July 2014, Vol. 241, No. 7

Features

Safety Deeply Embedded In Pipeline, Hazardous Transport Oversight

(Editor’s Note: This article is part of a continuing P&GJ series detailing how increasing federal safety mandates affect the oil and gas industry.)

In 2010, two tragic events – a million-gallon crude oil spill near Marshall,

MI and a natural gas explosion in a San Bruno, CA neighborhood – occurred within two weeks of each other, focusing the nation’s attention on pipeline safety.

In both instances, National Transportation Safety Board (NTSB) investigators cited weak regulations and inadequate oversight by the federal Department of Transportation’s Pipeline and Hazardous Materials Safety Administration (PHMSA) as contributing factors.

PHMSA outlines its response in a 2012-16 strategic plan, and through related documents, congressional testimony and material posted on its website. The agency’s Office of Hazardous Materials Safety (OHMS) further explains its goals in Strategic Plan 2013-2016: The Road Ahead. Many of the strategies reflect mandates contained in the Moving Ahead for Progress in the 21st Century Act (MAP-21).

Priorities include placing a greater emphasis on incident reporting and early intervention, adherence to the globally harmonized system of classification and labeling of chemicals (GHS), and embracing sound risk management principles to help identify, assess, and manage incidents and monitor trends.

Measuring Effects

PHMSA administers nationwide safety programs designed to protect the public and the environment from risks in the commercial transportation of hazardous materials by air, rail, vessel, highway and pipeline. Most of the nation’s pipeline infrastructure is owned by the private sector or local utilities; federal safety regulations are aimed at ensuring the infrastructure is sound.

Hazardous materials transport is a complex business with many stakeholders. Consequently, the PHMSA faces a number of challenges, including the broad scope of its mission and the need to demonstrate its effectiveness to elected officials, watchdog organizations and the general public. In its 2013 budget overview, PHMSA said its work “often goes unnoticed” because it successfully prevents and contains incidents.

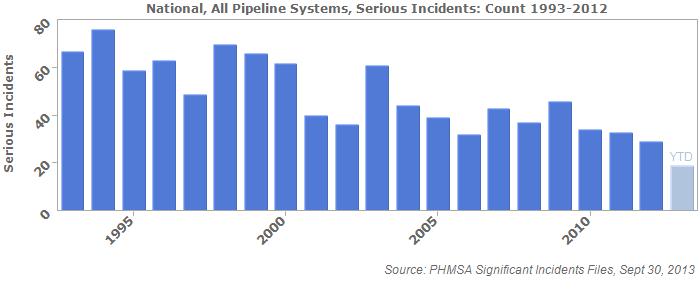

Federal data show the number of pipeline or hazardous materials-related incidents resulting in death or major injury has declined over the past 25 years. Hazardous materials transportation incidents resulting in death or major injury has been reduced by 4% every three years, and pipeline incidents with death or major injury has dropped by about 10% every three years. In addition, since 2002, the risk of hazardous liquid pipeline spills with environmental consequences has declined by an average of 5% a year.

Hazardous materials transportation (all modes, including pipelines) accounts for an average of 28 deaths a year, or about one death out of every 11 million people in the U.S. Accordingly, PHMSA notes in its strategic plan that accidents in hazardous materials transportation are low-probability risks. However, it acknowledges “these accidents can be very high-consequence failures when they do occur, because they can involve lethal forces or toxic materials that can strike almost anywhere. Annual accident data do not necessarily reveal all the threats. And some groups – particularly workers – face higher risks than others.”

Long-Term Vision

PHMSA has identified a series of objectives to reach by 2016. These include reducing the number of:

• pipeline incidents involving death or major injury to between 26-37 per year

• hazardous materials incidents involving death or major injury to 21-32 per year

• hazardous liquid pipeline spills with environmental consequences to between 65-81 per year

• hazardous materials incidents with environmental damage to between 44-64 per year

Recent PHMSA Actions

On Sept. 30, just before the federal government shutdown, the agency announced that more than $46 million in Pipeline Safety Base grants will go to 46 states, the District of Columbia and Puerto Rico. It also recently awarded eight universities nearly $800,000 to study ways to improve pipeline safety.

