March 2023, Vol. 250, No. 3

Features

Learning to Manage Risk of Over-Pressurizing Gas Pipelines

Special to Pipeline & Gas Journal

(P&GJ) — According to data from the International Energy Agency (IEA), in 2020, the world consumed 3.7 Tcf of natural gas. In other words, nearly 10 billion cubic meters of natural gas was transported daily from production sites to homes, businesses, and power plants worldwide through pipelines spread across millions of miles. Most of these pipelines operate underground, 24/7, quietly delivering a vital service to people across continents.

While pipelines remain the safest way to transport gas and are a crucial component of modern energy infrastructure, they are not without vulnerabilities. Safety has always been the number one priority for the natural gas industry, given the drastic impact any accident could have on public safety and the environment. No matter the size, any natural gas incident is one incident too many.

Take, for instance, the series of gas explosions that shook Merrimack Valley, Massachusetts, in September 2018. Caused by accidental over-pressurization of a low-pressure natural gas distribution system, the fires killed one person, injured 21, and forced more than 8,000 people to move out of their homes.

Unfortunately, the Merrimack Valley incident wasn’t an isolated event. According to statistics from pipeline authorities and a review conducted in 2019 by the Pipeline Safety Trust, incidents like the one in the Merrimack Valley have increased in frequency since 2010.

That said, the Merrimack Valley gas explosion was also unique for its scale and the seismic effect it had on the industry and pipeline safety regulations in the United States. Following this tragedy, and increased pressure from pipeline operators, the “Protecting Our Infrastructure of Pipelines and Enhancing Safety (PIPES) Act of 2020” (Pipes Act 2020) was passed by the United States Congress.

The PIPES Act includes several provisions to improve gas pipeline safety, including increased oversight and inspection of pipelines, stricter penalties for violations, and establishment of a national pipeline safety database. One of the key provisions of the Act is the requirement for operators to assess the risks that could lead to or result from the operation of a distribution system at a pressure (too low or too high) that makes the operation of any connected low-pressure gas burning equipment unsafe.

Regulating Pressure

Pressure regulator stations and devices have been used in the gas industry for over 200 years to control or regulate the pressure in the distribution network. In simplistic terms, downstream distribution networks are designed to operate at lower pressures. Failure to regulate gas pressure to appropriate operating levels can lead to catastrophic overpressure events or costly gas outages, which could impact the entire downstream network, potentially affecting thousands of customers.

“With the increasing focus on the reliability of supply and safety, gas utilities are ever more motivated to invest in and maintain the security of their infrastructure. At all costs, operators don’t want any incident caused by over-pressurization, which could cause damage to the pipeline network itself or, worse, result in explosions or leaks,” according to Kevin Hemingway, product manager at Synergi Gas & Synergi Liquid, DNV. “At the same time, they don’t want to risk the financial impact of an unplanned gas outage or supply interruption. Pressure regulator stations must maintain that fine balance consistently and constantly.”

Regulator stations are an essential, albeit complex, element of gas pipeline infrastructure. In case of an event, they can result in both localized and remote impacts across a gas network. This makes it essential for utilities to understand the risks, their probability, and how they will impact their customers to be truly prepared.

But, given challenges – such as differences in the station and regulator types and their many configurations, site-specific differences compounded by limited data, and multiple failure mechanisms in regulator stations – traditional risk management methods and models are often inadequate.

