February 2020, Vol. 247, No. 2

Features

New Approach to SCADA for Modern Pipeline Operations

By Russel Treat, CEO and Founder, EnerSys Corporation

The oil and gas supervisory control and data acquisition (SCADA) market is expected to grow over the next five years because of increased demand for the remote management of pipelines and growing pipeline networks. The question is: What approach should your operation take when setting up your SCADA system?

As we enter a new decade, mid-sized pipeline operators and emerging midstream companies have a unique challenge related to the implementation of SCADA. How do most effectively implement SCADA to support operations?

Historically, the approach has been to hire a SCADA manager who oversees the selection and acquisition of a SCADA platform. Then, the SCADA manager hires technical staff and may engage contract integrators to implement the pipeline SCADA system, including the pipeline human-machine interface (HMI). The SCADA manager also coordinates with IT as required for the hardware and network portions of building the SCADA system.

This historical approach may have been the best-available option in the past, but this “build a team, build a system” approach can become quite costly for pipeline operators. Thanks to advances in technology and new approaches from the vendors, operators have a new option to implement off-the-shelf SCADA toolkits that support the specific needs of pipeline operations, allowing operators to implement their pipeline HMI at a fraction of the cost and time of the historical approach.

SCADA vs. Toolkits

SCADA platforms have a set of capabilities that allow them to be used by any industry needing to monitor and control geographically dispersed assets such as oil and gas pipelines, water, wastewater, irrigation and traffic control, to name a few. A SCADA platform requires development for the platform to become a tool useful in a pipelining context.

Comparatively, a pipeline SCADA toolkit is the result of development efforts applied to a SCADA platform. In the case of regulated pipelines, this includes the creation of features and graphics to conform to the regulatory requirements of control room management. Specifically, the implementation of API RP 1165 (Recommended Practice for Pipeline SCADA Displays).

The traditional method of creating a SCADA system is to first select the software platform, then hire a team to build the system. However, most operators are staffed to operate and maintain, rather than to develop applications. As a result, many operators reach out to system integrators for assistance in executing a project.

While this approach allows a pipeline operator to create an application specific to their needs, it can place a tremendous strain on an operator’s technical resources and can represent significant execution risk.

For example, each stakeholder in the operation needs access to data to support their unique requirements. Requests for data and the demand for timely data can slow down the SCADA system, which creates inefficiencies, added costs and potential safety issues.

This traditional method of creating a pipeline SCADA system can be particularly challenging for the smaller operator or for the startup greenfield operator. The cost of hiring a SCADA manager, creating a team, engaging multiple system integrators, and straining IT resources can present significant challenges.

Consider the fact that any pipeline SCADA system must address each of the following elements:

- Points of integration: field automation, leak detection, measurement and scheduling

- Common features: compliance to control room management, conformance to API RP 1165, graphic elements for monitoring and control, and alarm presentation and processing

- Common users: pipeline control, field operations, measurement and scheduling

Fortunately for operators, though, about 80% of the features in a pipeline SCADA system are common across all operators.

The commonality of features – combined with advances in technology – creates the opportunity for a new approach to pipeline SCADA. The solution for operators is leveraging a lean and nimble approach to implementation through a feature-rich, mature pipeline SCADA toolkit without the development cost and risk.

Off-the-shelf SCADA toolkits include all of the standard features and required points of integration, leaving only configuration to the specific pipeline operator’s needs. This approach provides a rugged, reliable, easily configurable toolkit that is simple to maintain. The benefit for operators and midstream companies is the ability to minimize development costs and lead time.

Groups Benefiting

For an off-the-shelf SCADA toolkit to be viable, a complete set of pipeline features and capabilities should be included in the application to ensure that development is complete, mature and feature-rich.

Control Room

One of the most important uses of pipeline SCADA applications is to support the control room by providing displays for maintaining situational awareness, system monitoring and control. Further, the control room needs tools to perform normal operations such as startups, shutdowns and alarm response.

The goal is that the pipeline HMI displays facilitate the ability for the pipeline controller to maintain situational awareness, while having an enhanced ability to identify abnormal operations and to respond effectively.

