March 2013, Vol. 240, No. 3

Features

Unlocking The Potential Of Unconventional Gas

(Editor’s Note: The Shale Revolution has the greatest potential to shape the global energy industry since Edwin Drake drilled the first oil well in Pennsylvania in 1859. There was never any secret that shale formations held unimaginable reserves of oil and gas. Developing those resources economically and in an environmentally safe way was always the big challenge. Three entities can be credited with helping to provide those answers: the U.S. Department of Energy, Gas Technology Institute and visionary Texas oilman George Mitchell, who knew that someday – and soon – science would unlock the mysteries of shale.)

George Mitchell, former head of Mitchell Energy and Development Corp., is renowned for pioneering drilling and completion technologies that allowed gas to be extracted from shale formations. The geologist and petroleum engineer, known as the father of the Barnett Shale, enabled viable production through the first successful application of horizontal drilling, microseismic imaging, and hydraulic fracturing applied to the Barnett Shale. His vision and passion for unconventional development changed the energy future in the United States and has the potential to significantly impact the world.

This successful extraction of gas from the Barnett Shale formation in Texas in the 1990s, considered to be the event that kicked off the U.S. shale gas revolution, relied heavily on hydraulic fracturing and other exploration and production research in unconventional gas funded by the U.S. Department of Energy (DOE) and Gas Technology Institute (GTI)—then known as Gas Research Institute (GRI)—and was able to dramatically improve production results.

“GTI played a key role in developing hydraulic fracturing and microseismic technologies that are widely used to this day,” said Kent Perry, vice president, onshore programs, Research Partnership to Secure Energy for America (RPSEA) who served for more than 20 years as an R&D manager at GTI.

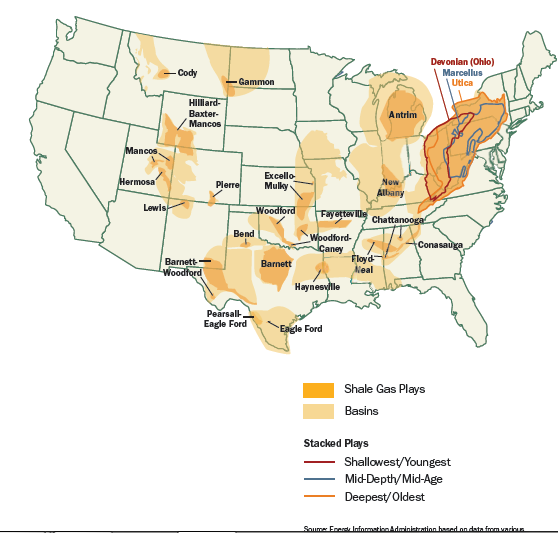

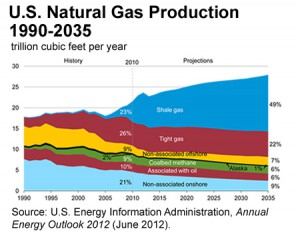

Early research work by DOE and GTI were critical elements in unlocking the vast potential of America’s “new” natural gas, providing the world with a promising new energy future. Consider this: In 1990, unconventional gas accounted for approximately 10% of total production. Today, it accounts for nearly 60% of total production, with gas shales driving this growth. Gas shale already accounts for one-third of North American natural gas production, and is anticipated to reach 49% of U.S. production by 2035.

Early Unconventional Gas Research

Innovation and progress in the development of hydraulic fracturing, microseismic imaging, horizontal drilling, and other key gas recovery techniques stemmed from public-private research and commercialization efforts.

In the late 1970s, DOE-funded research resulted in advanced exploration and production technologies that enabled new gas supplies by increasing per-well gas recovery efficiencies and lowering unit development costs in eastern gas shales. In the early 1980s, DOE’s Multiwell Experiment (MWX) developed technology to enable economic production from low-permeability lenticular gas sands of the western U.S.

Also in the early 1980s, GTI launched a new collaborative research model that brought together a world-class team of experts from industry and academia. Together, the DOE/GTI R&D programs became a catalyst for experimentation and new technology development.