The base grants are allocated on the basis of jurisdiction expenses and annual performance scores. They cover up to 80% of operating costs for pipeline regulators who agree to inspect intrastate pipelines on the agency’s behalf. Participating states and territories account for more than 300 inspectors who are responsible for about 90% of the country’s intrastate natural gas and hazardous liquid pipelines.

“These funds enable us to triple the number of inspectors we have out in the field enforcing regulations,” said PHMSA Administrator Cynthia Quarterman. “A strong local presence is vital to effectively monitor pipelines and help protect the public from pipeline incidents.”

Risk Management

The agency’s Office of Hazardous Materials Safety is developing a risk management framework to ensure the entire agency operates as a risk-based organization. The framework is supplemented by specific methods, tools and guidance documents.

“We will improve our data collection and analysis capabilities and provide data?driven processes within this framework to drive agency decisions to address the highest transportation risks and maximize our limited resources toward ensuring the safe and efficient transportation of hazmat,” the strategic plan said.

Incident Management Reporting

PHMSA emphasizes the value of a workplace culture that encourages incident management reporting and early intervention.

Section 171.15 of Hazardous Materials Regulations (49 CFR, Parts 171-180) requires notice of certain hazardous materials incidents “as soon as practical but no later than 12 hours after the occurrence” by telephone to the National Response Center (NRC) or online. For pipeline incidents, the PHMSA “expects” telephonic reports to the NRC to occur within two hours of the incident and a written report to be filed within 30 days, preferably by electronic submission.

Under 49 CFR, Section, 191.5, (Part 191 addresses transportation of natural and other gas by pipeline) immediate notice of certain gas pipeline incidents is required “at the earliest practicable moment following discovery.”

In 2012, the NRC received 32,551 incident reports. Of those, 1,043 were related to pipelines, which is one of 14 categories by incident type.

PHMSA tracks and sorts data on the frequency of failures, incidents and accidents, causes and consequences by categories, such as date, location, type, cause and result. It uses incident data to assess safety trends and guide the development of new initiatives. In a recent development, analysts and others who use hazardous materials data now have the ability to drill down to view specific computer-generated incident reports representative of DOT form 5800.1, the standard incident reporting template.

Enforcement

The federal hazardous material enforcement program refers matters which are believed to compromise safety to the PHMSA’s Office of the Chief Counsel. Sanctions may include notices of probable violations and corrective action and compliance orders. Federal law authorizes the chief counsel to assess a civil penalty or refer matters for criminal prosecution.

The Pipeline Enforcement Program uses a variety of mechanisms to encourage operator compliance and safe operation. Title 49, Part 190, Subpart B “Enforcement” in the Code of Federal Regulations includes corrective action orders, notices of probable violations, warning letters, notices of amendment and letters of concern which may lead to an enforcement process and criminal penalties.

Improvement Plan

In August 2013, the agency’s Office of Hazardous Materials Safety released the Hazardous Materials Transportation Incidents Data Assessment and Improvement Plan, a comprehensive report containing a series of recommendations in accordance with the MAP-21 Act. The act requires DOT to conduct an assessment and develop an action plan and timeline to improve the collection, analysis, reporting and use of data related to accidents and incidents involving hazardous materials.

Among key findings in the report:

1. There are limitations in the manner in which some data is collected. Related recommendations:

• establish clear definitions for terminology used on the reporting form

• create a “smart form” that tailors information collection based on the mode of transportation and type of incident reported

• collect factual and verifiable failure information and reduce or eliminate collection of information that can be subjective

• require report filers to certify the information submitted is accurate and complete

2. There are reporting biases, under-reporting and partially completed forms that affect the accuracy and completeness of the data. While PHMSA verification and validation efforts focused on incidents resulting in fatalities and injuries were found to be “very accurate,” audits are not performed on incidents with low consequences. In addition, 40% of report submissions are received via paper, which requires more resources to verify accuracy and completeness. Related recommendations:

