December 2023, Vol. 250, No. 12

Features

Smart Tech Takes Aim at U.S. Methane Emissions

By Mattieu St-Jean, Product Manager, ABB Measurement and Analytics

(P&GJ) — It’s hardly surprising that major gas leaks hit international headlines. Known as super-emitter events, these leaks cause plumes of methane to escape into our atmosphere — sometimes for days on end. However, these leaks are often spotted by satellites orbiting our planet before they are even known about on Earth.

According to the United Nations, 2010–2019 was the warmest decade on record. This alarming trend is attributed to greenhouse gas emissions — including carbon dioxide and methane — creating a blanket effect that traps the sun’s heat and raises temperatures.

Doing nothing means global temperatures will continue to rise, meaning we are less likely to maintain a livable climate. As such, lowering our greenhouse gas emissions is imperative in our fight against climate change.

While methane is 80 times more potent when it comes to warming than carbon dioxide, it does not remain in our atmosphere for as long. Whereas carbon dioxide remains for a century or more, methane has a life span of only about 12 years.

This means that reducing methane emissions will have a significant impact in lowering global temperatures. Indeed, according to The United Nations Environment Program, if human-caused methane emissions could be reduced by 45%, nearly 0.3˚ C of global warming would be averted by 2045.

International Rally

Having realized that reducing methane emissions is an easy win in our fight against climate change, the U.S. government — working in partnership with the European Union — launched the Global Methane Pledge initiative at the 2021 United Nations Climate Change Conference (COP26). This initiative has now brought together over 100 countries, who have pledged to collectively cut methane emissions by at least 30 per cent by 2030 from 2020 levels.

As governments rally under the Global Methane Pledge, the oil and gas industry is pivotal in implementing effective strategies. Two key initiatives — the Methane Guiding Principles (MGP) and the Oil and Gas Methane Partnership (OGMP) — are driving industry efforts.

MGP, a set of voluntary guidelines, emphasizes best practices and collaboration. Simultaneously, OGMP encourages companies to commit to reducing and transparently reporting methane emissions, providing a global framework for consistency and verifiability.

While methane is emitted from natural sources, such as wetlands, the majority comes from human activities in a variety of sectors. Industry, agriculture, land use and waste management activities all release a percentage of methane into the air; however, the energy industry is one of the biggest culprits.

According to the International Energy Agency’s Methane Tracker, the global energy industry alone released nearly 135 million tons of methane into the atmosphere in 2022. Closer to home, the Environmental Protection Agency reveals that in the US, the oil and gas sector is the largest industrial source of methane emissions, responsible for about 30% of total methane emissions.

Gas Pipelines Challenges

The U.S. has the largest network of gas pipelines in the world. Beneath our feet, there are about three million miles of pipelines threading their way across states and boundaries, to deliver natural gas supplies from production areas and storage facilities to over 73 million customers.

Every year, the interstate natural gas pipeline capacity is increased to support energy transition and increasing demand. Leaks are a common occurrence in this network of pipelines. According to the EPA, in 2019, they accounted for 1.4% of produced gas which is equivalent to $1.8 billion in lost revenue.

Pipeline methane leaks pose health and safety risks, due to flammability and contribution to smog, worsening respiratory conditions. A recent study, published in the Proceedings of the National Academy of Sciences, monitored methane emissions in the Boston area between 2012 and 2020.

The findings reveal that an average of 49,000 mtpa of methane leaked into the atmosphere. This is equivalent to the carbon dioxide emissions of around 250,000 cars operating for a year. The findings reveal that, despite small individual leaks, their cumulative impact affects costs, human safety and climate change.

There are many reasons for leaks to occur in the gas network. The most common reason is excavating accidents that result in the rupturing or puncturing of an underground pipeline. Another key reason is equipment failure or corrosion, which is to be expected when considering how long some of these pipelines have been in operation.

In fact, more than half of the natural gas pipeline network was installed in the 1950s and 1960s, following a significant rise in consumer demand for natural gas after World War II. While the pipeline network has been extended in the intervening decades, a large proportion is decades old and prone to leaks.

Future Technologies

Completely replacing aging infrastructure is, of course, unfeasible, considering the number of pipelines there are, but detecting leaks for repair is absolutely feasible. The good news is that technology has improved dramatically since the more traditional methods, enabling this detection to take place quickly, cost effectively and extremely accurately.

