May 2023, Vol. 250, No. 5

Tech Notes

Practical Preservation Strategies for Valves

By Cortec Corporation

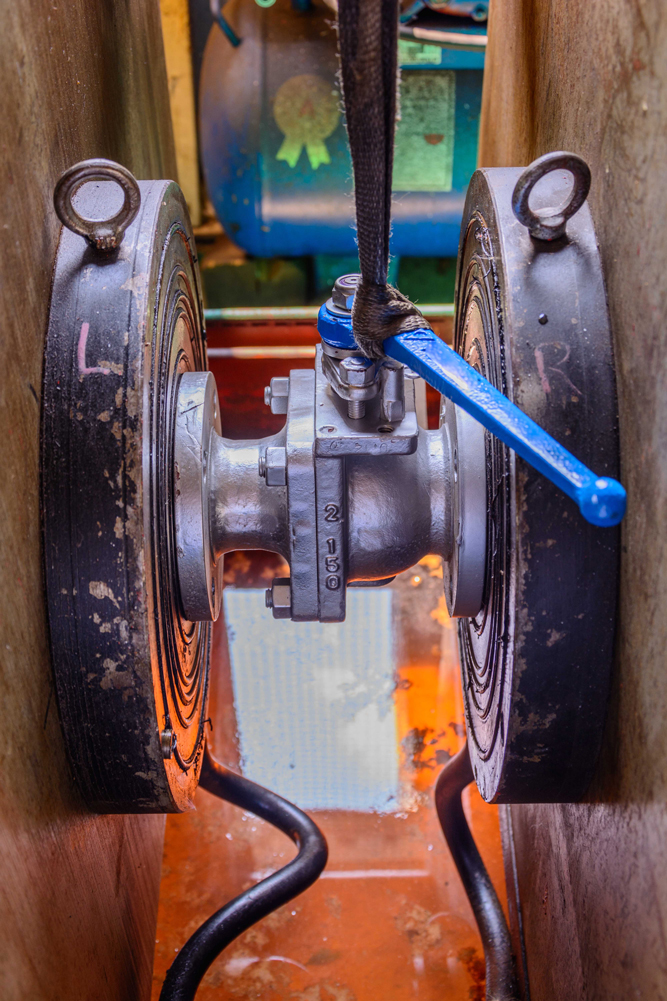

(P&GJ) — Ball valves, gate valves, globe valves, butterfly valves, check valves and valve assemblies: all these are common and critical components in the oil and gas industry. Their job of regulating hazardous fluid flow in pipelines and piping systems underscores the importance of keeping them in peak operating condition.

Unfortunately, one of the most common enemies of valve integrity is rust, which can attack and deteriorate valves during hydrotesting, shipping, and layup. The following tips from Cortec Corporation provide preservation guidelines during the three main phases of a valve’s non-operational life-cycle.

Phase 1: The Long Haul – Before a pipeline or plant starts operating, thousands of components must be fabricated, assembled, and shipped to the construction site. Valves must be hydrostatically tested by the valve manufacturer to ensure no leaks.

Hydrotesting of valves and components may also be done at coastal fabrication yards where components are assembled into modules and often shipped overseas halfway around the world.

Adding contact and vapor phase corrosion inhibitors along with anti-scalants to the hydrotest water does dual duty by protecting against flash rust from the hydrotest water and leaving behind a thin film of corrosion inhibitors that provide both contact and vapor-phase protection.

After internal protection, the entire valve can be enclosed in protective products for different atmospheric exposure conditions) to keep the inhibitors from escaping and to protect the external surface without cumbersome coating or liquid rust preventative application.

The valve is then ready to be shipped through all sorts of environments and arrive in like-new condition at the installation site.

Phase 2: Warehousing, Critical Spares – Another critical phase of valve preservation ought to occur during warehousing of critical or operational spares. Protection methods are similar to those previously mentioned, with slightly different underlying reasons.

For operational plants, preserving spare valves can mean the difference between millions of dollars saved, or millions of dollars lost for lack of a reliable spare to install when a replacement is needed.

If all spares are rusty (as too often happens in non-climate-controlled warehouses or outdoor storage yards), maintenance personnel must choose between installing a rusty, potentially faulty valve that could lead to further failure and disaster, or waiting and experiencing downtime for days, weeks, or months before a replacement arrives.

A much easier path is to “clean, protect, and preserve” valves in advance with these steps:

- Remove any existing rust, followed by rinsing and neutralization.

- Fog valve internals with fogging fluid.

- Cover openings or wrap the entire valve.

This procedure leaves valves in operating condition, ready to use at a moment’s notice as soon as they are unwrapped.

Phase 3: Mothballing, Layup – A third important phase of valve preservation comes when the fluctuating oil and gas market makes mothballing and layup the most cost-effective option, shutting down drilling or refining operations until there is a brighter industry outlook. In the meantime, millions of dollars of equipment must be preserved so that their value is not lost during the idle period.

Valves can be preserved in much the same way as other phases – ensure valves are clean and rust-free, add an internal source of Vapor phase Corrosion Inhibitors, and protect externals with a product such as VpCI Film, which has the appropriate degree of weather resistance.

Comments