February 2019, Vol. 246, No. 2

Features

Advanced Analytics Can Help Boost Pipeline Performance

By Jacques van Dijk, Director, Midstream Industry Solutions, Aveva

Oil prices have swung sharply in recent months, fluctuating between $40/bbl to a high of $85/bbl Brent. The unexpected price volatility is causing stress on the capex and opex of the oil and gas value chain.

Compounding the challenges, the negative perception of fossil fuels, rising trade tensions and geopolitical upheaval are all adversely affecting near-term demand and business costs. As a result, more companies are looking to squeeze their assets. The term “digital transformation” is heard more often as one of the means to achieve lower costs and reduce risks.

Midstream oil and gas pipeline companies have been collecting huge amounts of operational data – from supervisory control and data acquisition (SCADA) to pipeline applications, to enterprise resource planning (ERP) systems and others, long before the industrial internet of things (IIoT) was coined.

However, turning vast amounts of raw data into contextual information around equipment and processes was not an operational imperative, indeed many companies did not fully realize the non-operational value of their data.

Currently, only between 2% and 10% is being processed and analyzed. This means companies are still often missing opportunities to capture operational insights and business value. Leveraging existing operational data as well as new data sources available as part of a digital transformation, if well executed, will provide great opportunities for companies to significantly improve performance through better asset reliability, efficiency and safety performance.

Power of Analytics

With advancements in technology – cloud, analytics and computing power, companies can now quickly analyze data to effectively optimize their process and assets. The power of analytics means that companies can use advanced pattern recognition, statistical models and machine learning technology to model an asset’s operating profile and processes, and predict future performance, recommending appropriate, timely actions to improve uptime of pipeline throughput and to optimise operating conditions.

Analytics can be used across the entire pipeline operations from asset to process, through to operational control. They can be applied to multiple assets to provide insights based on a system view not only to better predict failure of processes and equipment, but also to act as a process validation layer. For example, data from gas chromatographs and odorizers, when combined with a network data model and a model of gas quality distribution, can be used to determine whether odorization is working as planned.

Data is being leveraged for process and operational analysis purposes, but the use of data for asset analytics provides the most gains in operational safety, reliability and profitability through improved asset reliability.

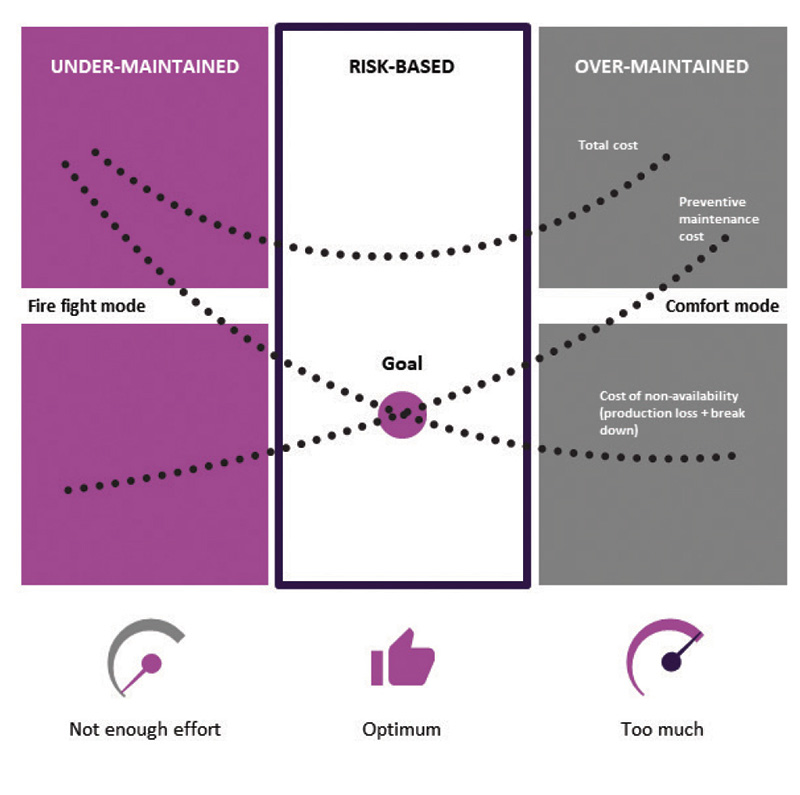

Midstream oil and gas pipeline companies employ different maintenance strategies. Some accept the loss in production and the cost of a corrective maintenance (run-until-fail) approach. Others invest in regular and costly periodic (preventive) maintenance.

