September 2020, Vol. 247, No. 9

Permian Update

Proper Prepping Promotes Greater Profits in the Permian

By Ben Shuck, Manager-Technical Services, Weir Oil & Gas

As the oil and gas industry recovers from the COVID-19 pandemic, the ability for service companies to be responsive and nimble is vital. This requires that equipment is ready when service companies are, as deadlines can be tighter than ever. Proper maintenance is a must, and a true partnership between service companies and service providers underpins their success.

Carefully managing capital and maintenance expenses can significantly improve the bottom line. For service companies that parked pumps in earlier months, properly idling that equipment is essential to avoid damaging it and unintentionally increasing costs when it’s time to bring those pumps back into the field.

Service companies can’t afford significant nonproductive time (NPT) such as losses in pumping time or unplanned repairs from improperly stored pumps, especially now. Having a reliable partnership with a service provider helps ensure the life of equipment and its components.

Partnering with a service provider that understands your equipment needs isn’t only necessary when idling pumps, however. It’s beneficial in all sectors and economic conditions, because it gives service companies a competitive advantage that can help win contracts.

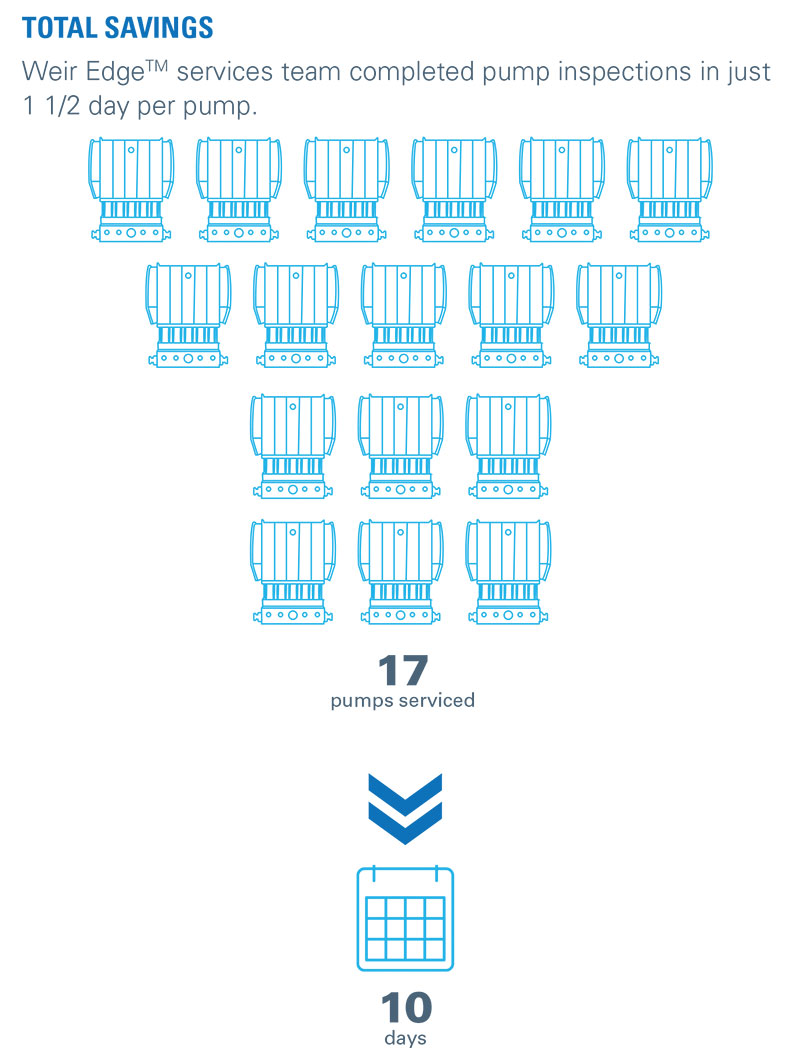

An integrated oil and gas field service provider experienced this firsthand in the Permian recently. The service company had a very tight time frame to begin a new frac job in the Permian Basin and needed 17 frac pumps on-site and ready to pump at more than 12,000 psi (827 bar) with zero NPT, otherwise the service company would lose that job and the potential for future work. All 17 pumps required inspections and replacement of all wear components so they could be sent to the job site within two weeks – a process that would normally take at least 30 days.

As a technical service manager, my field engineering team and I are very aware that our ability to respond can directly impact a service company’s ability to deliver to their customers. That’s why our support teams are positioned within three hours of every North American basin. Engineers and technicians from three service locations convened at the Weir Midland service center to inspect and service the 17 pumps, so the service company could meet its deadline with the confidence its pumps were ready for the high-pressure, high-rate job.

Service technicians conducted a 13-point pump inspection on each piece of equipment, replaced necessary wear items, inspected each pump’s lubrication system and reported required maintenance actions to the service company. A yard test was conducted for each pump to confirm its performance.

Servicing was completed in just 1½ days per pump – a process that typically takes three times longer. By responding quickly with an “all-hands-on-deck” approach, all 17 of the service company’s pumps returned to service within 10 days, without shortcutting the process or sacrificing quality. The service company started its Permian project on time with no unexpected downtime.

This example from the field demonstrates why it’s so important for service companies to partner with their service providers. They not only need providers who can properly service their equipment, but they need partners who can help them carve out a competitive advantage by meeting the demands of their customers.

As service companies seek to align themselves with service providers to ensure their ability to respond to contract opportunities, they should consider the following:

- Does the service provider have the engineering expertise to address equipment issues at the root cause so issues don’t reoccur and cause unplanned downtime?

- What’s the skill level of the service provider’s technical team(s)?

- What’s the proximity of the service provider’s teams to the basin where the job is located?

- Does the service provider address equipment issues in the context of the entire frac site?

- What tools does the service provider offer to empower maintenance crews to work better?

- How responsive is the service provider?

Today, service companies need service providers they can count on to help keep them competitive. Partnering with a service provider that can help ensure service companies are ready for the next job, no matter where it may be and what demands it may place on equipment, is a wise move as the oil and gas industry continues to evolve and emerge post-pandemic.

Author: Ben Shuck is technical service manager for Weir Oil & Gas in Fort Worth, Texas, overseeing the technical services team. He joined Weir in 2007, serving in its manufacturing engineering and design and R&D engineering teams before moving into technical services. He holds a Bachelor of Science degree in manufacturing engineering and a master’s degree in quality and engineering management, both from Tarleton State University.

Comments