October 2009 Vol. 236 No. 10

Features

Pipeline Hydro Test Pressure Determination

Hydrostatic testing has long been used to determine and verify pipeline integrity. Several types of information can be obtained through this verification process.

However, it is essential to identify the limits of the test process and obtainable results. There are several types of flaws that can be detected by hydrostatic testing, such as:

- Existing flaws in the material,

- Stress Corrosion Cracking (SCC) and actual mechanical properties of the pipe,

- Active corrosion cells, and

- Localized hard spots that may cause failure in the presence of hydrogen.

There are some other flaws that cannot be detected by hydrostatic testing. For example, the sub-critical material flaws cannot be detected by hydro testing, but the test has profound impact on the post test behavior of these flaws.

Given that the test will play a significant role in the nondestructive evaluation of pipeline, it is important to determine the correct test pressure and then utilize that test pressure judiciously, to get the desired results.

When a pipeline is designed to operate at a certain maximum operating pressure (MOP), it must be tested to ensure that it is structurally sound and can withstand the internal pressure before being put into service. Generally, gas pipelines are hydrotested by filling the test section of pipe with water and pumping the pressure up to a value that is higher than maximum allowable operating pressure (MAOP) and holding the pressure for a period of four to eight hours.

ASME B 31.8 specifies the test pressure factors for pipelines operating at hoop stress of ? 30% of SMYS. This code also limits the maximum hoop stress permitted during tests for various class locations if the test medium is air or gas. There are different factors associated with different pipeline class and division locations. For example, the hydrotest pressure for a class 3 or 4 location is 1.4 times the MOP. The magnitude of test pressure for class 1 division 1 gas pipeline transportation is usually limited to 125% of the design pressure, if the design pressure is known. The allowed stress in the pipe material is limited to 72% of SMYS. In some cases it is extended to 80% of SMYS. The position of Pipeline and Hazardous Material Safety Administration (PHMSA) is similar. Thus, a pipeline designed to operate continuously at 1,000 psig will be hydrostatically tested to a minimum pressure of 1,250 psig.

Based on the above information, let us consider API 5L X70 pipeline of 32-inch NPS, that has a 0.500-inch wall thickness. Using a temperature de-rating factor of 1.00, we calculate the MOP of this pipeline from following:

P= {2x t x SMYS x1x factor (class1) x 1} / D (ASME B 31.8 Section, 841.11)

Substituting the values:

P= 2x 0.5 x 70,000 x1 x0.72 x1/32 = 1,575 psig

For the same pipeline, if designed to a factor of 0.8, the MOP will be computed to be 1750 psig.

- If the fittings were the limiting factors of the test pressure, then the following situation would arise.

- If the fittings used in the system are of ANSI 600 then the maximum test pressure will be (1.25 x 1,440) 1,800 psig. This test pressure will support the requirements of both factor 0.72 and 0.8.

- If, however, ANSI 900 fittings were chosen for the same pipeline system, the test pressure (1.25 x 2,220) 2,775 psig would test the pipeline but would not test the fittings to their full potential.

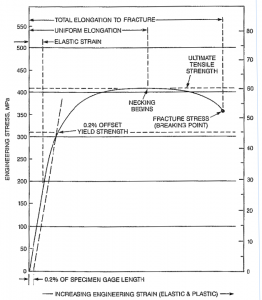

Let us first discuss the design factor of 0.72 (class1). In this case the test would result in the hoop reaching to 72% of the SMYS of the pipe material. Testing at 125% of MOP will result in the stress in the pipe reaching a value of 1.25 x 0.72 = 0.90 or 90% of SMYS. Thus, by hydrotesting the pipe at 1.25 times the operating pressure, we are stressing the pipe material to 90% of its yield strength that is 50,400 psi (factor 0.72).

However, if we use a design factor of 0.8 – as is now often used – testing at 125% of MOP will result in the stress in the pipe to 1.25 x 0.8 =1. The stress would reach 100% of the yield strength (SMYS). So, at the test pressure of 1800 psig the stress will be 56,000 psi (for factor 0.8). This will be acceptable in case of class 600 fittings. But, if class 900 fittings were taken into account, the maximum test pressure would be (1.25 x 2,220) 2,775 psig and the resulting stress would be 88,800 psi which will be very near the maximum yield stress (90,000 psi) of API 5L X 70 PSL-2 material.

