BHGE AM '18: Design Challenges of Novatek's Yamal LNG, Arctic LNG 2

FLORENCE—In a keynote speech on Day 2 of the 2018 BHGE Annual Meeting (BHGE AM), Mark Gyetyay, CFO and deputy chairman of the management board of Novatek, discussed the Yamal LNG and Arctic LNG 2 projects in Russia.

The execution of the Yamal LNG project, which Gyetyay called “one of the most difficult projects in the world,” required innovative solutions. More than 650 companies were involved in its execution. The project was started up Dec. 8.

Yamal LNG required specially built equipment due to the harsh arctic conditions. A total of 38,000 pylons were constructed for the equipment to rest on, to prevent damage from permafrost. Each pylon was built with a heat exchanger inside.

Contractors also built special vehicles to transport equipment to the site. The vehicles were modular built, with some weighing as much as 5,000 tons. Also, more than 5,000 local contractors were hired to work on the project.

The terminal has three LNG trains with a capacity of 5.5 metric mtpa each. LNG is exported from the site on icebreaker-type vessels that can crush ice up to 2 meters thick.

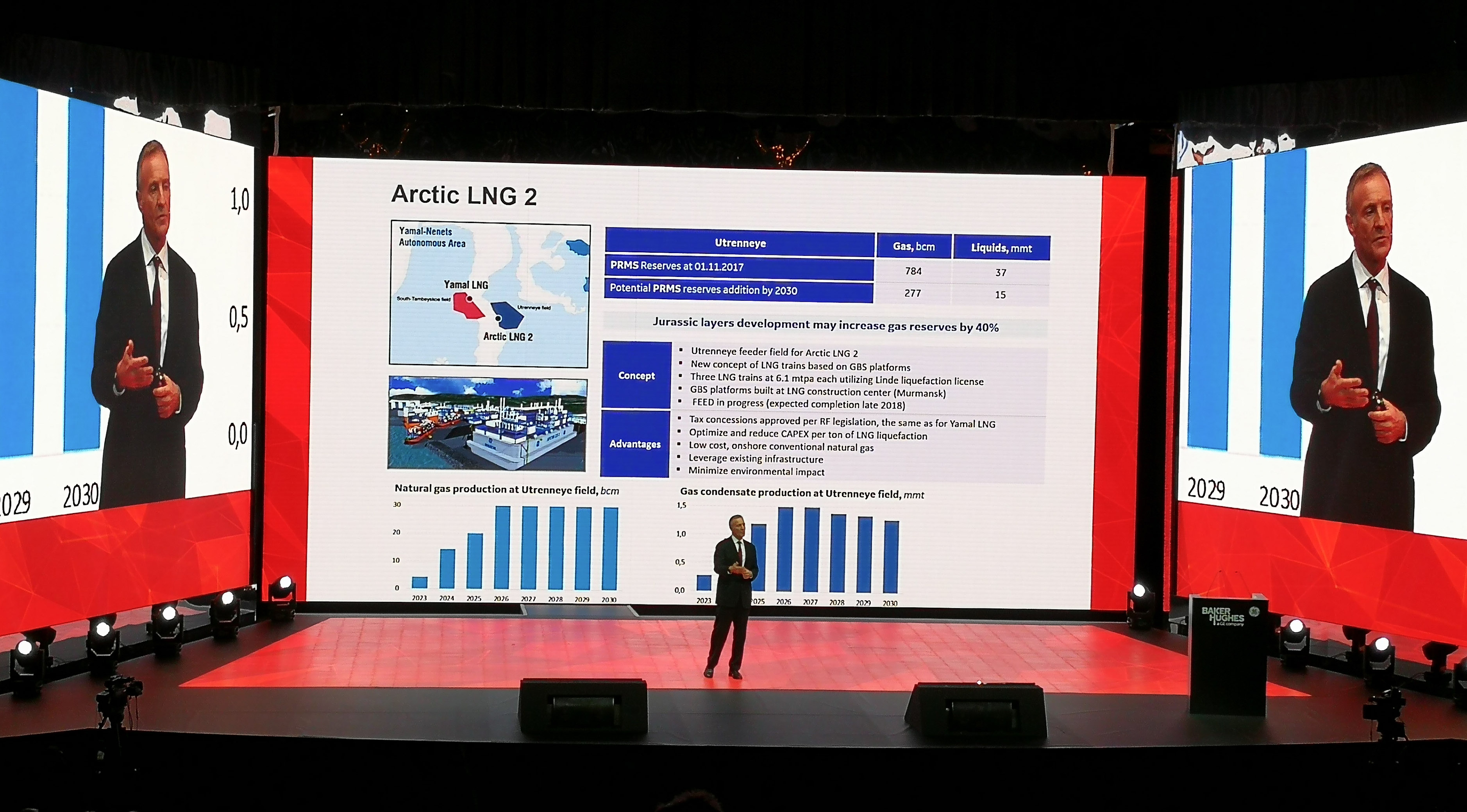

The Arctic LNG 2 project is based on a field that produces 30 Bm3y of gas and 1 mtpa of condensate. Rather than using pylons for this project, Novatek decided to build the terminal on gravity-based structure (GBS) barges.

The use of GBS systems will reduce construction costs for Arctic LNG 2 by 30% (or approximately $9 billion) from what was spent on Yamal LNG. Additionally, all of the field infrastructure for the project is connected by pipeline.

The LNG delivery method for Arctic LNG 2 will also differ from that used for Yamal LNG, Gyetyay explained. Rather than use icebreaker tankers to export the product, Novatek will build a transshipment facility in Kamchatka.

The facility will allow ice-class tankers to deliver LNG to Kamchatka, which will then be loaded on traditional tankers for export. The 20-metric MMtpy facility will have an expansion option to 40 metric mtpa.

By using technology and innovative solutions through collaborative partner relationships, Novatek plans to successfully monetize its resource base in the Yamal and Gydan peninsulas, lower the cost of liquefaction, increase the use of the Northern Sea Route for full-year navigation, create a new trading hub to serve the growing Asia-Pacific region, and adopt an LNG marketing strategy with flexible duration terms, pricing and volumes.

Related News

Related News

- Keystone Oil Pipeline Resumes Operations After Temporary Shutdown

- Freeport LNG Plant Runs Near Zero Consumption for Fifth Day

- Biden Administration Buys Oil for Emergency Reserve Above Target Price

- Mexico Seizes Air Liquide's Hydrogen Plant at Pemex Refinery

- Enbridge to Invest $500 Million in Pipeline Assets, Including Expansion of 850-Mile Gray Oak Pipeline

- Evacuation Technologies to Reduce Methane Releases During Pigging

- Editor’s Notebook: Nord Stream’s $20 Billion Question

- Enbridge Receives Approval to Begin Service on Louisiana Venice Gas Pipeline Project

- Mexico Seizes Air Liquide's Hydrogen Plant at Pemex Refinery

- Russian LNG Unfazed By U.S. Sanctions

Comments