December 2022, Vol. 249, No. 12

Features

PRCI President’s Report: Celebrating 70 Years, Looking to the Future

By Cliff Johnson, President, Pipeline Research Council International (PRCI)

(P&GJ) — The founding of the Pipeline Research Committee (PRC) within the American Gas Association in 1952 was a key stepping stone for the natural gas pipeline industry. When a small group of pipeline engineers came together seeking solutions for one key issue facing the industry, they already knew that they were not able to solve the problem individually

By working together, sharing experiences, and researching the issues collaboratively, they found not only a solution to the ongoing issue sooner than they ever expected, but they also realized the need for establishing permanent opportunities for sharing common operational challenges and developing the research needed for solutions.

Seventy years later, the mission to collaboratively deliver relevant and innovative applied research to continually improve the global energy pipeline systems has never been more important.

The Past

In the first two decades after the founding of PRC, collaboration continued to be successful. In the 1970s and 1980s, PRC produced some of the earliest research for the transport and storage of hydrogen. These results from many of the building blocks used in the current research to enable the inclusion of other fuels into our current pipeline assets.

During these decades, PRC released industry defining research focused on the theoretical model for crack propagation and arrest in pressurized pipelines (NG-18) and Residual Strength Assessment and Residual Life Prediction of Corroded Pipelines (RSTRENG).

These documents are key reports for ensuring the remaining life and fitness for service of the global pipeline infrastructure. RSTENG is required by the Pipeline & Hazardous Materials Safety Administration (PHMSA) to evaluate the remaining strength of corroded pipe.

As the value of PRC became increasingly apparent to the industry, membership in the 1980’s grew to include non-North American operators, the first of which was Gasunie, a Dutch pipeline operator.

Knowing the challenges facing pipelines are universal and to leverage the pathways to solutions globally, PRC established a partnership with the European Pipeline Research Group (EPRG) to share knowledge on a regular basis to advance the safety and integrity of the pipeline infrastructure. The Pipeline Research Committee had become an international organization.

Throughout this time, research was advanced by the creation of technical subcommittees whose expertise ranged from corrosion to subsea. It should come as no surprise that the committees changed and were modified over time to address the key challenges that the natural gas pipeline industry faced.

Even today, the commitment and technical expertise of its members continues to develop dynamic, PRCI research programs devoted to identifying, prioritizing, and implementing the industry’s core research.

The Present

In 2000, PRC and AGA established an independent organization, Pipeline Research Council International (PRCI). Five years later, the inclusion of five liquid pipeline operators and the Association of Oil Pipe Lines (AOPL) as PRCI members now encompassed the safety and integrity of pipelines that transport natural gas, liquids, biofuels, and hydrogen as well as their related facilities.

PRCI became the only research-focused association anywhere in the world with such a diverse portfolio. This progress also gave PRCI the unique responsibility of defining and executing the needed research program to advance the industry.