Test Pressure And Materials SMYS

Though codes and regulatory directives are specific about setting test pressure to below 72% or in some cases up to 80% of the SMYS of the material, there is a strong argument on testing a constructed pipeline to “above 100% of SMYS,” and as high as 120% of SMYS is also mentioned. Such views are often driven by the desire to reduce the number of hydrotest sections, which translates in reduction in cost of construction. In this context, it is often noted that there is some confusion even among experienced engineers on the use of term SMYS and MOP/MAOP in reference to the hydrotest pressure.

It may be pointed out that the stress in material (test pressure) is limited by the SMYS. This is the law of physics, and is not to be broken for monetary gains at the peril of pipeline failure either immediate or in the future.

In this regard, section 32 of directive No. 66 of the Alberta Energy and Utilities Board in 2005 is of importance. The guidance is specific about the situation. It directs that if the test pressure causes hoop stress in the material exceeding 100% of the material SMYS, then the calculation and the entire hydro test procedure needs to be submitted to the board for review and approval.

Stress Relieving And Strength

Often there is argument presented that higher test pressures exceeding 100% of the SMYS will increase the “strength” of the material and will “stress relieve” the material. Both arguments have no technical basis to the point they are made. We will briefly discuss both these arguments here:

1. Higher test pressure will “increase the strength.” As the material is stressed beyond its yield point, the material is in plastic deformation stage, which is a ductile stage, and hence it is in the constant process of losing its ability to withstand any further stress. So, it is not increasing in strength but progressively losing its strength.

2. The second argument of “stress reliving” is linked with the “increase the strength” argument. The stress relief of material is carried out to reduce the locked-in stresses. The process reorients the grains disturbed often by cold working or welding. The stress relief process effectively reduces the yield strength. Thus, it does not “strengthen” the material. Note: It may be pointed out that a limited relaxation of stresses does occur by hydro testing, but the test pressure should be less than the material’s yield point.

Another point to note here is that there is a stage in the stressing of the material where strain hardening occurs and the material certainly gains some (relative) hardness, and thereby, strength. This happens as necking begins but, at that point, unit area stress is so low that the strength of the material is lost and it remains of no practical use, especially in context with the pipe material we are discussing.

Returning to the subject of pressure testing and its objectives. One of the key objectives of the testing is to find the possible flaws in the constructed pipeline. The test develops a certain amount of stress for a given time to allow these possible flaws to open out as leakages. In the following section we shall discuss the relation of these flaws to the test pressure and duration.

Critical Flaw Size

The maximum test pressure should be so designed that it provides a sufficient gap between itself and the operating pressure. In other worlds, the maximum test pressure should be > MOP.

This also presupposes that after the test the surviving flaws in the pipeline shall not grow when the line is placed in service at the maintained operating pressure. For setting the maximum test pressure, it is important to know the effect of pressure on defect growth during the testing on the one hand and on the other flaws whose growth will be affected by pressure over the time.

The defects that would not fail during a one-time, high test pressure are often referred as sub-critical defects. However these sub-critical defects would fail at lower pressure if held for longer time. But the size of discontinuity that would be in the sub-critical group would fail-independent of time-at about 105% of the “hold” pressure. This implies that maximum test pressure would have to be set at 5-10% above the maximum operating pressure (MOP) in order to find such defects during the test and also to avoid growth of sub-critical discontinuities after the hydro test pressure is released and during the operation life of pipeline. This is should be the main objective of the hydro test.

If test pressure reaching 100% (design factor of 0.80) of the SMYS is considered, then one must also consider some important pre conditions attached to the procurement of the steel and pipe. Especially important to consider is the level of flaw size that was accepted in the plate/coil used to manufacture the pipe. The test pressure of such magnitude would require that the acceptable defect size be re-assessed. This is because all else being equal, a higher design factor, resulting in a thinner wall, will lead to a reduction in the critical dimensions of both surface and through-wall defects.

Where such conditions are likely it may be prudent to reconsider the level of accepted flaws in the material. The current recommendations in API 5L 44th edition for acceptance level B2 as per ISO 12094 (for SAW pipes) may not be acceptable because it has limited coverage of body and edges and the acceptance criteria is far too liberal, in terms of acceptable size and area of flaws. More stringent criteria must be specified more in line with EN 10160 where level S2 for body and level E2 for edges may be more appropriate to meet the demands of the higher test pressures.

Sub-critical surface flaw sizes at design factors of 0.80 and 0.72 are susceptible to growth at low stress and are time dependent. These flaws are also dependent on the acceptable limits of impact absorbing energy of the material and weld (not part of the discussion in this article).