When it comes to detecting leaks, the challenges that arise include the inhospitable environments and remote areas where they occur. For instance, the 1,680-mile (2,702-km) Rockies Express Gas Pipeline runs from the mountains in Colorado through six states to eastern Ohio. With much of the pipeline buried underground and in inaccessible sites such as on bridges or under vegetation coverage, detecting leaks along the thousands of miles of pipeline is a challenge.

Traditional methods would entail the use of slow, outdated and insensitive equipment. Technicians would have to walk slowly along pipelines where a leak is suspected, using hand-held instruments — including organic vapor analyzers and combustible gas indicators — to test the air every few seconds.

Results would be entered manually and while leaks would be found, the overall effectiveness and sensitivity of these methods is unclear. While flying aircraft have also been used to look for visual signs of disturbance, such as dead vegetation and encroachment, this visual inspection is similarly not an accurate means of locating a methane leak.

These traditional methods are used to detect suspected or already known leaks — not the many that go unnoticed. While improved satellite technology is now able to spot super-emitter events, they don’t always spot the smaller emissions. Thankfully gas leak detection solutions on the ground have also improved significantly over the years.

Advances in sensing, analytics and mobile technology have resulted in solutions that outperform traditional methods significantly due to their sensitivity in identifying and locating methane, and at lower cost. These solutions vary, depending on use and application.

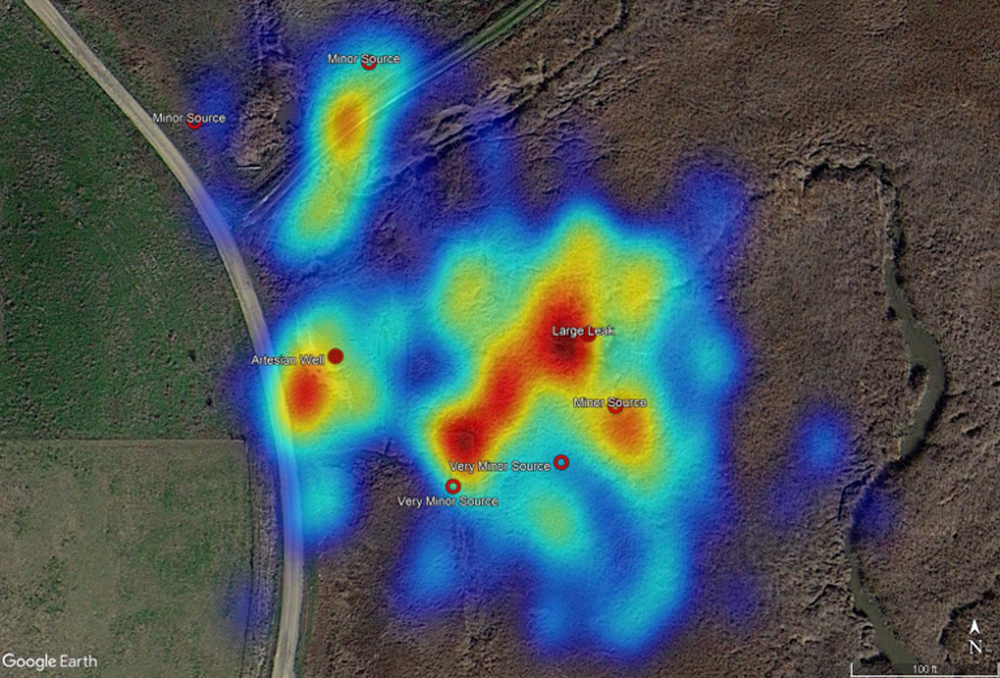

Sensors mounted on drones, passenger vehicles and aircraft can detect, map, quantify and localize leak emissions. For instance, ABB, a global manufacturer of instrumentation and analytical devices, has a complete gas leak detection portfolio consisting of a variety of advanced solutions.

For instance, its HoverGuard drone solution – with its onboard cavity-enhanced laser absorption spectroscopy, which has a sensitivity more than 1,000 times higher than traditional sensors, an ultrasonic anemometer for measuring wind speed, and a Global Navigation Satellite System (GNSS) antenna for measuring location, together with advanced data analytics – enables users to detect leaks accurately and rapidly in inaccessible locations.

