October 2021, Vol. 248, No. 10

What's New

What's New October 2021

Vermeer

Vermeer upgraded its truck-mounted vacuum excavator line with the new VXT300 truck vac, which is outfitted with an 8-cubic-yard (6.1-cubic-meter) spoil tank, 6-inch (15.2-cm) dig tube and the ability to carry up to 800 gallons (3,028 L) of water so crews can maximize productivity on the job. It is one of the lightest truck vacs in its class, designed with a low overall height of just 11.5 feet (3.51 meters). Built on a Kenworth T370 truck chassis with a 350-hp (261-kW) diesel engine and a 6-speed automatic 3,000 RDS Allison transmission, the truck’s PTO drive powers its Roots 624 vacuum blower with a maximum flow of 3,500 cubic feet per minute (99 cubic meter per minute) and maximum suction of 18 inHg (0.6 bar). With a water pump capable of producing 10 gallons per minute (37.9 liters per minute) at 3,000 psi (206.8 bar), the VXT300 delivers productivity on large jobs as well as when digging at deeper depths. www.vermeer.com

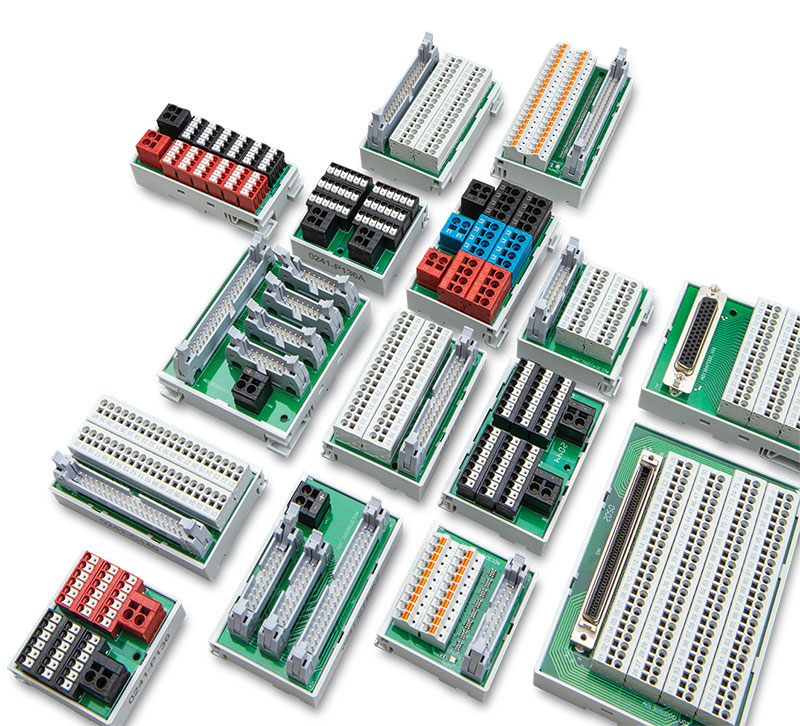

Dinkle

Dinkle International released its complete line of interface modules, to simplify and improve reliability of automation connections and signal conversions, in a compact form factor. Instead of being constrained to standard factory wiring arms and bulkier terminal blocks, users can gain flexibility selecting from a range of universal interface modules and associated cables, which are available with popular industry-standard connectors like IDC (14-pin, 20-pin, 26-pin, 30-pin, 34-pin, 40-pin), D-Sub (37-pin, 44-pin), MDR (50-pin, 68-pin, 100-pin) and terminal blocks. Other available features include available LED status indications for termination points, provisions for clear marking and color coding, reverse-polarity protection in some models and extra-slim relay options for providing signal isolation. www.dinkle.com/en

NDT Global

NDT Global released its OPTIX Data Visualization and Insights Platform, providing pipeline operators with an intuitive, cloud-based dashboard to visualize all inline inspection (ILI) data in one accessible location. Digitization of the final inspection report, combined with the ease of filtering and arranging relevant data, allows operators to better understand their ILI inspection results and make more informed decisions to ensure the integrity of their pipelines. The platform provides a comprehensive view of pipeline conditions not previously available, bringing together results from many inspection runs. Continued advancement in ILI technologies has led to significantly more data to extract and interpret. www.ndt-global.com

