January 2015, Vol. 242, No. 1

Features

Cold Weather Can Play Havoc On Natural Gas Systems

Cold weather can produce threats to the integrity of distribution pipeline systems. Integrity management (IM) concepts required an operator to identify threats as a necessary step to prioritizing integrity assessments and developing mitigations.

This article discusses the most common threats to natural gas distribution systems caused by cold weather and identifies the attributes of the most susceptible systems, reported from 1984 through mid-2014. This information enables gas distribution system operators to contemplate preventive and mitigating measures to address cold weather risks in the context of distribution IM programs.

The effects of cold weather on pipeline systems are typically classified as time-independent (randomly occurring) threats. Failure due to a random threat is an event-driven, such as dig-ins, rather than time-dependent threat – corrosion, for example.

With exposure to cold weather, the pipeline system can be threatened by a number of circumstances that can cause failure in components. Some of these include frost heave, loads on pipeline components due to snow and ice accumulation, thermal stresses due to extreme cold temperatures, and confined expansion of freezing water within components.

Causes Of Incidents

The Pipeline Hazardous Material Safety Administration (PHMSA) has collected failure data for natural gas distribution pipeline operations in the United States. The reports include categorized causes. The “natural force damage” category includes events such as landslides, lightning, heavy rains and severe weather conditions.

A key word search of the PHMSA gas distribution incident data revealed that some reported as caused by “equipment failure,” “other outside force,” “earth movement,” “temperature,” and “miscellaneous” were caused by cold weather effects as well.

The reporting interval for the data reviewed was 1984 through mid-year 2014. During that time there were 129 incidents associated with cold weather (Figure 1). Of these incidents, the frequently cited was frost heave, followed by failures due to snow or ice movement.

What Is Frost Heave?

Frost heave results from ice forming beneath the surface of soil during freezing conditions in the atmosphere. The ice grows in the direction of heat loss (vertically toward the surface), starting at the freezing front or boundary below the soil surface.

It requires an unfrozen water supply – usually below the frozen soil – to keep feeding the ice crystal growth. The growing ice is restrained by overlying soil, which applies a load that limits its vertical growth and promotes the formation of a lens-shaped body of ice within the soil. The growth of ice lenses continually consumes the rising water at the freezing front.

The soil through which water passes to feed the formation of ice lenses must be sufficiently porous to allow capillary action, but not so porous as to break capillary continuity. Such soil is referred to as “frost heave susceptible.” Two common criteria for susceptibility are more than 10% of soil particles being finer than 0.075 mm or more than 3% of particles being finer than 0.020 mm.

Considering particle size alone does not account for the effects of variables such as the presence of groundwater or dissolved salts that can alter the freezing state. A more comprehensive test would be needed for precise information about susceptibility. Visible vertical displacement of the ground surface or effects on pavement would be consistent with the occurrence of frost heave.

The primary structural integrity effect to pipeline systems as a result of frost heave is excessive longitudinal or bending stress due to the displacement strain imposed by the earth movement. The likelihood of a failure due to frost heave may be increased when other conditions exist, such as low-strength girth welds or threaded connections. The susceptibility of a pipeline system to damage by frost heave can be assessed by considering some key factors:

• The soil type in which the pipeline is laid. Silty and loamy types of soils may be susceptible to frost heave while clay, clean sand and gravel are not.

• The depth that a pipeline is buried. Lines buried below the frost line are less susceptible to the effect of frost heave since the earth movement typically occurs above the frost line.

• Pipeline materials or method of installation. The ability of a pipeline to withstand high longitudinal stress or strain may affect its likelihood for failure due to frost heave.

These factors indicate failure due to frost heave and the presence of other conditions, perhaps related to how the pipeline was installed, could represent probable interacting threat circumstances.

Interacting threats are understood to occur if the probability of failure due to coinciding factors is significantly greater than the sum of individual probability of failure from the factors occurring independently. Frost heave or snow loads, while not desirable, may be readily tolerated by ductile materials and high-strength joints between pipes.

Likewise, low-ductility materials or vintage pipe construction technology (acetylene welds, threads), while not optimal, may not pose a risk if normal internal pressure is the only significant load. However, certain combinations of materials in conjunction with cold weather effects can create a greater likelihood of failure than either set of circumstances do separately.

Weather Failure Data

Analysis of PHMSA-reported incident data provides additional insight to the types of distribution systems that may be vulnerable to cold weather effects. The data was evaluated in terms of installed location, era of installation, affected material, affected component, size of pipe and geographic location.