• collect a random sample of less consequential incidents to better understand the accuracy of the data and determine when improvements are needed

• cross-reference data from other DOT sources, such as the National Highway Transportation Safety Administration’s Fatality Analysis Reporting System and Federal Railroad Administration’s Rail Equipment Accident/Incident Reports

• verify incident information from others in the supply chain, such as shippers

• expand procedures for correcting errors

• require electronic reporting to reduce errors and focus resources on verifying data

• improve compliance with reporting requirements and understanding of the incident report form

3. While authorities agree certain low-risk materials could be exempt from reporting requirements, additional study is needed to determine if more widespread changes in reporting thresholds are necessary. Additionally, report filers may need more time to collect accurate information from significant and complex incidents. Related recommendations:

• change reporting requirements to focus data collection, processing and analyses on incidents that have the greatest risk to safety and the environment

• allow filers reporting incidents that resulted in serious consequences to request an extension provided initial information is reported

• continue to use existing authorities and regulations to conduct special studies and incident investigations in order to verify or obtain additional information from others in the supply chain

Finally, recommendations to improve access and use of incident data include:

• establish a “one-stop-shop” for hazardous materials incident data, including definitions and metadata

• expand search capabilities and assign keywords to incident reports

• redesign/replace the online reporting tool as part of information technology modernization efforts. (This depends on appropriation of federal funds for IT modernization in 2014 and beyond.)

Author: Karen O’Hara has worked in the field of occupational health and safety for more than 20 years and serves as Communications Specialist at UL Workplace Health and Safety.

Update On 2010 Pipeline Disasters

The National Transportation Safety Board (NTSB) published the Enbridge Incorporated Hazardous Liquid Pipeline Rupture and Release in 2012. The report described how a July 25, 2010 crude oil leak went undetected by a control center for more than 17 hours, allowing more than 1.1 million gallons of oil to saturate wetlands and flow via a tributary into the Kalamazoo River, near Marshall, MI.

The Michigan Department of Community Health identified 320 residents and 11 worksite employees who experienced headaches, nausea, respiratory ailments and other health problems associated with crude oil exposure. More than 180,000 gallons of “submerged oil” still remain at the bottom of the river, and ongoing recovery costs are expected to exceed $1 billion.

Investigators identified corrosion fatigue cracks as the probable cause. The NTSB cited operator failures, including “inadequate training of control center personnel.”

The board also held the PHMSA partly responsible, saying, “Contributing to the accident was the (PHMSA’s) weak regulation for assessing and repairing crack indications, as well as PHMSA’s ineffective oversight of pipeline integrity management programs, control center procedures and public awareness.”

Not long afterward, Sept. 9, a 30-inch segment of an intrastate natural gas transmission pipeline, owned and operated by the Pacific Gas and Electric Company (PG&E), ruptured in a residential area in San Bruno, CA. The gas ignited, resulting in a fire that destroyed 38 homes and damaged 70. Eight people were killed and many more were injured.

In its report, the NTSB cited the probable cause as “inadequate quality assurance and quality control” by PG&E, which allowed the installation of a substandard and poorly welded pipe section and an “inadequate pipeline integrity management program, which failed to detect and repair or remove the defective pipe section.”

In addition, according to the NTSB, California Public Utilities Commission (CPUC) and U.S. Department of Transportation exemptions of existing pipelines from a regulatory requirement for pressure testing were contributing factors. The investigation also determined that the CPUC failed to detect inadequacies in PG&E’s integrity management program and in the PHMSA’s integrity management inspection protocols and data collection. Without effective and meaningful metrics in performance-based pipeline safety management programs, neither PG&E nor the CPUC were able to effectively evaluate or assess the pipeline system, investigators concluded.

San Bruno city officials report the PHMSA is challenging the CPUC to demonstrate compliance and prove its ability to ensure pipeline safety. In a letter to San Bruno Mayor Jim Ruane, the PHMSA said it takes San Bruno’s concerns “very seriously” and announced plans to conduct an audit of the CPUC.

Comments