Technology Development Center

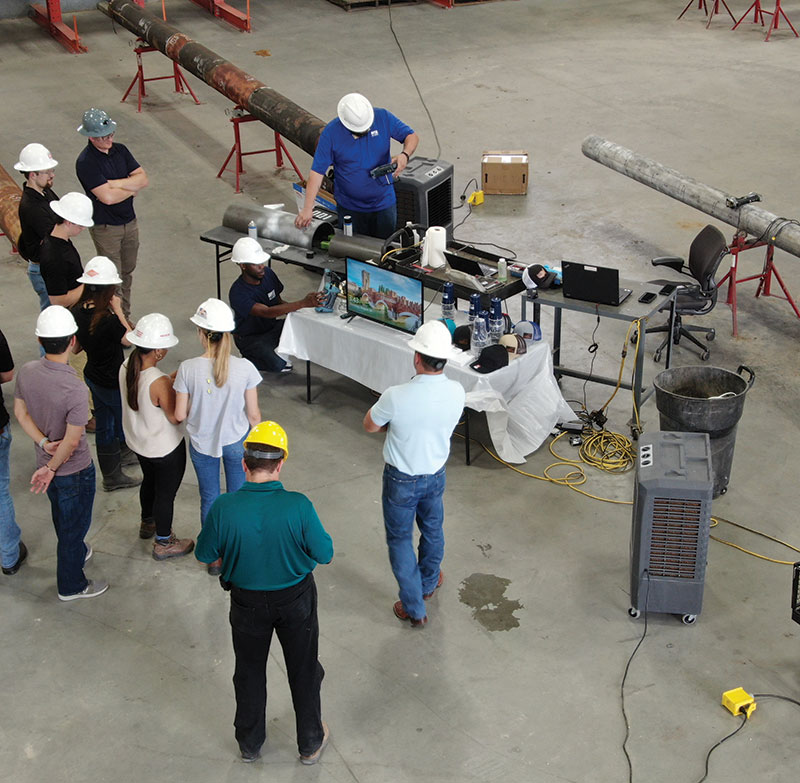

With such a diverse research portfolio, PRCI then facilitated a major commitment by the energy pipeline industry and built the Technology Development Center (TDC) in 2015 in Houston, Texas, to ensure the safety of the national and international pipeline systems. Having a single location able to accumulate former in-service pipe materials with real-world pipeline features and flaws is invaluable to both PRCI’s R&D program and the industry. It provides a central point for hosting industry-sponsored training and workshops to advance the personnel needed to support the industry.

Located over eight acres, the TDC includes a 5-acre, state-of-the-art pull test and flow-loop facility, and a workshop and test facility that is over 20,000 square feet with an additional 9,000 square feet of office and meeting space.

Together, this provides the industry with an independent third-party site to fully understand the capabilities of current tools and to guide the development of the new technologies needed to push towards the goal of zero failures.

Research Objectives

The continued need to prioritize and execute key research initiatives in a timely manner established formalized research objectives (RO) in 2018. The ROs provide the guidance needed to focus PRCI members on a unified and collaborative research agenda with key industry drivers to focus on technology transfer, implementation of results, and a wide application of outcomes.

As identified by the PRCI membership, the nine ROs are to:

- Develop and/or validate technology and analytical processes capable of confirming pipeline material properties for pipeline integrity assessments.

- Develop and enhance ILI technology to reliably detect, size and characterize specific indications that may be harmful to the integrity of the pipeline.

- Develop, evaluate and enhance NDE technologies and operator and data analyst performance to assess the integrity of pipelines and associated infrastructure from outside or above the pipeline or facility.

- Confirm the fundamental integrity and safe operation of vintage pipelines by expanding the applicability and reducing the uncertainty of Fitness for Service methodologies, including defining critical feature dimensions, associated models and response criteria.

- Develop, demonstrate and validate repair systems, including those that can be deployed on in-service facilities. Determine the useful life and safe operating envelopes of such repair systems.

- Develop, demonstrate and validate intrusion monitoring and surveillance technologies to enhance detection of third-party activities, ground movement and interferences potentially affecting pipeline infrastructure.

- Reduce all product leaks and equipment emissions from all parts of the hydrocarbon transport and storage infrastructure by developing, demonstrating and validating processes and technologies to detect, quantify and mitigate such releases.

- Improve the efficiency, operational flexibility and availability of compressor and pump station, measurement and storage facilities. Reduce the lifecycle cost of these facilities as flow patterns and market demands shift. Reduce custody transfer uncertainty and better identify trace gas constituents.

- Define, understand and improve the key practices, including models, involved in the design, construction and integrity management of pipelines and related facilities.

This rich, productive history of research lead by technical committees has played a significant role in advancing the industry to 99.999% safe. However, to achieve the goal of zero failures, PRCI needed to reimagine how research is organized and looked across the research portfolio to solve deeper challenges.

Research Priorities

Strategic Research Priorities (SPR) are a method to identify critical industry challenges and enable PRCI to provide a three-to-five-year focus to drive to a significant conclusion. Established in 2019, identifying and executing SRPs allows PRCI to address key strategic industry initiatives and issues in which there are near term opportunities to develop significant outcomes for the industry and for the interest of the public.

Focusing efforts and funding to address significant industry challenges demonstrates PRCI’s continued recognition of the current state of the industry and the position that it has in providing the key solutions needed to enhance the safety and integrity of our global pipeline systems. SRPs allow PRCI to lead industry research by making impactful advancements in technology and R&D. Collectively identifying and executing SRPs improves industry response, efficiency and engagement by being more strategic and intentional about breaking down silos and working cohesively as a larger committee to solve problems that cross disciplines.

Currently, there are four approved SRP focuses. These topics represent some of the key challenges facing the energy pipeline industry:

- Optimize the detection and mitigation of the impact of mechanical damage

- Greenhouse gas emissions reductions

- Pathway to achieve effective and efficient crack management

- Advanced leak detection

Completion of the Mechanical Damage SRP will occur in 2023 and provide guidance to the industry on how to address defects associated and ensure the fitness service of the lines is already formed. Members have already been able to implement findings. The Greenhouse Gas Emissions Reductions and Crack Management SRPs will finish in 2024. The Advanced Leak Detection SRP was approved in September of this year.