“GTI continued the early theoretical work done by DOE, took it into the field, tested it, and perfected it,” said Vello Kuuskraa, president, Advanced Resources International (ARI), the reservoir engineering contractor that worked with GTI on field experiments in coalbed methane and shale gas. “They turned science into technology and technology into reserves of gas.”

Over the years, GTI partnered with industry, national laboratories, federal government agencies, universities, service providers, and geologic survey organizations — as well as producers that included BP Amoco, Shell, Texaco, Chevron, Mitchell Energy and others.

“The approach was different from previous efforts in that it had very strong industry involvement in the field,” said Perry. “Projects were tested and validated on industry wells, which was critical to the success of the program. We were able to piggyback our testing on million-dollar wells — something that GTI and the research programs could not afford on their own. That field laboratory testing was essential.”

This collaborative model has been proven successful in field programs that explored coalbed methane, gas shale, and tight sands, and has led to significant advances in best practices, processes, and procedures.

Contributions To Hydraulic Fracturing

GTI’s hydraulic fracturing research began as early as 1983, leading to “proof-of-concept” experiments at its Hydraulic Fracture Test Site (HFTS) in the Rocky Mountains. “All kinds of leading-edge technologies were verified in those field tests,” said Perry. “It included drilling wells for research purposes only, verifying hydraulic fracturing, micro-seismic, and much more. It laid the foundation for everything that is happening right now.”

This early field work was critical in improving the industry’s understanding the fundamentals of hydraulic fracturing. “One major achievement of GTI was development of a model for designing and predicting the behavior of hydraulic fractures that included real-time monitoring of fracturing parameters such as rate, pressure, and viscosity,” noted Iraj Salehi, GTI Senior Institute Scientist, who was involved in GTI’s tight gas sands research from the 1980s on. “It’s a technology that the industry is still using today.”

Hydraulic fracture modeling was validated by both mini- and post-fracture measurements to establish a scientific basis for hydraulic fracturing, which until that time was more an art than a science. The work went beyond just analytical models — GTI developed diagnostics and ran lab experiments in the field to determine where a fracture goes (propagates), how far it goes, and what parameters control its destiny. One of GTI’s shallow coalbed methane wells was mined back, so pictures of the actual fractures were taken as the seams were exposed, providing amazing validation.

From the 1980s through the 1990s, “GTI developed methods for monitoring the creation of hydraulic fractures which led to the development of microseismic imaging of fractures,” said Salehi. “We also worked with Sandia [National Laboratories], which was also heavily involved in fracture imaging, to develop a downhole tool. GTI was a key contributor to advancing fracture diagnostics technology.”

A key technique, FracSeisSM microseismic hydraulic fracture mapping for fracture diagnostics, was developed by GTI to help gas producers plan and conduct effective and economical hydraulic fracturing operations.

Advancing Understanding Of Unconventional Gas

In addition to developing technological advances, GTI contributed greatly to the industry’s understanding about unconventional gas resources and ways to optimize production. “We helped the industry characterize the resource and determine its potential,” said Perry.

Coalbed methane. As a result of its early work in the 1980s, GTI provided a fundamental understanding about coalbed methane upon which others have built their technologies. It determined that, because of the way natural gas is adsorbed onto the coal and, in some cases, the presence of significant volumes of water, coalbed methane is not produced like other resources.

As a result, a new strategy was developed that took into account the mechanisms needed for dewatering, resource evaluation, determining the amount of gas in place in an adsorption environment, and fracturing in coal. As cost-effective alternatives to reinjection, methods for environmentally acceptable discharge of the mineral-laden water often produced with coalbed methane were developed. GTI also developed guidebooks to help producers optimize all aspects of coalbed methane operations.

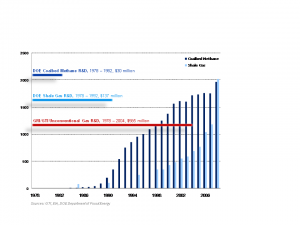

GTI researchers led a comprehensive program to document those regions with the greatest coalbed methane potential, providing assessments of recoverable coalbed methane in six major geologic basins and comprehensive models for two major basins in New Mexico and Alabama that Amoco and Arco (now both BP) and other producers used to evaluate drilling risks, design fracture treatments, and educate investors. When GTI began its coalbed methane R&D in the early 1980s, production across the U.S. was less than 50 Bcf per year. It is now upwards of 1,800 Bcf per year.