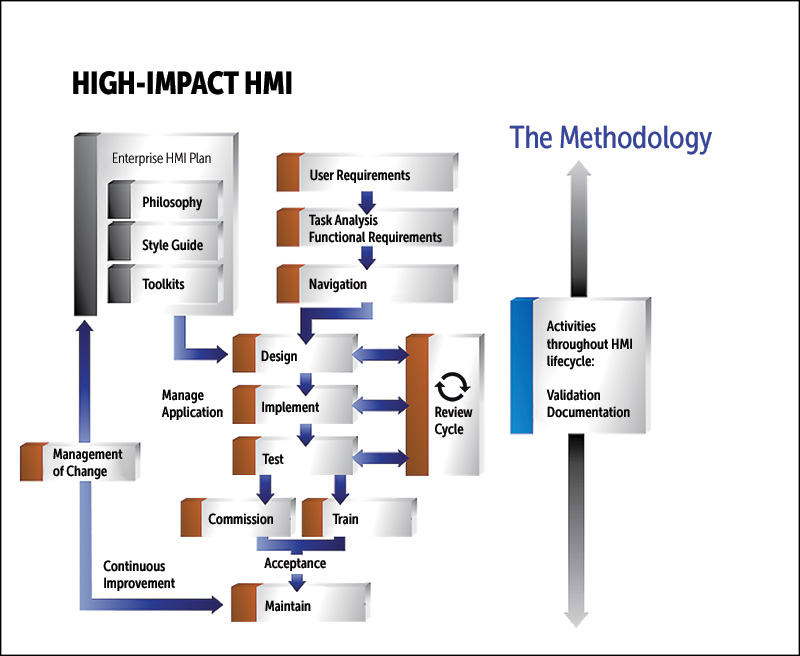

By acquiring off-the-shelf standardized graphic elements, animations and pipeline-specific system behaviors, the pipeline operator streamlines their ability to implement high-performance HMI at the lowest possible cost – with consistency.

SCADA HMI Displays

Typically, the SCADA team’s primary focus is the addition, removal and troubleshooting of communication to field devices and the related HMI displays. Frequently, issues such as regulatory compliance, conformance to the most recent standards and improvements in the graphic elements and animations take a lesser priority. That will change in 2020 due to the anticipated update to API RP 1165 this year.

The first edition of API RP 1165 was issued in January 2007. Much about computer displays and their capabilities has changed in the last 13 years, which is why the industry is focused on modernizing this recommended practice to reflect current technology.

The update to API RP 1165 is also focused on advancing HMI displays to better equip pipeline controllers to perform their work while maintaining situational awareness. Operators adopting the new API RP 1165 will be encouraged to provide more contextualized information that creates a deeper level of understanding. This is typically accomplished through advanced graphic displays. While the details of displays are unique to each pipeline operator, the graphics and animation should pre-exist in the application to meet the graphic element requirements outlined in API RP 1165.

Measurement

Measurement personnel need access to real-time measurement data from the field to verify the authenticity of the measurements and validate the measurements for the back office. However, the measurement group is a secondary user of SCADA, and as such, this sometimes can go unaddressed.

An off-the-shelf toolkit that includes measurement functionality enables the measurement team to perform critical tasks such as collecting and validating data points, scheduled collection of electronic flow measurement (EFM) audit data, time synchronization and gas quality updates.

In this setup, the daily management of measurement is simplified to provide accurate, timely data for operational decisions and measurement management.

Communications

Critical to the operation of any SCADA system is the communications infrastructure, which includes field data communications and network infrastructure.

An off-the-shelf toolkit includes components for both communications monitoring and alarming. Additionally, displays should be made available to both the control room and to the support personnel responsible for maintaining effective communications.

IT Management

Pipeline SCADA toolkits are easier for the IT team to maintain, update and manage. For example, when the revised API RP 1165 is released, the IT team can accept updates from the off-the-shelf vendor rather than taking away resources from ongoing maintenance and management.

Broadening out the technological benefits of pipeline SCADA applications, the IT team is empowered to configure the software to align with available resources in the operation.

IT supervisors and teams that desire a simplified setup to better manage resources – such as the need for increased support during peak operating periods – have the opportunity to manage resources in real time, to support additional data requests.

Another important factor is the role of cybersecurity in pipeline SCADA toolkits. Because the software can be installed to match available resources and the preferred configuration, the IT team can set up proper security protocols and processes to protect the data in the SCADA software. This enables the IT team to reduce the risk of a data breach or other cybersecurity event through enhanced maintenance, updates and management.

Additionally, an off-the-shelf provider helps ensure that pipeline SCADA applications stay current with regulatory requirements, standards updates and technology.

Overall Benefits

The update to API RP 1165 will usher in a new, modern era of pipeline SCADA HMI. Small-to-medium operators and emerging midstream companies have the opportunity to get out ahead of the industry by implementing pipeline SCADA toolkits in 2020 to address each critical need of pipeline operations.

Operators and companies that use this new software approach will realize benefits such as improved efficiency, natural compliance, operations safety and a reduction in total cost of ownership for their SCADA technology investment.

Our company, EnerSys Corporation, is working with operators and companies to utilize the latest technology and tap into current software capabilities to build a modern SCADA system. Operators and companies no longer need to rely on bulky SCADA platforms that pull too many resources, create an IT burden and present risks to operational integrity. There is a much more reliable, nimble and achievable option through off-the-shelf pipeline SCADA toolkits.

Author: Russel Treat is the CEO of EnerSys Corporation, a provider of control room management and SCADA software for pipeline operators.

Comments