September 2013, Vol. 240 No. 9

Features

Barrier Seal Breakthrough Improves UK Gas Grid Compressor Reliability

Many countries rely on their natural gas grid almost as much as they do their electrical grid, which makes it socially as well as economically imperative for network operators to strive for the utmost in system reliability.

Centrifugal compressors are the beating heart of gas grids, assuring a consistent flow to industrial, commercial and residential customers, including gas-fired power stations, through peaks and troughs in demand. Compressor performance and availability, in turn, is closely related to the effectiveness of sophisticated compressor shaft sealing technology.

The shaft seal creates an impermeable barrier between the pressurized gas supply and unpressurized ambient environment, preventing pressure loss and contamination of the former and protecting the integrity of the compressor. If the seal performance degrades, the compressor is compromised.

Conventional sealing solutions have served gas producers and distributors well enough, but the quest for a further leap in reliability has led to development of a new type of seal that can deliver improved compressor availability in LNG liquefaction, transport and gas transmission or any oil and gas compressor application: the coaxial barrier seal CobaSeal.

This new sealing technology is the development EagleBurgmann, first installed in collaboration with gas network operator National Grid UK and compressor manufacturer Siemens Energy. Several months of field operations have confirmed the results of pre-launch testing: the CobaSeal is more robust than older seal types, consistently reliable in all operating conditions and provides cost savings in the form of reduced nitrogen gas consumption.

[inline:Compressor at Nether Kellet Booster Station]

Barrier Seal Protects Dry Gas Seal

National Grid operates Great Britain’s gas transmission system, comprising 7,600 km of high-pressure pipeline, including 24 compressor stations. Its Nether Kellet booster station near Manchester uses dual gas-turbine-driven Siemens STC-CP type centrifugal compressors with the overhung impeller design widely used in gas transmission.

The shaft-sealing technology used – a dry gas seal in tandem arrangement with a nitrogen-buffered carbon ring barrier seal – had been the industry standard until now. The dry gas seal performs the principal sealing function, while the carbon ring seal protects the dry gas seal against bearing oil contamination and guards against compressor gas contamination of the bearing brackets.

At Nether Kellet bearing oil leakage over the existing barrier seal was contaminating the dry gas seal, causing an undesirable level of unplanned compressor down time as well as a loss of nitrogen pressure during pressurized standstill periods. The loss of pressure resulting from the distortion of the carbon ring segments of the seals is linked to low-pressure cycling in the pipeline. Low-pressure cycling is part of normal pipeline operations and is unavoidable.

Wanted Contact-Free Operations In All Conditions

National Grid and Siemens Energy asked EagleBurgmann in 2010 to help develop a better solution. The customers envisioned a barrier seal design that would tolerate vibrations from high gas film stiffness and assure contact free operations in all operating modes. It would be sufficiently robust to eliminate the issue of broken sealing rings.

There would be no oil leakage during standstill or low roll operations, gas leakage prevention would be assured, and the new design would boast very low nitrogen purge gas consumption and fluctuation – reducing operating costs. Nitrogen (minimum -50°C) is used to ensure the carbon rings have sufficient sliding capability for the aerostatic barrier seal to achieve liftoff from the compressor shaft after stoppages.