Tight gas sands. GTI also contributed to the industry’s understanding about how to increase the amount of cost-competitive gas recoverable from tight gas sands. While significant amounts of potentially recoverable natural gas exist in low-permeability sandstone formations in sedimentary basins throughout the U.S., a combination of technical and economic constraints had historically been preventing the widespread commercial exploitation of these resources.

An integrated research program led by GTI focused on improved geology and resource parameter quantification, enhanced stimulation techniques, and improved fracture diagnostics for determining fracture azimuth, fracture height, and overall fracture dimensions.

The research team designed and implemented open-hole data acquisition programs on a series of wells identified as the staged field experiments (SFEs) that worked to determine the most effective combination of formation evaluation (geological, petrophysical, and engineering), fracture diagnostics, hydraulic fracturing, and fracture modeling techniques to reduce the cost of producing gas from tight formations.

The SFEs were critical because of the need for field testing, interaction with producers, enhanced technology dissemination, and technology development. Though they were costly, dedicated research sites in the field were essential to move technology forward — a real-world laboratory that enabled model validation and optimization of fracture dimensions, and included coring, MWD logging, wireline logging, open-hole stress testing. Pre-fracture, mini-fracture, and post-fracture analysis were also conducted.

Gas Shales

Research on gas production from shale resources has yielded significant new knowledge, enabling the industry to improve its understanding of the character of shale reservoirs in U.S geologic basins.

An early effort in the Michigan geologic basin involved field experiments in the Antrim Shale that helped the industry better understand fracture geometry in this complex formation—eventually taking it from a little-known resource to a cost-competitive source of natural gas. The Antrim was really a combination of both coalbed methane and shale technologies—shale evaluation methods were used, but because the Antrim contained water, it required dewatering similar to coalbed methane.

By studying 2,000 wells, GTI developed methods that could double production rates. GTI also devised new ways to assess gas content in core samples in as little as one day and to use existing well logs and the new sampling method to help find gas beyond current wells.

GTI also pursued research on gas production from shale formations in Illinois and Texas. Several horizontal wells in the Barnett Shale were tested and evaluated with multiple fracture treatments, and a calibrated formation evaluation was performed with a cooperative Mitchell Energy well.

In 1991, GTI funded Mitchell Energy’s first successful horizontal well in the Barnett Shale in north central Texas, together partnering with DOE to develop tools that would effectively fracture formations. GTI’s micro-seismic imaging data proved particularly useful throughout the 1990s when Mitchell Energy would make the final key innovations credited with “cracking the Barnett.” In 1998, Mitchell Energy reached a milestone as engineers achieved commercial shale gas extraction.

Having successfully demonstrated multi-fracture horizontal well drilling techniques in the Barnett, engineers had to develop the optimal combination of inputs – water, sand proppants, chemical lubricants, etc. – to achieve maximum gas recovery at the lowest cost possible. In 1998, Mitchell engineers applied an innovative drilling technique called ‘slick water fracturing’ (or ‘light sand fracking’) that brought fracture job costs down to around $100,000 compared to $250,000-300,000 for MHF projects. This is widely considered a milestone that pushed shale gas into full commercial competitiveness..

“The big breakthrough was in drilling the Stella Young well with Mitchell Energy in the Barnett Shale,” Kuuskra explained. “This was a novel well drilled at a high angle, rather than vertically, then stimulated with modern-day technology. That well had three times greater production than anything else that had been drilled to date. It established that, if you can fracture a well and increase reservoir contact, you can significantly improve the productivity of these deep shales.”

