April 2021, Vol. 248, No. 4

Features

Edge Computing Optimizes Pipeline Management

By Corie Allemand, Global Leader for Oil and Gas, Stratus Technologies

Operational excellence, productivity and safety performance are top priorities for the midstream oil and gas industry. Corporate leadership is seeking increasingly different ways how to adopt industrial internet off things (IIoT) efficiently and quickly and digitalization solutions to be more agile in a competitive environment.

Edge computing supports data management and analytical capabilities, which improve enterprise and industrial asset management. The unique structure of midstream operations is well suited to apply edge-computing solutions.

For midstream oil and gas companies, edge-computing platforms create opportunities that resolve long-standing problems and effectively enable real-time data in asset management and decision-making,

Edge Operations

For midstream operators, operational excellence is at the “edge.” Data acquisition is characterized by remote, decentralized assets and infrastructures (pipelines and terminals), and associated equipment (pumps, compressors, valves, sensors and other devices) at numerous locations. It is a complicated network with many moving parts.

These assets and equipment must be managed in real time with limited resources and personnel. More importantly, new digitalization projects must solve long-standing problems (Table 1).

Midstream oil and gas companies have assembled and stored pipeline operations data for many years. IIoT and digitalization innovations give midstream oil and gas pipeline operators greater capabilities to gather and analyze ever-growing volumes of data.

Consequently, operators can act upon insights gained from that data and manage their infrastructures more effectively and efficiently. IIoT, digitalization and edge computing provide opportunities to resolve operation problems.

New Tools

Digitalization is the use of technologies to collect, process and analyze data in near real time and to provide value-producing and cost-saving opportunities. These digitalization tools give oil and gas pipeline operators visibility across the entire midstream infrastructure, allowing them to remotely monitor pipeline conditions and equipment health (availability).

Digitalization tools aid in translating numerous real-time data points into usable information that can be acted upon in a timely manner. These solutions remedy latency problems (Table 1) that seriously affect pipeline operators’ abilities to take appropriate corrective actions in near real time.

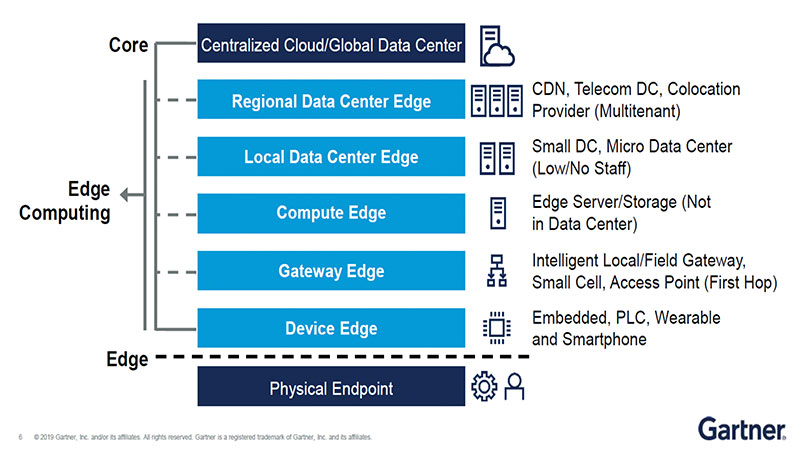

Edge computing is a new development. It is a distributed computing environment in the oil and gas segment. The infrastructure provides computing capacity and data storage to the pipeline equipment and machinery where it is needed. Computing devices at the edge will also typically secure the machinery and the equipment they control.

Edgecomputing

As illustrated, edge computing is ideal for real-time data collection, analytics and industrial asset management. Edge-computing hardware collects equipment data locally and can act upon that data locally, reducing latency concerns. Data can also be accessed remotely or be sent to the data center.

A well-managed edge-computing infrastructure will use digitalized IIoT platform solutions to gather and analyze data from industrial equipment and machinery.

With real-time data, informed decisions keep midstream operations running efficiently and effectively. For midstream oil and gas operators, knowledge at the asset level is critical to various operations, such as:

- Terminal/pipeline operations and control

- Critical equipment condition monitoring

- Predictive (planned) maintenance

- Health, safety and environment (HSE) management: prevention of unplanned shutdowns, leaks, equipment failures and more

Building for Tomorrow

Failure in industrial digitalization projects is largely attributed to a lack of understanding of how to apply a digital program to a particular operation.

Incomplete knowledge about edge computing, industrial management platforms and limited in-house expertise often stall such projects at conception and end further development. In 2019, an estimated 70% of digitalization projects failed to achieve stated goals.1

Before selecting a vendor or technology to implement a pipeline management program, midstream companies must develop a living strategic plan that balances the requirements of present operations and includes manageable guidelines.2

The “big ideas” from improved data collection and access are the capability for predictive knowledge and action. In a recent survey, respondents indicated that artificial intelligence (AI), machine learning, digital twins and predictive maintenance are high-priority achievements.3

All require significant numbers of quality data pairs to conduct higher analytic investigations. Edge-computing strategies enable oil and gas operators to capture real-time data and harvest knowledge for operational excellence.

Predictive maintenance models provide significant payback.4 Through edge-computing platforms, early (real-time) detection of abnormalities affecting machinery, pipelines and tanks can initiate preventive maintenance responses. Midstream oil and gas companies can use preventive maintenance to minimize repair and replacement costs, reduce downtime and prevent accidents and product releases.

