January 2018, Vol. 245, No. 1

Features

Microfluidics Probe ‘Cholesterol’ of Oil Industry

It sounds cliché, but things do get worse before they get better when oil and gas lines are being cleared of contaminants, according to Rice University researchers. Until now, nobody knew exactly why.

Asphaltene is a complex of hydrocarbon molecules found in crude oil. It is the source of valuable asphalt and can also be made into waterproofing and roofing materials, corrosion inhibitors and other products, but when it builds up in a pipeline, it’s trouble. Asphaltenes are often called the “cholesterol” of the oil industry since they are known to coagulate and slow or even stop the flow of oil and gas in reservoir rock.

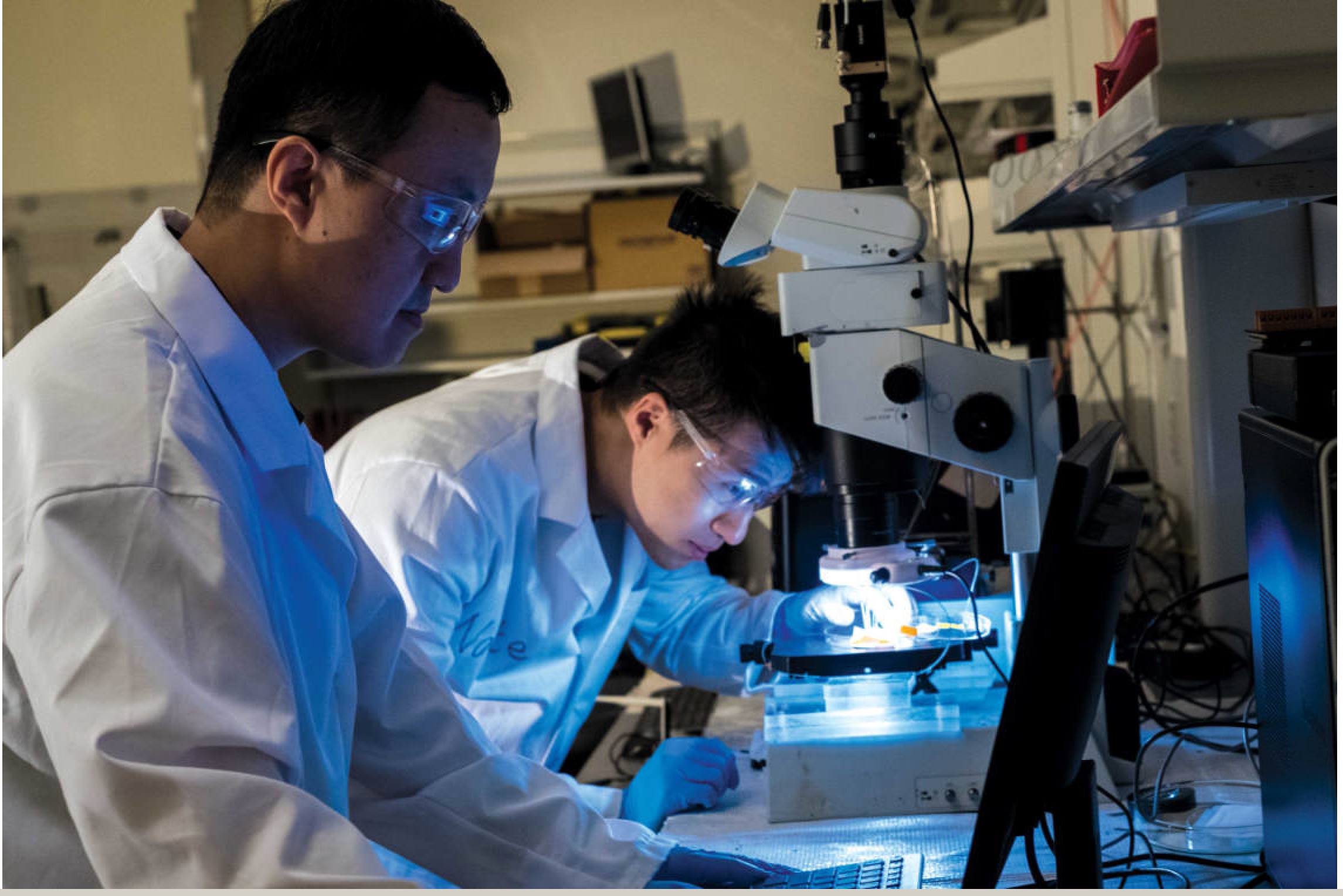

Rice engineer Sibani Lisa Biswal and her colleagues used their unique microfluidic devices, instruments that use a small amount of fluid on a microchip to perform a test, to examine four commercial chemical dispersants that curtail the buildup of asphaltene in wells and pipelines. The devices allowed them to watch how the dispersants react with asphaltenes.

Ensuring flow through pipelines is paramount in oil and gas production, so advances that help keep lines clear are important to the industry. To date, chemical companies have generally performed static bulk tests on anti-asphaltene products, Biswal said.

The Rice lab makes microfluidic devices with microscopic channels through which researchers can watch the dynamics of asphaltene deposition in real time, with or without dispersants and at a variety of flow rates.

“Everything in our system is transparent,” Biswal said. “Crude oil hasn’t been very compatible with the microfluidic devices others are using (because the channels and pillars are too wide), and the type of devices we’re making have only been possible with recent materials. We’re one of the early groups to push the idea that we can use these systems to visualize oil flow processes.”

The devices allow oil to flow around pillars that are only 125-microns wide and leave channels that are roughly the size of those in oil-bearing formations. Through a microscope, Biswal and lead author and Rice graduate student Yu-Jiun Lin watched as asphaltene formed delta-shaped clumps in front of and behind the pillars, eventually filling in the channels.

When chemical dispersants were added to the crude, the researchers saw something they didn’t expect: The deposits appeared even sooner, but then began to break down and fall away in the flow.

Dispersants are designed to make asphaltene particles smaller, and the experiments proved they do. “The idea is, if you make the crude oil nanoparticles smaller, it’s less likely that they’re going to be able to deposit inside a pipeline or plug porous media,” Biswal said.

“But almost all tests up to now have been done on a bulk scale and very few under flowing conditions. Companies were just seeing if their chemicals make particles smaller. And they do. What they didn’t understand is that the smaller the particle is, the less likely it’s going to follow the fluid stream. In the presence of dispersants, deposits can actually get worse.”

The saving grace, she said, is that dispersants appear to chemically alter asphaltene by increasing repulsion between the aggregates. That makes it more difficult for particles to stick together. “We refer to them as softer asphaltenes,” Biswal said. “It doesn’t take much force to break up large aggregates.”

Lin said dispersant manufacturers typically use liters of crude oil in each test. “We just need a milliliter of crude, and we get better resolution than they do,” he said. “When the asphaltene content is very low, traditional methods fail to see a difference in chemicals, or even a deposit.”

Co-authors of the paper are postdoctoral researcher Peng He, lecturer Mohammad Tavakkoli and Francisco Vargas, an assistant professor of chemical and biomolecular engineering, all from Rice; Nevin Thunduvila Mathew, Yap Yit Fatt and Afshin Goharzadeh of the Petroleum Institute, Abu Dhabi, United Arab Emirates; and John Chai, a professor of engineering and technology at the University of Huddersfield, United Kingdom. Biswal is an associate professor of chemical and biomolecular engineering and of materials science and nano-engineering.

The Abu Dhabi National Oil Co., the Abu Dhabi Oil research and development subcommittee and the Petroleum Institute supported the research.

Comments