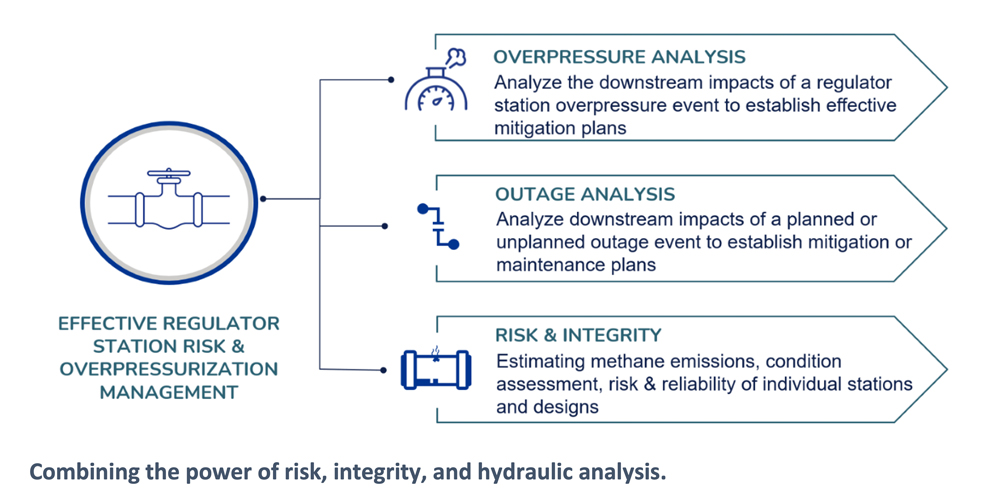

Stronger Together

The secret to robust regulator station risk and overpressure management is to combine the power of risk, integrity, and hydraulic analysis. Integrity and risk analyses are critical to evaluate the condition, assessment, and reliability of each regulator station in a network. On the other hand, hydraulic analyses complement this evaluation and help assess the impact and magnitude in case of an overpressure or outage event and arrive at mitigation measures to reduce or eliminate those consequences.

Today, operators often use basic risk models and default consequence values to model regulator station risk. But Guanlan Liu, a senior engineer with DNV, explained the need for a focused, combined approach.

“The hydraulic model allows you to identify factors such as impacted customer count and overpressurized pipeline length, at each regulator station in a network,” he said. “Juxtaposing this information with the integrity data, such as the probability of failure at each regulator station, the probability of ignition and the home regulator reliability, allows the operator to estimate how many customers would be injured in case of an overpressure event at a specific regulation station.”

Effective Management

The Overpressure Analysis and Outage Analysis tools in Synergi Gas analyze the impact of an event, while the integrity and risk management software, Synergi Pipeline, assesses the stations, based on reliability, probability of failure, and potential impact. When used with the company’s other probabilistic models, it provides visibility of the regulator station risk liability versus other asset classes, such as main and service pipes.

Combining the power of risk, integrity, and hydraulic analysis.

The pairing of risk analysis and hydraulic products creates a solution with increased value for both system planners and integrity engineers, designed to save time and improve efficiency. It automates hydraulic analyses for each station and uses reliability mathematics to calculate failure probability.

Additionally, it presents the information in an interactive format, making it easy for operators to derive critical insights and run what-if analyses. This includes creating a map of stations across the network that allows the operator to click on a location and identify its risk value.

The solution also allows operators to effectively analyze risk across all stations, rank them, and prioritize resources accordingly. By combining the likelihood and consequence of failure, the tool provides them with a clear gauge of potential damages. Engineers can use this information to identify the highest risk regulator stations and implement mitigation measures such as overpressure protection, replacement of outdated regulators and increased inspection frequencies through asset management programs.

Comprehensive Strategy

An early adopter, one of America’s largest operators, took learnings from the Merrimack Valley pipeline explosion and implemented DNV’s comprehensive solution to assess both the risk of leaks and ruptures of each station and the risks associated with overpressure and outage events caused by the stations. Experts from DNV worked in close partnership with the operator to create a risk model that accounted for each regulator station’s configurations and associated historical operational reliability.

The operator has since reported a significant improvement in their ability to make better decisions regarding maintenance, upgrades, and replacement of regulator station equipment. They see the solution as critical to their capital spending planning process and as an aid to ensure those plans are based on risk and defensible to the state regulators and their ratepayers.

Overall, the solution helps the operator:

- Meet DIMP (distribution integrity management program) regulatory requirements, including PIPES Act 2020

- Evaluate the consequence and impact on customers

- Identify the highest-risk regulator stations and station types

- Understand regulator station risk in comparison to other assets when used in conjunction with DNV’s other probabilistic models

- Drive mitigative measures based on risk through DIMP

- Guides future regulator station design and construction

Ahead of Curve

The impact of an overpressure incident on public health,safety, property and business can rack up significant expenses for operators, not to mention the impact it would have on public perception and the social license to operate.

Therefore, being proactive in understanding the risk across a system is becoming increasingly critical as utilities look to prioritize efforts and expenses. DNV’s approach to overpressure management can help utilities focus efforts in the most critical areas in the most effective manner, optimizing money spent and ensuring safety while complying with regulations such as the PIPES Act of 2020 and other industry standards.

As the focus on pipeline safety increases, stricter regulations demand better solutions – a comprehensive solution is key to improving performance, increasing efficiency, and protecting lives and the environment.

Comments