Director - Online Electronics Limited

Non-intrusive pig signallers save costs, reduce emissions, and eliminate related risks to the environment and people.

By their nature, non-intrusive pig signallers do not require a nozzle hole for any type of welded fitting, whether it be a 'counter flange' or a direct fitting like a threadolet. They are simply secured to the pipeline. Simultaneously, this approach saves costs on welding, non-destructive testing, and eliminates the risk associated with potential hydrocarbon leak paths.

Intrusive pig signallers, on the other hand, have limitations in functionality as they are typically mechanical, although they can be equipped with proximity or limit switches. Moreover, human intervention is required to return the intrusive signaller's mechanical flag to the 'ready for pig' position as opposed to the 'pig passed' position. This seemingly simple task can be overlooked, especially at locations away from launcher and receiver sites, often coming to attention only when an unplanned event occurs.

The uncertainty of not knowing with certainty which pipeline features the pig has passed and has not passed can pose a serious issue. The time cost and potential risk associated with this uncertainty can be extensive, especially if it creates doubt when it comes to operating valves or determining the next best course of action.

By their nature, some pipelines span over vast onshore geographies, and 'managing' manually operated intrusive pig signallers can necessitate vehicle journeys that obviously involve time (cost) and the associated risks. This is all for the simple task of returning a pig signaller flag to the 'ready for pig' position.

Non-intrusive pig signallers, in comparison, are intelligent and offer a high degree of flexibility. They have memory capabilities, typically allowing them to recall all 'pig passed' events with time and date stamps.

They can be reset from a control room, locally via a button, or in some cases, via a Bluetooth App. With certain models, this reset includes adjusting all settings necessary, potentially enabling the identification of more than one pig passing or different pigs. Intrusive pig signallers are simply unable to perform this task.

Non-intrusive pig signallers offer various communication options. They can communicate with an operator or the control room remotely. This can provide enormous flexibility in operations, increasing assurance, reducing travel time costs, and mitigating associated risks. This allows operators to undertake other tasks. Obviously, at manned locations, non-intrusive signallers communicate via a display as well, which is critical during pig launch and pig receive activities.

Non-intrusive signaller data, when combined with other data, can provide useful information. Flow rate data can be reviewed with pig passage time stamps to determine levels of pig bypass. This assists in timing crew mobilization but perhaps more importantly may provide an indication of where the pig starts to bypass. Accurate pig passage time stamps combined with flow rate data and pipeline differential pressure data can also prove useful. It can provide an indication of when and where the pig is 'pushing' debris or perhaps passing an unknown third-party created dent.

Non-intrusive pig signallers are powered by batteries, mains, or solar energy. They can communicate via RS485 (MODBUS), volt-free contact, visual display, SMS, LoRaWan, and Bluetooth to an App. Intrusive signallers do not include these options in their standard form.

In certain, albeit rare, circumstances, intrusive pig signaller trigger assemblies can become blocked by pipeline debris such as wax and prevented from working. Equally, magnets, seals, and moving parts may need replacement from time to time. This is a hazardous task. On pig launchers and receivers, they can theoretically be isolated from hydrocarbon pressure and removed and fixed. On the pipeline side of the pig traps, this is not possible, meaning the loss of their use or operators must perform the relatively costly and risky task of removing intrusive pig signallers with special tools while the pipeline is pressurized.

Non-intrusive pig signallers are not perfect. They too can require repair. The difference is, you simply unclip them and repair them in an electronics work area. It can be very easy to simply remove one and fit a 'spare' while the original is fixed.

Non-Intrusive pig signallers offer enhanced safety, efficiency, and flexibility. Their intelligent features reduce costs, environmental risks, and operational challenges. Non-intrusive signalling - why would you not want it?

Comments