Installed location: A significant majority of the gas distribution incidents caused by cold weather, 74%, affected buried pipe or components. This is consistent with the predominant identified causes as related to frost heave or thaw settlement. A large proportion of those underground also occurred under pavement.

Era of installation: The reported incidents due to cold weather were fairly evenly distributed over 20-year segments of time representing different periods of installation, from 1910 to the present, except that the era from 1950-69 had about twice as many incidents as other eras.

It was thought that the larger number of incidents for 1950-69 vintages may reflect the large proportion of pipe in service installed during that time. In order to understand whether certain vintages of pipe have high or low susceptibility, the proportion of incidents attributed to specific decades of installation were compared to representative proportions of mains miles in service.

Disproportionately high susceptibility is indicated by a ratio of the proportion of incidents to the proportion of mains mileage being significantly greater than 1.0. Similarly, low susceptibility is indicated by that ratio being less than 1.0 (Figure 5).

Figure 2: Normalized susceptibility by installed decade.

The results show pipe installed earlier than 1950 has disproportionately high susceptibility to problems from cold weather. This is also true for pipe of unknown vintage.

The greater susceptibility of pre-1950 pipe is thought to be due to two key factors. One would be the generally inferior low-temperature ductility of the steels of the era. The other would be the methods used to join pipe, including early electric arc welds, acetylene welds, couplings and threaded collars, all of which could have strength or ductility properties that limit tolerance for loadings induced by frost heave or thermal contraction.

Post-1960 systems exhibited comparatively low susceptibility, owing to improvements in pipe product and girth weld quality. All post-1980 systems grouped together have a low normalized rate of 0.394.

Affected materials, components: Identified materials associated with the cold weather incidents were classified as steel, plastic, iron, other and unknown. The systems reporting the highest numbers of failures were constructed of steel and cast- or wrought-iron, representing 40% and 42% of the incidents, respectively. Plastic and other materials showed few instances, representing 7% and 8%, respectively.

The identification of materials may be confounded by the fact that non-pipe components may be of different material than the pipe material, and may not have been identifiable in the incident report.

However, the numbers of occurrences do not properly represent relative susceptibility. Iron and other or unknown materials comprise very small proportions of the total mains mileage in service. The ratio of the proportion of incidents normalized to the proportion of representative miles shows extremely high susceptibility for those materials, 14.2 and 21.6, respectively, compared to steel or plastic with normalized rates of 0.88 and 0.13, respectively.

A majority of reported cold weather incidents, 57%, occurred in mains pipe, while service risers were reported in 19% of the cases (Figure 3). Meters and regulators were associated with 19% of the failures reported with the most identified causes related to snow and ice accumulation or freezing affecting the components.

Figure 3: Cold Weather Incidents by Component.

Incidents by location: Incidents associated with cold weather not surprisingly are concentrated in northern areas, particularly the north-central and New England states (Figure 4).

However, such incidents have also occurred at lesser rates throughout the country, including regions which have warm climates. In fact, only 13 states have reported zero incidents over a 20-year period, some of them known for having severe winters (Arkansas, Maine, and South Dakota).

Certain states have the most occurrences of cold-weather incidents, notably Pennsylvania, Massachusetts, Maine, Iowa and Michigan. However, these rates reflect total exposure considering climate, system mileage, system age and make-up. When the occurrences are normalized by aggregate mains and services mileage by state, the location profiles change drastically.

Where the values exceed 1.0, the rates of occurrences within the state exceed that state’s proportion of total mileages. Vermont and Rhode Island are prominent, with Connecticut, Washington, DC, North Dakota, New Hampshire, Massachusetts and Wyoming also well above normal (Figure 5).

Figure 4: Rate of cold-weather incidents by location.

Figure 5: Rate of cold-weather incidents normalized by mileage

Causes, Consequences

A majority of the distribution systems in cold-weather areas cited natural forces or outside force damage, in many cases, frost heave. Other less often cited problems included:

• meter damage from snow or ice shedding off rooftops, or from falling trees due to ice accumulation;

• thermal contraction stress;

• fractures due to expansion of moisture trapped inside components, and

• equipment or device malfunction due to icing.

There were also more complex failures, including a few incidents of environmental cracking, most likely near-neutral-pH stress-corrosion cracking in the threaded pipe ends of service lines. These involved stresses caused in part by frost heave or thaw settlement.

Only one such incident is identified in the PHMSA database as cold-weather-related, specifically frost-heave, and none are identified as having been affected by environmental cracking.

Also, there were a few incidents in which volumetric expansion of freezing water at the ground surface caused excessive reaction forces on branch connections or components.