Up until quite recently, operators could choose to adopt these advanced detection solutions despite the general lack of regulations requiring their use. However, with increased global focus on curbing the rise of methane emissions, regulations are set to become even more stringent around the detection and repair of gas leaks.

For instance, in 2021 the U.S. government launched the U.S. Methane Emissions Reduction Action Plan focused on cutting methane emissions, including from the oil and gas sector. This will include common-sense regulations, financial incentives, disclosure of actionable data, and public and private partnerships to identify and reduce methane emissions.

Among the regulations is the proposed Methane Leak Detection Repair Rule from the Department of Transportation’s Pipeline and Hazardous Materials Safety Administration (PHMSA). This rule will establish standards for leak detection technologies and practices and require repair of all leaks. PHMSA estimates these amendments would reduce methane emissions by 294,269 to 832,467 metric tons of CO2e each year.

Beyond Detection

However, to really tackle methane emissions takes more than just being able to detect leaks, the challenge is really being able to measure and quantify these emissions.

As such, in accordance with the Inflation Reduction Act of 2022 (IRA), in March 2023 the U.S. Department of Energy announced nearly $47 million in funding for 22 research projects to advance the development of new and innovative measurement, monitoring, and mitigation technologies to help detect, quantify, and reduce methane emissions across oil and natural gas producing regions of the United States.

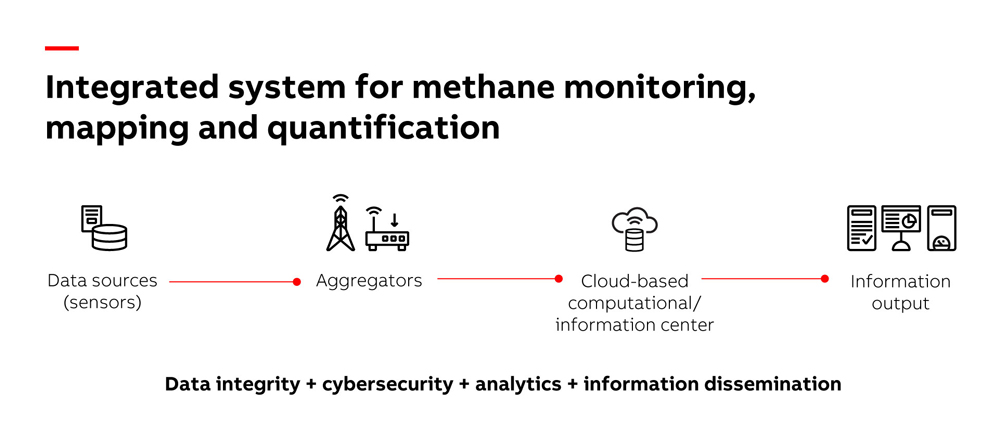

One of these research projects was awarded to ABB, which has been tasked with designing an integrated methane monitoring platform.

Today, methane emissions are recorded by a variety of users including academic researchers and technology providers, using a variety of different methods and the data is then stored in a variety of locations where it is analyzed in its own silo. These differing formats, technologies and methodologies have made it difficult to compare and analyze data on a like-for-like basis.

In this project, ABB will build a single repository that will aggregate, analyze, and visualize methane data from all these multiple sources. With the data all in one comprehensive system, it will then be analyzed using advanced Big Data analytics with the results clearly visualized providing a complete picture of where and who the emitters are on geospatial maps.

The aim is that providing rapid identification, localization, and characterization of all methane emissions from super-emitters and intermittent sources all the way through to the smaller but persistent emission sources, will enable stakeholders, including government policymakers, to identify emissions rapidly and accessibly so as to be able do something about them.

For instance, this data can be used for the development of effective policy solutions. More so, it will provide actionable information to oil and gas companies to enable them to take critical action in reducing their methane emissions.

Methane emissions are a waste of energy, money and present significant risks to life on our planet, as well as the health of our plant itself. The development of advanced gas leak detection technology, along with more stringent legislation, will help identify emissions to ensure that in the future our natural gas infrastructure is resilient, efficient and leak tight.

Comments