September 2022, Vol. 249, No. 9

Features

Being Certain of Flow Measurement Meter Uncertainty

By Bruno Pinguet, Senior Advisor, TÜV SÜD National Engineering Laboratory

For many years, the oil and gas industry has widely believed that the production test separator gives the most accurate flow rate measurements. However, realistically, it’s unlikely to be used because of the sheer size of a separator, which creates mobility issues such as the need to lift it with cranes and a requirement for ruggedized equipment for shocks and vibrations.

However, the alternative smaller and more commonly used well test separator will always be below expectation in terms of flow rate measurement accuracy. Some industry standards, therefore, have been created to mitigate against the poorer performance of well test separators, such as a consensus on the minimum residence time of around one minute.

In recent years, many devices have been added inside the test separator to reduce turbulence, facilitate the coalescence, reduce the carryover with some demisting devices, etc. Another restriction of the test separator is that the fluid coming out of each single-phase line must always remain in the relevant range of the single-phase meter being used as a reference on the gas line, such as a multiple set of orifice plates or Coriolis flowmeters following the expected flow rates.

The same series of devices are also necessary on the liquid line with multiple positive displacements, turbines or Coriolis of many sizes. The list is not exhaustive but shows the number of devices that are required to maintain nominal conditions for accurate measurement, even if the separation is optimal.

Multiphase Flowmeters

Multiphase flowmeters (MFMs) have been used as complex measurement systems for the oil and gas sector for many years. Since they can eliminate the need for a test separator, which is big and difficult to maintain, smaller platforms are possible. Existing facilities can also be upgraded to take subsea tiebacks without having to add an extra test separator.

MFMs also give continuous measurements, allowing better reservoir management, well optimization and a quick response to water breakthrough and similar events.

Because MFMs are becoming drastically cheaper, most oil and gas operators could now take advantage of this capability. However, while they reduce CAPEX, fundamental questions remain regarding the reliability and capability of such equipment to perform accurately when compared to previously used systems.

This is because the claimed theoretical uncertainty of meter manufacturers does not always match that of a more conventional test separator setup, making some oil and gas companies question their accuracy in service.

The buying process often involves regular comparison tests being made either before delivery, later in the field or as a spot-check against standard equipment, such as separators.

While flowmeters are calibrated under ideal laboratory conditions, the environments in which they are installed vary greatly. Today, in this billion-dollar oil and gas industry, it is incredible to see that most flow measurement systems are reporting flow rates with no consideration of measurement uncertainty.

Uncertainty analysis is essential, therefore, to determine whether measurement systems can meet required performance targets.

What Is Uncertainty?

It is a popular misconception that measurement is an exact science. All measurements are merely estimates of the true value being measured, and the true value can never be known. The oil and gas industry also misuses the terms “accuracy” and “uncertainty.”

Accuracy refers to the agreement between a measurement and an expected true value. Therefore, accuracy requires two measurements with two different meters. Accuracy cannot be discussed meaningfully unless the true value or most probable value is known or can be recognized.

On the other hand, uncertainty is an interval defined around the average, which is based on the data collected over a period that is considered a stable flow condition. The true value can be expected to be within the confidence level defined during the measurement.

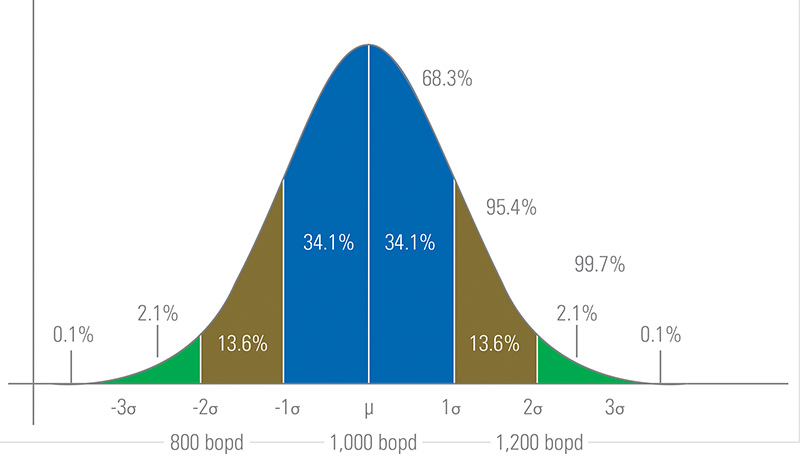

The size of the interval is described as a confidence interval or in terms of sigma (i.e., standard deviation from a statistical point of view). To make MFMs easily comparable and effectively report their performance, the multiphase flow metering community follows the 95% confidence level, or 1.960 multiplied by one sigma.