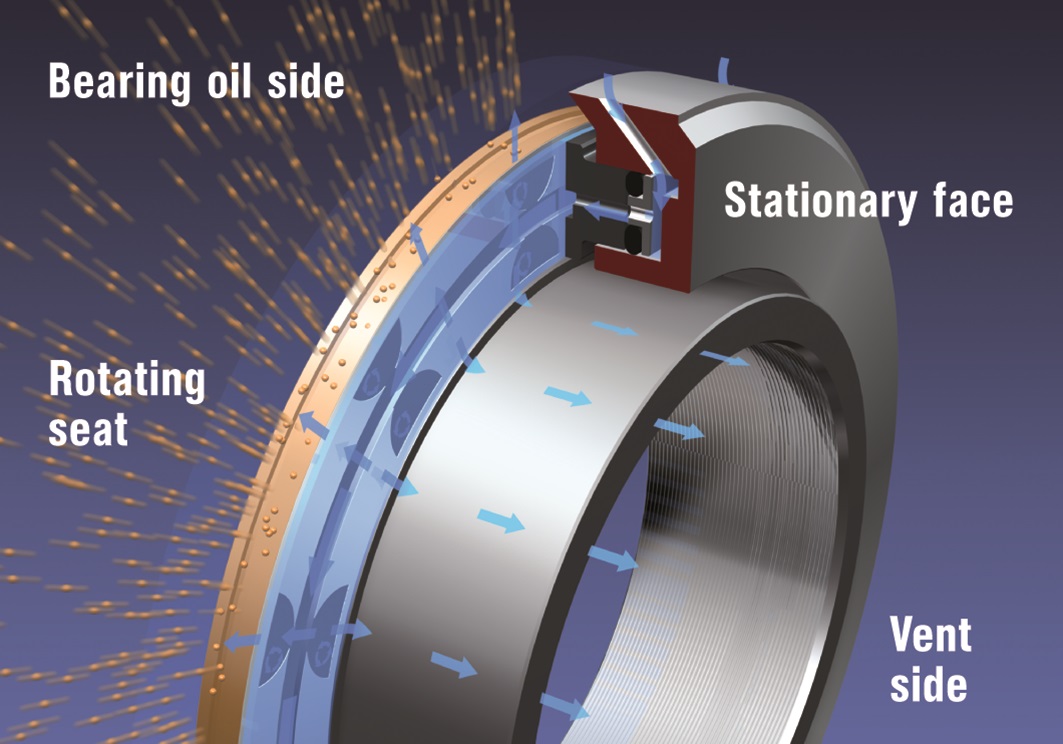

The solution: a conventional dry gas seal in tandem with the newly designed coaxial barrier type seal substituting for the existing carbon ring seal. The CobaSeal design, similar to that of a dry gas seal, is comprised of a rotating ring made of ductile material and a spring loaded stationary face made of silicon carbide, both covered with a high-performance coating. The nitrogen separation gas is routed into the seal by using axial bores through the stationary face into the middle of the rotating seat. The purge gas then separates into two leakage flows – one to the inner diameter toward the secondary vent, the other to the outer diameter of the seal face toward the bearing chamber.

Stiff Gas Film Eliminates Risk Of Contact

This aerostatic liftoff design separates the rotating and stationary seal faces as soon as the CobaSeal is pressurized and leads to a wear-free operation. The stiff gas film eliminates the risk of contact between the rotating ring and stationary seal face during irregular operations, such as axial vibrations or micro movements of the compressor shaft. The CobaSeal has no restrictions with regard to “slow roll,” “turning gear” and “coast down” operations of the compressor, which are integral to the demand-driven requirements of a major gas delivery network.

The design allows operating pressure of up to 10 barg in the vent line, combined with differential pressure control, which is an additional safeguard against a total failure of the tandem seal arrangement. Also, the risk of process gas leakage toward the bearing brackets is eliminated.

The new design underwent extensive shop testing, including the simulation of upset conditions as well as operations at maximum design specification. The seal was tested first for EagleBurgmann’s specifications and then subjected to a witness and acceptance test created especially for field conditions at National Grid.

All tests were passed, including the simulation of a total failure of the dry gas seal in combination with the pressure-controlled supply of the coaxial seal barrier. Following testing, the seat and faces of the tested coaxial seal were in “like-new condition” with no contact marks, showing the maintenance of separation, essential for extended safe and continuous operations, worked as intended.

New Seal Standing Up Well In Field

That’s continued to be the case at Nether Kellet since the August 2011 installation of a CobaSeal on a compressor with a 102-mm shaft circumference.

From an operational standpoint, the coaxial barrier seal has improved compressor availability with extended maintenance intervals. Since installation, unplanned compressor downtime has basically been zero.

That’s echoed by National Grid’s own assessment. Nitrogen consumption is less than half of the rate for a carbon ring seal, in line with results from pre-delivery testing. And there has been no evidence of lube oil in the secondary vent line of the compressor. All of this suggests National Grid can expect wear-free seal operation with maintenance intervals extended up to 10 years.

The CobaSeal design can be adapted to all standard seal cavities. The design has been certified by Siemens Energy for use with its compressors.

Authors:

Henk Blekkenhorst is senior compressor engineer at Siemens Energy Service in Hengelo, Netherlands.

Christian Bonfert is senior expert at EagleBurgmann Germany in Wolfratshausen, Germany.

Huub de Bruijn is head of the compressor in the Service Product Management Department at Siemens Energy Service.

Ferdinand Werdecker is head of engineering compressor seals at EagleBurgmann Germany.

Mike Marcinko is senior asset investment engineer at National Grid UK Gas Transmission.

Comments