Enbridge, Baker Hughes Partner on Enhanced Inspection for Pipeline Safety

Enbridge and G.E. company Baker Hughes launched testing of new, ultrasonic phased array pipeline inspection tool sensors designed to enhance accuracy and identification of crack features and to deliver greater detail on the condition of a pipeline.

The testing phase follows 14 months of development of a multi-year research and development project to advance pipeline inspection tool sensor technology and, ultimately, pipeline safety.

“Proactive investments in innovation and technology like this are intended to add another layer of safety to our pipeline networks and ultimately, benefit the industry as whole,” said Walter Kresic, Enbridge’s Vice President Pipeline Integrity.

Similar to MRI or ultrasound technology used in the medical industry, pipeline inspection tool sensors provide the ability to detect and accurately characterize anomalies that could affect the health of a pipeline. The next generation of inspection tools will provide more accuracy and higher resolution, enabling better maintenance and an overall improvement on the assurance of pipeline safety.

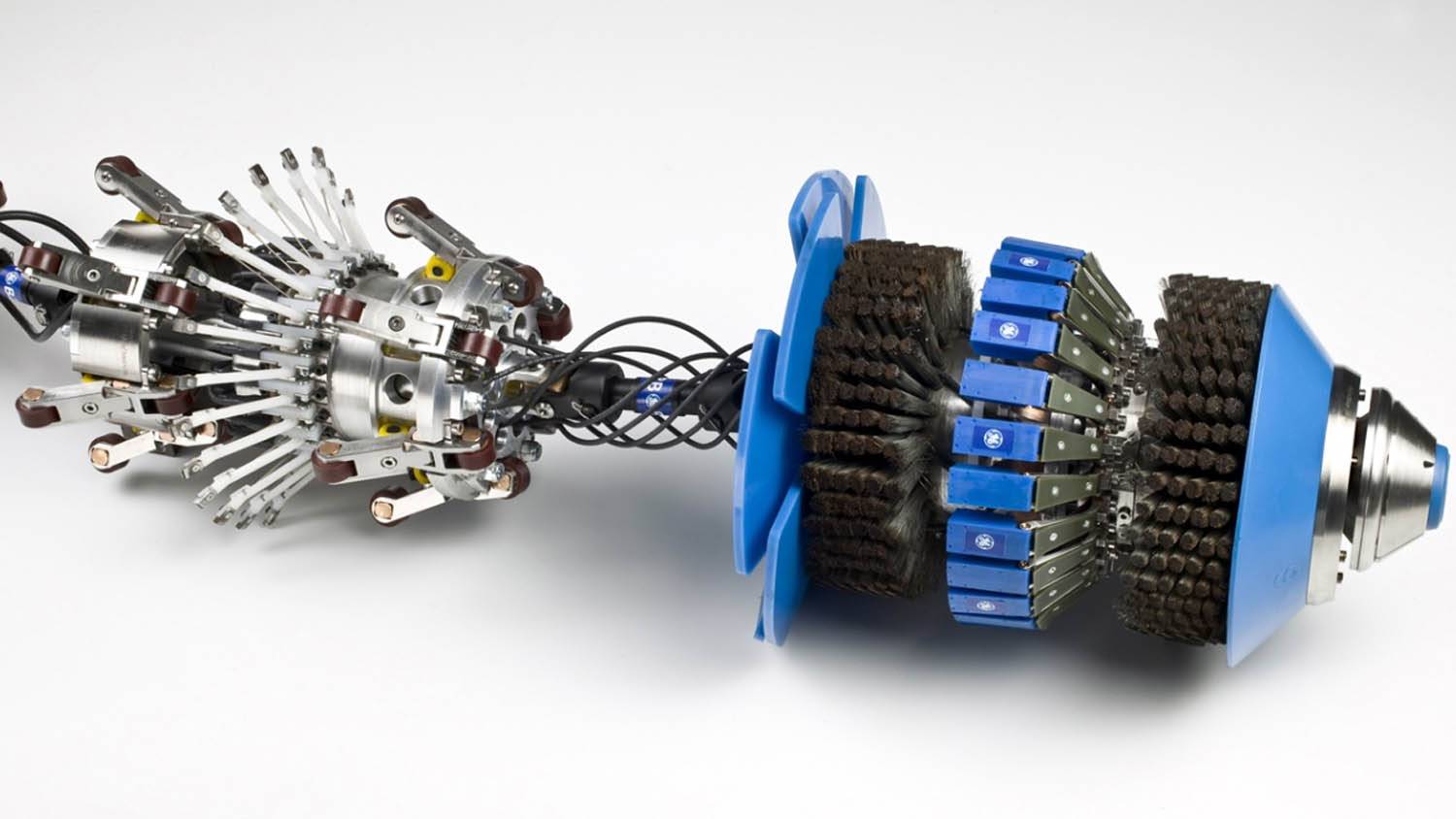

The next generation of phased array sensor technology will represent a significant step change in pipeline inline inspection, enabling a more comprehensive assessment of the threats to pipeline integrity, the companies said. The sensors are mounted on a robotic inspection device, or smart pig, which travels along the inside of a pipeline, measuring the condition of the pipe wall as it goes.

Related News

Related News

- Keystone Oil Pipeline Resumes Operations After Temporary Shutdown

- Biden Administration Buys Oil for Emergency Reserve Above Target Price

- Freeport LNG Plant Runs Near Zero Consumption for Fifth Day

- Enbridge to Invest $500 Million in Pipeline Assets, Including Expansion of 850-Mile Gray Oak Pipeline

- Williams Delays Louisiana Pipeline Project Amid Dispute with Competitor Energy Transfer

- Evacuation Technologies to Reduce Methane Releases During Pigging

- Editor’s Notebook: Nord Stream’s $20 Billion Question

- Enbridge Receives Approval to Begin Service on Louisiana Venice Gas Pipeline Project

- Mexico Seizes Air Liquide's Hydrogen Plant at Pemex Refinery

- Russian LNG Unfazed By U.S. Sanctions

Comments