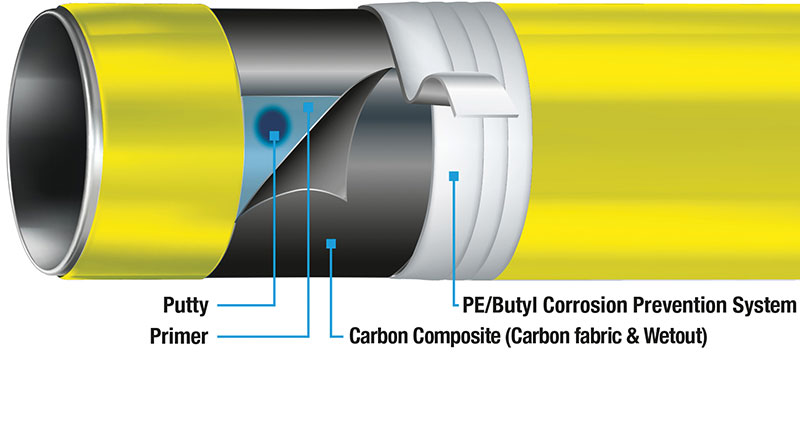

Dekotec

Dekotec GmbH offers Dexpand-CF70, which repairs damaged sections of steel pipes and restores the structural integrity, returning them to their original level. The carbon composite repair system can repair pipeline during ongoing operations. The system can provide a saving of about 75%, and take about half as long, Dekotec said. It is suitable to repair defects in which up to 80% of the original wall thickness has been lost. The system is suitable for operating temperatures of up to 70 degrees C (158 degrees F). www.dekotec.com.

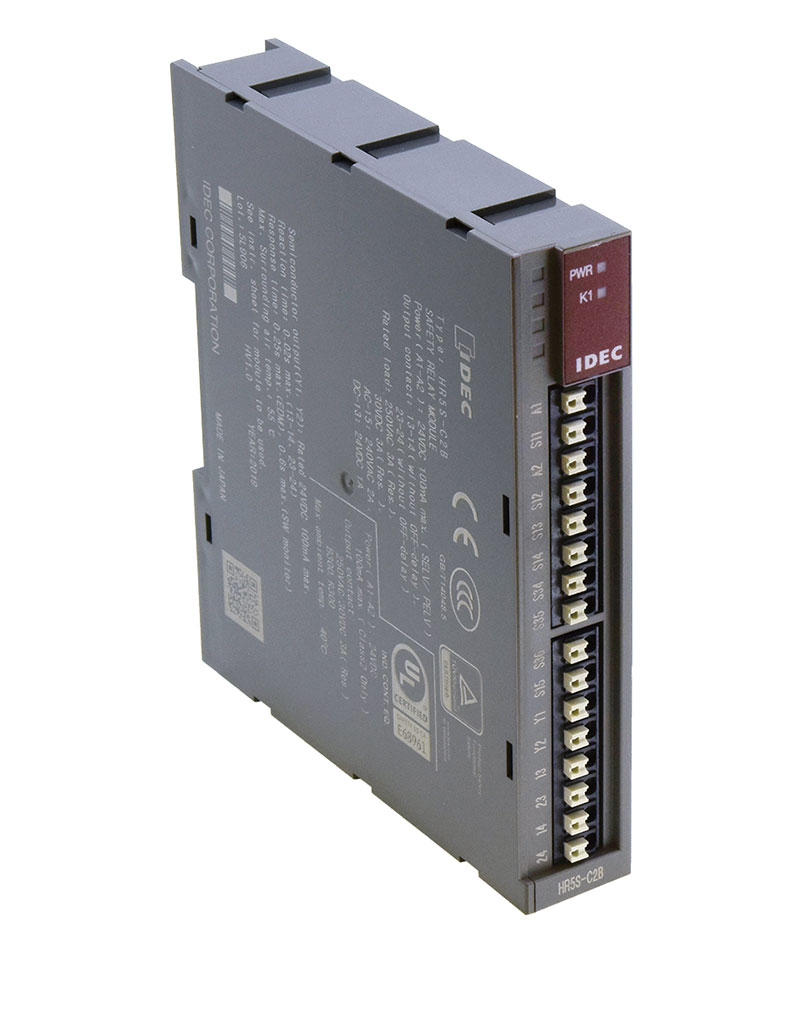

IDEC

IDEC Corporation released its HR5S safety relay module, which is designed to provide better safety options, while cutting costs and improving the productivity of machines and equipment. Safety relay modules, like the HR5S, are a key component for interlocking equipment and driving it to the safest possible state in case an emergency stop pushbutton or other safety input signal is activated. HR5S safety relays are available in three configurations for a range of applications. The simple type can be used for applications up to PLc, while standard and off-delay types work well for designs up to PLd and add failure detection features. While most Category 3 and higher relays consume 1.8 inches (45 mm) of installation width, the HR5S is only 0.89-inches (22.5-mm) wide and can be mounted on DIN rails or a back panel surface. www.idec.com

OleumTech

OleumTech launched its electromagnetic flow meter as part of its H Series hardwired process instrumentation line. The OleumTech HEFM Magnetic Flow Meter offers polytetrafluoroethylene (PTFE) lining material, a backlit local display interface and various self-diagnostic features for managing critical device health. The HEFM flow meters can be custom ordered using a variety of line sizes, materials and power options to fit the needs of OleumTech end users.

Highlights include independent measurement of fluid density, viscosity, temperature, pressure and conductivity, two measuring points inside the meter with no moving parts, reference accuracy: ±0.2% of reading, output signal options: RS485 Modbus / 4-20 mA / 2-8 kHz pulse output and a backlit LCD with integral push-button interface. www.oleumtech.com

Comments