Edge computing supports forecasting when maintenance should be done to avoid decreased operations and equipment efficiency. Midstream companies can integrate edge computing strategies into safety initiatives for transport and logistics and increase pipeline and equipment availability.

Future Proofing

Looking forward, oil and gas companies need to build an industrial digitalization strategy. For long-term sustainability, the plan should be a living approach that balances operational requirements within manageable guidelines.2 Midstream companies should invest in technologies that automate data management and governance at the edge as much as possible.2

The ability of edge-computing platforms to run multiple applications on a single, high-availability node through virtualization provides quick and cost-effective solutions.

Edge computing is an ideal foundation to accelerate the digital transformation and achieve corporate goals, including improved safety performance, better decision-making, greater visibility across the network and reduced downtime.

Successful industrial digitalization projects must focus on sustainable operation and productivity over the long term while protecting data, people and valuable midstream assets.

As more data are collected, a hierarchy is needed to determine what to keep at the edge and what to send on to the data center.

The recent COVID-19 pandemic reinforces the growing need for remote access to assets and data and a greater use of “zero-touch” devices and applications. Edge computing is a viable solution to further connect devices, secure data, provide real-time decision support and apply advanced analytics for assets and equipment outside the fence.

Present challenges in pipeline management and data security include:

- Critical assets are remote with limited staffing. Operators and technicians need the capability to collect real-time data directly from remote equipment and convert it into actionable information. A pipeline may use one server for 1,000 miles (1,609 km) of pipeline without individual computing support. Traditional data centers are not a solution for pipelines.

- Acquisition of pipelines creates legacy IT infrastructures and systems, which can become a maintenance issue. Consequently, such developments create inflexible systems that will be difficult, if not impossible, to integrate with Industry 4.0 technology. Unfortunately, IT teams are caught in “patch and update” cycles. To do routine maintenance, IT staff must visit locations and are exposed to high-risk, hazardous environments.

- Mission-critical applications operate under standard computing that cannot deliver reliability. Downtime, planned or unplanned, hinders productivity and increases operating risks. Pipeline safety and performance are key operation goals for midstream oil and gas companies. With vast networks, real-time data and information are essential in maintaining safe operation of mission-critical applications.

- Operational technology (OT) and IT responsibilities converge. As a more limited, remote workforce becomes the new normal, operating technicians will shoulder more responsibilities in supporting field devices, such as SCADA (supervisory control and data acquisition), DCS (distributed control system) and PLCs (programmable logic controllers). They will need the ability to maintain IT/data infrastructures without IT assistance.

- Security of data and asset operations is a growing concern. Preventing cyberattacks is a major priority for pipeline operations. As more IIoT devices are installed to monitor equipment, protecting the flow of information and control is crucial. Pipeline operations require a distributed computing platform that secures access to all users in the supply chain while protecting data.

Simple – Redundant types of equipment and functions are used in pipeline and terminal operations. All are capital investments with operating and maintenance costs.

In designing the digitalization/edge-computing projects, engineers must carefully consider the total lifecycle costs of the devices and software. New advancements in software and hardware are occurring at an increasing rate.

Future-proofing the design ensures the flexibility to deploy software patches and updates quickly and efficiently. For pipeline applications, deploying easy-to-commission updates remotely and across several sites is a huge value consideration.

Autonomous – Midstream operations and assets are located thousands of miles apart. Edge architectures must be reliable and rugged to operate in various open environments. “Zero-touch” technology is needed to monitor and control remote assets; on-site personnel is not always available. The critical edge-computing platform must be self-monitoring and self-healing should problems occur.

Protected – As more machinery and equipment are connected in the field, security and cyberattack prevention are major criteria. The supporting edge-computing platform should incorporate redundant architecture to minimize any interruption by a single point of failure. Lost or unavailable data hinder decision-making.

Real-time notification of conditions unfolding in the field, such as power supply interruptions, pipe integrity failures, and critical equipment failures or unavailability, can be the difference between a slight setback or a full product release/leak/HSE accident.

References:

1 Kitani, K, “The $900-billion Reason GE, Ford and P&G Failed at Digital Transformation,” cnbc.com, Oct. 30, 2019.

2 Bittman, T., et. al, “How to Overcome Four Major Challenges in Edge Computing,” Nov. 4, 2019, Gartner.com.

3 Allemand, C., “Edge Computing is Key for Post-COVID Growth—And What Other Industries Can Learn about Resilience and Recovery from Oil and Gas,” Jan. 19, 2021, Stratus.com.

4 Allemand, C. “Benefits of Predictive Maintenance in Oil and Gas with Edge Computing,” Aug.10, 2020, Stratus.com.

Suggested reading:

“Deploy Edge Computing to accelerate digital transformation in midstream oil & gas,” Stratus.com.

“Managing pipelines of the future through digitalization,” Stratus.com.

Midstream and IIoT

The midstream oil and gas industry is on the digital transformation path. Oil and gas companies are investigating innovative technologies and solutions for many reasons, including the following:

- COVID-19 has accelerated the imperative drive for digital transformation and shifted investment away from other strategic initiatives.

- Because of safety protocols, the midstream industry is challenged to monitor and control decentralized, stranded assets and infrastructure using fewer technicians.

- Midstream companies must maintain operational resilience and performance with reduced resources.

- Balancing CapEx and OpEx, midstream companies must invest in solutions that efficiently deliver resilient operations and deliver value-producing, cost-saving opportunities.

- Edge computing is a key solution for pipeline optimization and operational excellence that solves short-term challenges from COVID-19, delivers fast payback and provides a foundation for long-term value.

Comments