An optimal maintenance strategy combines different approaches for different assets based on the cost of failure of the type of asset. A proactive approach to maintenance, known as condition-based maintenance (CBM), can be used to define the operating boundaries of an asset before an alarm is raised.

Predictive asset analytics, a step-up from CBM, enables modeling of, for example, rotating equipment performance using advanced pattern recognition and machine learning algorithms to identify and diagnose any potential operating issues, days or weeks before failures occur. Having early indications of failure enables parts to be ordered and maintenance to be scheduled at an opportune time in pipeline operations, instead of reactively needing to shut down the pipeline.

By analyzing different assets within a pipeline network, companies can create a risk-based maintenance strategy, in which the appropriate analytics can be used for specific assets. A risk-based maintenance approach balances the extremes of costly preventative and reactive maintenance by using a combination of predictive asset analytics and condition-based maintenance. Typical use cases in midstream operations include pumps and compressors, ultrasonic meters, valves, pressure regulators and odorizers.

Process Analytics

Analysis of data from multiple assets (as well as other sources) can be used for process improvement. Simulation models of flow process can identify pipeline leakages, anomaly/pig tracking and product/transmix tracking. Some of the areas where process analytics can be leveraged include:

Integrity management: Analysis of data from cathodic protection equipment, corrosion monitoring and inline inspections can provide early warning of potential pipeline failures such as leaks and ruptures. Combining the data with external inspections provides additional metrics for more accurate predictions, thereby improving the integrity management process.

For leak detection, a combination of a high-fidelity simulation model and machine learning can be used to improve leak detection outcomes. For example, thresholds for declaring a leak based on a volume imbalance between simulated and real-time data can be tuned based on historical data analytics.

Measurement data: Analysis of measurement data can be used to identify any anomaly leading to equipment issues. For example, a meter continuously provides the same data can indicate equipment failure and can be flagged earlier to minimize accounting loss. As an accurate assessment of gas quality is a vital part of gas measurement, ensuring chromatographs function correctly is extremely important, too.

Alarm analytics: API 1167 11 suggests several key performance indicators (KPIs) which are helpful to garner insights into alarms and related information such as average and peak rates for alarm rates per controller position, alarm floods, frequently occurring alarms, chattering or fleeting alarms, stale alarms, alarm suppression and alarm attributes (configuration). These KPIs are helpful in managing alarms and reducing the load on operators, but more useful contexts can be obtained through analysis of the alarms and alarm configuration; analysing values for tags with frequently occurring chattering or fleeting alarms can be used to establish alarm limit changes, reducing the number of alarms or events without impacting the process. This allows more efficient handling of the operational process without compromising safety.

Operational Control Analytics: Using analytics to perform real-time analysis of data can support informed decision-making for operators. As operations models improve over time, more and more patterns of control will emerge to aid autonomous operations. Examples of operational control analytics include:

Normative value analysis: To improve operations, companies have started to look at “normal” values or placing operator alert limits on tags based on the operating modes. This allows operators to be made aware of abnormal situations that are well within the operational limits but are not in keeping with previous instances of the same operational mode.

Future operational analytics: Elements or building blocks of autonomous control – this is the functionality to perform sequence of actions based on pre-defined trigger conditions – are starting to be used more widely. This includes the ability to perform automatic shutdowns based on unsafe conditions.

Through analytics, expert systems and artificial intelligence, system operation will become more automated from scheduling through to delivery of the product. Ultimately, it is a journey to continuous improvement beginning with better data and context for operator decision-making, followed by recommendations and what-if scenarios, gradually progressing to automated control during normal operations and finally in abnormal situations.

Conclusion

Analytics for midstream is not just hype. Real-world use cases have demonstrated that leveraging advanced analytics for assets, processes and operational control enables pipeline companies to maximize return on assets and improve operational efficiencies. P&GJ

Author: Jacques van Dijk is director of the Midstream Industry Solutions group at Aveva. He holds a bachelor’s degree in computer science and applied mathematics and a master’s degree in computer science from the University of Cape Town (South Africa). He is a certified project management professional (PMP) and has 15 years of oil and gas pipeline industry experience.

Comments