These cases illustrate the potential complexities of integrity threats associated with cold weather, or even proving that cold weather was the cause. It is possible that cold-weather-related incidents are under-reported.

Some other types of incidents were cited but the cold weather was described as a secondary cause. Several involved vehicles skidding off icy roads and striking aboveground equipment, or dozers using rippers to break frozen soil striking pipes.

One could argue that if not for winter weather these incidents would not have occurred. However, these are clearly due to careless actions and might have occurred under other weather conditions, and were excluded from the analysis.

Another questionable category involved flooding induced by large snowmelts. These incidents were included because the temperature may have affected pipe properties, and ice build-up could have worsened the dynamic loading on the affected spans, compared with flooding in warm weather.

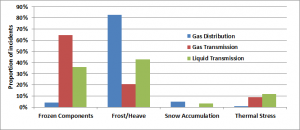

The data also showed the frequency of incidents involving frost heave is substantially higher in gas distribution systems than in gas or liquids transmissions service (Figure 6). This is likely due in large part to shallower depth of burial, prevalence of threaded or coupled joints, smaller diameter pipes and use of cast-iron pipe. Transmission systems, however, are substantially more vulnerable to incidents caused by freezing of pressure-control equipment and other devices.

Figure 6: Incidents by cause for gas distribution, gas transmission, and liquid transmission systems

Most incidents were reported as leaks, frequently as separations of couplings or threaded joints. The few incidents identified as ruptures are thought to have been erroneously reported. Of the 129 gas distribution system incidents from 1984 through mid-2014, the following consequences occurred: five incidents caused eight fatalities; 35 incidents caused 52 injury cases.

A majority of the cold-weather incidents caused fire or explosion. None of the cold-weather-related incidents reported for gas transmission pipelines or hazardous liquid transmission pipelines in the sample period caused fatalities or injuries. This underscores the risk factors associated with gas distribution systems, namely the prevalence of gas migration paths and proximity to buildings. Frozen soil conditions can worsen tendencies for subgrade migration.

Summary, Recommendations

By far the most common cause of cold-weather-related incidents in gas distribution systems is frost heave. However, other incident scenarios related to cold weather repeatedly described in PHMSA’s reportable incident database include icing of pressure and control equipment and damaged equipment caused by falling snow and ice loads. All types and vintages of pipe materials found in gas distribution service have been affected; however, the following pipe materials and components appear to have higher-than-average vulnerability:

• cast-iron pipe;

• pressure control equipment, including regulators, valves and switches that are poorly isolated from weather;

• steel pipe installed prior to 1950;

• pipe installed with threaded connections;

• pipe located above soils susceptible to frost heave, and

• risers and equipment located close to the ground in standing water.

IM principles require the operator to consider integrity threat interaction. Frost heave or snow load might be readily tolerated by some materials or a piping system in sound condition, while low-ductility materials or pipe joints made by vintage techniques may remain reliable, absent certain outside forces. However, when these conditions exist simultaneously, the likelihood of a failure is significantly greater.

Piping systems with higher-than-average vulnerability and located in areas susceptible to frost heave or thaw settlement should be identified and considered for condition monitoring or mitigation activities.

Other causes have also been identified, including snow and ice falls from rooftops onto pressure-control devices, confined freezing of water trapped in components, or buildup of ice where standing water accumulates around risers or under low-mounted aboveground components.

Condition monitoring could involve a range of activities, including but not limited to:

• periodic visual site inspection prior to cold-weather months by someone qualified to recognize evidence of frost heave or thaw settlement;

• examination of piping buried above the frost line for evidence of deflection at joints during opportunistic excavations for other work, and

• visual inspection of sites for frozen standing water around risers or under equipment mounted low to the ground.

Mitigations could include:

• replacement of cast-iron pipe and threaded steel pipe with plastic or welded steel pipe in locations known or suspected to be susceptible to frost heave;

• remediation of drainage or soil conditions that promote frost heave at susceptible sites;

• correction of drainage conditions that promote accumulation of standing water around risers or under low-mounted equipment;

• draining or blowing out trapped moisture from equipment during routine maintenance or inspections;

• cleaning external dirt and debris that may hold moisture and freeze, interfering with mechanical action from pressure-control equipment during routine examinations, and

• protection of equipment exposed to direct impact from snow or ice falls from buildings, or exposed to falling tree limbs due to ice storms.

Author: M.J. Rosenfeld is chief engineer with Kiefner/Applus-RTD and is involved in a variety of pipeline integrity projects. Rosenfeld is a member of ASME B31.8, is a PE in Ohio and is an ASME Fellow.

Comments