From a practical point of view, this means that when a measurement is made repetitively (under continuous stable flow), then a standard deviation can be calculated using the numerous collected data.

This is defined as 1 sigma (σ), which means that there is a 68% chance that the true value is within this interval. This standard deviation “σ” is multiplied by 1.960 and provides the performance or uncertainty interval with a 95% confidence interval.

So, how can operators effectively allow for this uncertainty? The ideal approach would be to calibrate each individual device for the specific conditions it will encounter. However, this is not financially realistic. To establish the performance of an MFM, an uncertainty budget must be constructed, considering additional uncertainties arising from interpolation and extrapolation from calibration conditions.

First, calibration against a single-phase meter of at least three to four times better than the device in question is needed. A third-party flow loop facility, the best being a primary calibration facility, does this. Second, the repeatability performance of the MFM must be established.

The repeatability of the device-under-test (effectively, the closeness of agreement between successive measurements made under the same conditions) is an estimation of the overall uncertainty of the calibration. The repeatability is demonstrated by maintaining the flow conditions of operation and simply switching the device off and on. Any deviation that appears will need to be considered as repeatability.

Reproducibility is another essential parameter from the end-user’s point of view. This is established by moving from a given condition, such as pressure or choke opening, etc., to different conditions and then returning to the previously given conditions.

Meter drift is a systematic uncertainty that also should be accounted for because this determines how the error in the measurement process will change over time. Bias is very well documented and addressed in ISO 21748, and it could be a source of uncertainty.

Stability is another parameter to consider, because if there have been multiple calibrations of the same flowmeters over the years, this will be the standard deviation of the calibration results. The standard uncertainty and the associated stability of the reference measurement should also be considered.

Proper Comparison

To establish the performance of an installed MFM against a reference flowmeter, some prerequisites are necessary. For example:

- Both devices must be physically as close as possible, so changes between them in line pressure and temperature are minimal.

- Both devices must record data at the same time.

- Both devices must use the same pressure-volume-temperature (PVT) package to perform the conversion from line to standard conditions, or from the MFM conditions to reference flowmeter conditions.

- If the devices are far from each other, the cumulative volume measured must be three times larger than the storage volume between both flowmeters. The longer the recording, the more accurate the established uncertainty of both devices will be.

- If the devices are far away and the flow reaches the MFM long before the other device, then the reference flowmeter recording time should be defined to capture the same type of flow passing through both meters.

- No choking should occur between both devices to keep the PVT package consistent and for the quick evaluation of the line or standard conditions of both devices.

Having spent nearly 30 years researching and developing multiphase flowmeters, I understand the commercial benefits MFMs can deliver. However, acceptance within the oil and gas sector is slow, with slightly over 10,000 units having been sold by about 20 manufacturers today.

I estimate that this represents over 95% of the total market. To ensure the validity of an MFM’s measurements, comparison tests should be conducted either during the buying process, before delivery or later if results do not match client expectations or reservoir model forecasts.

A third-party familiar with field well test operations can validate test comparisons in well-controlled conditions. This helps to avoid any conflict about who is right or wrong and provides a clear, final statement based on statistical analysis, physics and field expertise.

Author: Bruno Pinguet, is Multiphase Domain senior advisor at TÜV SÜD National Engineering Laboratory, which is a world-class provider of technical consultancy, research, testing, and program management services. Part of the TÜV SÜD Group, it is also a global centre of excellence for flow measurement and fluid flow systems and is the UK’s Designated Institute for Flow Measurement.

Comments