July 2020, Vol. 247, No. 7

Features

Options for Low-Pressure System Now Requiring Overpressure Protection

By John Kopecky, Pietro Fiorentini USA

In the United States, 500,000 miles (805,000 km) of cast iron, ductile iron and copper gas main and service lines remain. Most of these older lines are in the Northeast and Midwest, yet even California and Alaska still have more than 1,000 miles (1,600 km) of these antiquated gas lines in their gas distribution systems.

Events over the last several years have proven the inherent risks that can be present in these older low-pressure systems. As a result, the National Transportation Safety Board (NTSB) has investigated the problems and made several recommendations.

In September 2019, in conjunction with NTSB, the Pipeline Hazardous Material Safety Administration (PHMSA) outlined several recommendations for the gas industry.

One of the most important recommendations was to revise Title 49 of the Code of Federal Regulations (CFR), Part 192, to require overpressure protection for low-pressure natural gas distribution systems that cannot be defeated by a single operator error or equipment failure. What does this mean for our industry? Following are several options that gas companies can use to meet these requirements.

Option A: Safety Relief Valve

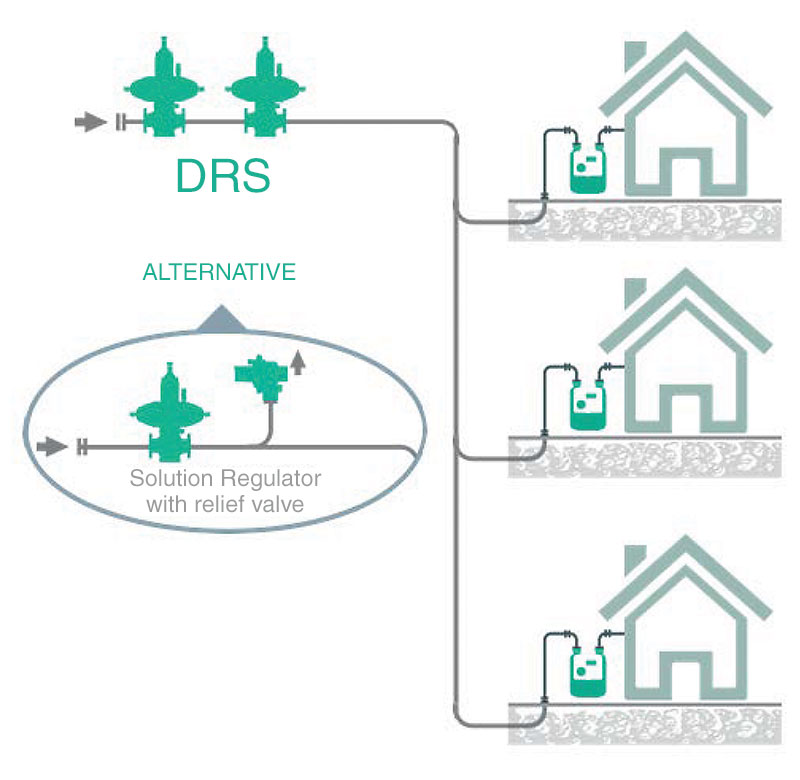

One option is to add a secondary overpressure protection with a safety relief valve with full relief to the existing district regulating system (DRS).

This option is very sensitive to the physical location where it is installed. In a densely populated urban area where a DRS is located in a vault or a pit, it may be quite challenging to install a relief valve.

Adding the safety relief valve may be an option with the lowest initial cost, but it does not come without other costs, both financial and environmental.

Full relief valves result in exactly that, full relief of the gas lines. This means that operators will be relieving large quantities of methane into the atmosphere and, while current natural gas costs are low, there is a definite financial cost to releasing large amounts of our product into the environment never again to be captured.

Option B: Safety Shutoff Valve

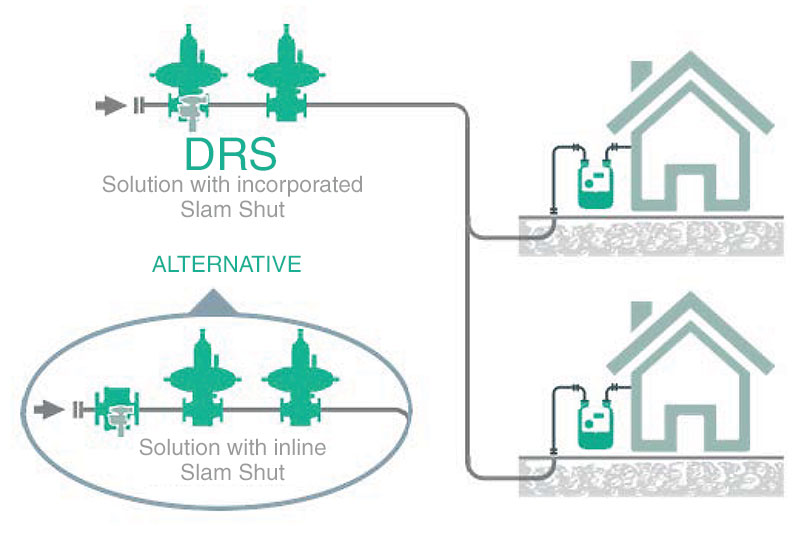

A second option is to add secondary overpressure protection using a slam-shut valve (SSV). When in conjunction with a worker-monitor regulator setup at the DRS, the SSV will stop the flow of gas when these two regulators have failed. Typically, if there has been a dual failure of regulators, the operators will want to shut off the flow of gas. It is typically a first responder’s initial action when encountering a failed system. In this case, the SSV has already stopped the flow of gas.