This increase in depth-to-thickness (d/t) ratio in effect reduces the ligament of the adjoining defects that reduce the required stress to propagate the discontinuity. Critical through-wall flaw lengths are also factors to be assessed. While there is a modest reduction in critical flaw length, it still indicates very acceptable flaw tolerance for any practical depth and the reduction will have negligible influence in the context of integrity management. Note that flaws deeper than about 70% of wall thickness will fail as stable leaks in both cases. This statement implies that mere radiography of the pipe welds (both field and mill welds) may not suffice. Automatic ultrasonic testing (AUT) of the welds will be better suited to properly determine the size of the planer defects in the welds. Similarly the use of AUT for assessing the flaws in the pipe body will be more stringent than usual.

Pressure Reversal

The phenomenon of pressure reversal occurs when a defect survives a higher hydrostatic test pressure but fails at a lower pressure in a subsequent repressurization. One of the several factors that work to bring on this phenomenon is the creep-like growth of sub-critical discontinuities over time and at lower pressure. The reduction in the wall thickness, caused by corrosion, external damages, is also responsible for a reduction in puncture resistance in the pipe. The reduction in the wall thickness, in effect reduces the discontinuity depth to the material thickness.

This increase in d/t ratio reduces the ligament between the adjoining defects. This effectively reduces the stress required to propagate the discontinuity. The other factor affecting the pressure reversal is the damage to the Crack Tip Opening (CTO). The CTO is subject to some compressive force leading the crack tip to force-close during the initial test. On subsequent pressurization to significantly lower pressure this “force-close” tip starts to open-up and facilitates the growth of the crack. Hence, if such a pressure cycle is part of the design, then the point of pressure reversal should be considered.

Puncture Resistance

- It may also be noted that there is a modest reduction in puncture resistance with both increasing SMYS and increasing design factor. Note that the maximum design factor is, in some instances, constrained by practical limits on D/t.

- In any event, it should be noted that only a small proportion of large excavators are capable of generating a puncture force exceeding 300 kN and that the reductions in puncture resistance noted would have to be assessed for the integrated approaches to the management of mechanical damage threats.

Author

Ramesh Singh is Senior Principal Engineer (Materials, Welding and Corrosion) for Gulf Interstate Engineering, 16010 Barkers Point Lane, Houston, Texas 77079-9000, 713-850-3687, Fax: 713-850-3554, E-mail: rsingh@gie.com.

Bibliography

49 CFR Part 192 Part-V, “Pipeline Safety: Standards for increasing the Maximum Allowable Operating Pressure for Gas Transmission Pipelines,” Final Rule issued Dec. 17, 2008.

Anonymous, 1996. National Energy Board Report on the Public Inquiry Concerning Stress Corrosion Cracking on Canadian Oil and Gas Pipelines.

Anonymous, 2005. 6th Report of the European Gas Pipeline Incident Data Group,” EGIG 05R.0002. See EGIG website: http://www.EGIG.nl.

ASME B 31.8 Gas transmission and Distribution Piping system.

Chen, Q., Fuglem, M., Stephens, M., and Zhou, J., 2001. “Reliability-Based Design for Mechanical Damage,” 13th Biennial PRCI/EPRG Joint Technical Meeting, Paper 1.

Driver, R.G. and Zimmerman, T.J.E., 1998. “A Limit States Approach to the Design of Pipelines for Mechanical Damage,” Proc. 17th OMAE Conference, Paper OMAE98-1017.

Duffy, A.R., McClure, G.M., Maxey, W.A. and Atterbury, T.J., 1968. “Feasibility of Basing Natural Gas Pipeline Operating Pressure on Hydrostatic Test Pressure,” PRC/AGA NG-18 Report L30050.

Eiber, R.J., Hopkins, P., McLamb, M., and Abes, J., 2004. “Operation of New Design and/or Conversion of Existing Gas Pipelines to 80% SMYS Operating Stress,” GRI Report GRI-04-0152.

EN 10160 – 1999, Ultrasonic testing of steel flat product of thickness equal or greater than 6 mm (reflection method).

ISO 12094 – 1994 Welded steel tubes for pressure purposes-Ultrasonic testing for the detection of laminar imperfections in strip/plate used in the manufacture of welded tubes.

Rothwell, Brian, Staff Engineer, TransCanada PipeLines, “History and Operating experience of design factors above 0.72 in Canadian gas transmission pipelines.”

Texas Eastern, Technological Review of Hydrostatic Testing. Dec. 04, 1985.

Comments