Emerging Fuels Institute

As the world’s resolve to reduce anthropogenic environmental disruption grows, PRCI has strengthened its environmental commitment. Low carbon footprint fuels are a key component of a sustainable energy society. With energy transitions expected as early as 2026 in some parts of Europe to 2050 throughout much of the United States, the goals demand collaboration with industry stakeholders to optimize the overall transition effort.

Established in 2021, the Emerging Fuels Institute (EFI) is working to solve the technical gaps that exist as the industry transitions to low carbon energy solutions using the existing pipeline asset infrastructure.

Collaboration with industry stakeholders is critical to ensure the optimization of the overall transition effort. To ensure a comprehensive and continued awareness of ongoing work within the industry, a key task of the EFI is partnering with peer research associations to share respective research roadmaps so that work is efficiently and comprehensively incorporated into the deliverables of the EFI.

Global peer partner associations currently include:

- Australian Pipeline and Gas Association (APGA)

- European Pipeline Research Group (EPRG

- European Gas Research Group (GERG)

- Future Fuels Collaborative Research Center (FFCRC)

- Gas Technology Institute (GTI)

The EFI coordinates it efforts with governmental agencies such as the Canada Energy Regulator (CER), the U.S. Department of Energy (DOE), and the U.S. Pipeline and Hazardous Materials Safety Administration (PHMSA). Technical society partnerships include the Canadian Standards Association (CSA) and the American Society of Mechanical Engineers (ASME).

Partnering industry associations include:

- American Gas Association (AGA)

- Association of Oil Pipe Lines (AOPL)

- American Petroleum Institute (API)

- Interstate Natural Gas Association of America (INGAA)

The scope of the EFI addresses hydrogen and renewable natural gas (RNG).

Current priorities follow market focus in the storage and transportation of hydrogen and RNG. Project emphasis areas include:

- Integrity of pipeline system steel and non-steel components

- Compressor stations and facilities

- Pressure control and over-pressure safety devices

- Design requirements for electrical classification and fire safety

- Downhole reservoir and cavern storage

A key output of the EFI will be the development of a guide to safely convert and operate pipeline systems to allow for the transport and storage of the next generation of fuels.

Recently, the EFI completed white papers the provide clarity on the issues that need to be addressed by research to ensure the safety and integrity of the pipeline infrastructure for Hydrogen and Hydrogen Blends.

CO2 Task Force

Expanding upon PRCI’s environmental commitment led to the development of the CO2 Task Force.

The U.S. Department of Energy Fossil Energy and Carbon Management Office recently stated there is “no way to decarbonize entire economy by 2050 without carbon capture and sequestration.”

Carbon capture, utilization and storage will need to increase tenfold by 2030. There is a need to grow the existing 5,000 miles of the CO2 pipeline in the U.S. to 11,000 by 2030. A minimum of 50,000 miles will be required by 2050 in addition to the need for storage of more than 1 billion metric tonnes of CO2 per year.

With this defined opportunity, PRCI created the CO2 Task Force to enable the industry to meet these pressing needs while continuing to ensure the safety and integrity of the pipeline and storage network. The CO2 Task Force is currently developing a state-of-the-art report to clearly define the research opportunities. The report will be complete in the first half of 2023.

VTDC

PRCI has embarked on a new effort to build upon the vast industry learnings and data developed to assist in bridging the gap from 99.999% to 100% safe and efficient pipelines. The Virtual Technology Development Center (VTDC) is a virtual center for industry members to develop technology-based solutions for operating problems in the energy pipeline industry through data collected and shared information/learnings.

The safety and integrity of the global energy pipeline system relies upon detailed analysis of relevant data leading to informed decision making. Shared learnings significantly improve the ability to perform this critical analysis.

The platform, opening in the near future, will host databases which will allow users to utilize anonymized data and information from multiple projects that have been standardized across projects and sources.

As the energy pipeline industry moves toward the next generation of fuels, pipelines will continue to be the safest and most efficient system for transporting and storing these new energies. PRCI’s 70 years of applied research results is a solid foundation upon which to continue improving the integrity of the current infrastructure while transitioning to a low carbon future.

Looking forward to the next 70 years, there is still much to be done. There are many opportunities to strengthen the current pipeline infrastructure and develop the next generation of the infrastructure. Be a part of the future: join PRCI and the efforts to develop the solutions needed to make the safest and most efficient pipeline infrastructure. Be part of the solution!

Comments