If the monitor regulator has the capability to have a built-in SSV option, the upgrade in usually a minor job with minimal capital investment. Another option is to add an inline SSV upstream of the monitor, yet this would require piping modification.

Having an SSV as a secondary overpressure protection system has additional benefits. Not only do most SSVs in the market have overpressure shutoff (OPSO) but the SSVs also can be equipped with underpressure shutoff (UPSO). The UPSO is a key feature to stop the gas supply in the event of a major rupture of downstream gas pipe – a definite risk that is present during digging operations.

When the distribution system is planned to be upgraded to medium pressure (usually when replacing with polyethylene pipe), the SSV solution sometimes can be upgraded to new operating conditions. This will require some modifications that usually can be accomplished by changing a setting spring or pressure switch.

Option C: Regulator Protection

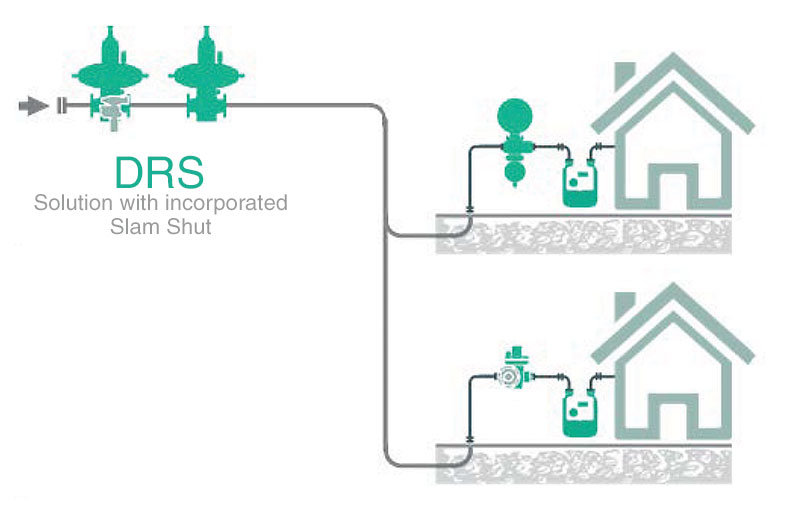

Adding a secondary overpressure protection on the house or commercial meter set using a regulator with an SSV is a third option. Advantages of this are shutting off the flow of gas only after the home’s or building’s regulator has failed.

Most likely after a double failure, the operator would want to shut off the gas flow. The standard checklist for a service technician responding would be to shut off the flow of gas while diagnosing the problems. Like in Option B, having an SSV serves as an OPSO, but some can also work as an UPSO. This can stop the flow of gas in an excess flow condition.

In buildings that have a SCADA system with a gas control room, the SSV can be provided with a limit switch to alert the gas control of the tripped SSV and improve the response time of emergency crews.

If there are plans to upgrade the existing system to medium pressure, the SSV system can likely be modified to the new operating conditions, similar to the SSV changes in Option B.

Option D: Slam-Shut Valve

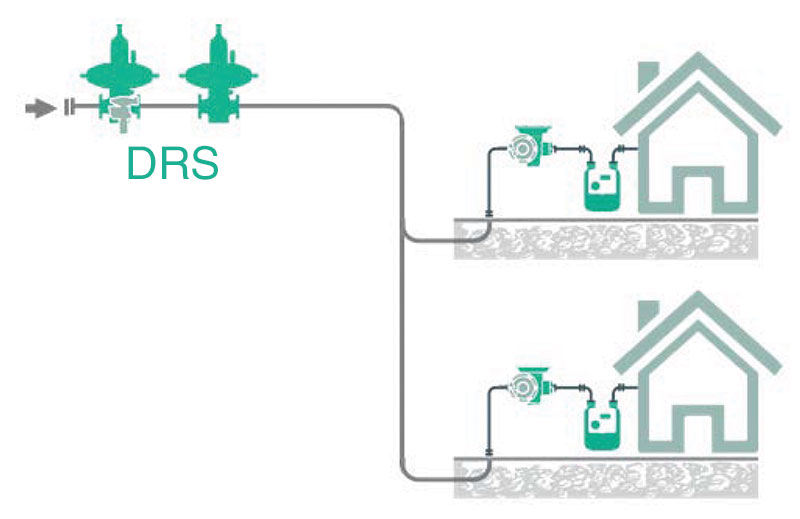

A final option is to add an overpressure protection system using an SSV to the existing house or building meter set that is protecting the home or business. As discussed previously, the SSV will stop the flow of gas after both the work and monitor upstream have failed.

After this failure, the rising gas pressures would trip the downstream SSVs and stop the flow of gas into each building equipped with the devices.

This provides increased safety at each customer location and can serve as not only overpressure protection but also underpressure protection.

One disadvantage of a stand-alone SSV is that it likely cannot be upgraded at a later date if the gas distribution system is upgraded to medium pressure.

For larger customers, the SSV can be provided with electrical proving limit switches to communicate with a control room.

What to Do?

It is clear that changes to our industry are coming quickly. We have seen the results of lack of certainty about the safety devices on low-pressure systems, and the new regulations will drastically increase the safety of our distribution networks.

The options above are worth considering to determine best what fits in the networks in your community.

Comments