In 2002, when Devon Energy Corp. acquired Mitchell Energy, it combined hydraulic fracturing with horizontal drilling to further improve the productivity of shale gas wells. “That was the a-ha! moment that truly kicked off the production at Barnett, Marcellus and all of the other great shales that are now producing gas in greater volumes than ever before thought possible,” Kuuskra continued. “GTI’s willingness to take scientific risks to see whether theories would work in a real-world setting pushed everything forward. It takes something like that to break the technology lock.”

Future Of Unconventional Gas

GTI is providing new tools, data, and thought leadership to ensure the safe, economical, and responsible development of global shale gas. The Energy Policy Act of 2005 called for development of an industry-led public/private partnership for R&D in the production of unconventional natural gas and other petroleum resources. Section 999 of that Act allocated $37.5 million to RPSEA, a nonprofit consortium of premier U.S. energy research universities, industry, and independent research organizations.

GTI leveraged their expertise in managing the onshore unconventional program for RPSEA from 2006-2011 and continues to serve as a major technical performer in the program. The program focus is on developing gas shales in an environmentally acceptable manner, including development and deployment of technology to mitigate the impact to land, air, and water resources.

In 2011, GTI signed a $4.5 million contract with RPSEA for characterization of the Marcellus Shale and development of advanced well completion technologies and best practices that address technical and environmental challenges for this resource. The project is focusing on identifying the optimum techniques for enhanced fracture stimulation and reliable reservoir assessment.

In 2012, GTI was awarded RPSEA funding to develop advanced methods and techniques for design and execution of environmentally safe and economically efficient hydraulic fracturing operations. The two-year project will develop a real-time hydraulic fracturing control methodology through coupled analysis of geophysical fracture diagnostic data and pumping pressure, rate, and fluid density; and verification of results by detailed production testing.

Included in this project is a planning workshop for a new Hydraulic Fracturing Test Site which GTI is hosting in early 2013. The objectives of this collaborative test site are to develop a greater understanding of the dimensions and productivity of hydraulically created fractures in long horizontal wells, enhance the efficiency of each hydraulic fracture stage, reduce completion costs and minimize environmental footprint.

Water management. As the country moves increasingly toward development of unconventional resources, the importance and use of hydraulic fracturing has grown exponentially. In the U.S, thousands of wells are hydraulically fractured every year and the water used in the process has become a perceived environmental risk with the general public and key stakeholders.

For several decades, GTI has worked with representatives from academia, government, and industry to develop solutions for the conditioning of produced waters to enable environmentally sound and cost-effective management, by-product recovery, and beneficial use of produced water streams.

One key technology developed by GTI is the FTE® Process, a freeze/thaw evaporation process for treating produced waters. Partnering with DOE, Amoco Production Company, University of North Dakota Energy & Environmental Research Center, and the U.S. Bureau of Reclamation, GTI developed a unique and cost-effective method for produced water treatment that capitalizes on naturally occurring temperature variations to reduce water management costs.

During the first decade of the 2000s, GTI has led Water Conservation and Management Committees in the Barnett and Appalachian shales, performed work for the New Albany Shale and Marcellus Shale Research Consortia, and assessed water management and reuse technologies for RPSEA. Researchers are utilizing water-based life cycle modeling to provide timely planning and technology guidance for sustainable shale gas water and solid waste management.

In 2011, a techno-economic assessment of water management solutions was completed, a joint industry project with 22 companies. The study defined water management practices, emerging solutions, and benchmark costs; categorized best-in-class options; and identified technology gaps and opportunities for cost reductions and efficiency improvements. GTI is also providing objective, third-party evaluations of client technologies from methods to fracture stimulate unconventional resources more efficiently to systems for treating flowback and produced water more economically.

A portable water laboratory platform planned for development will monitor for the presence of corrosion-causing microorganisms within oil and gas production sites and mitigate operational costs associated with bio-corrosion, gas souring, and water treatment.

Sharing expertise. GTI is working to share lessons learned from the U.S. unconventional gas revolution with the rest of the world. One key international initiative is the Global Unconventional Gas (GUG) Summit held in Beijing, China in November 2012. The event, building on the success of the 2011 meeting in Beijing and the 2010 conference in Amsterdam, focused on the exchange of ideas about the enormous potential of gas shale and the unlocking of unconventional gas resources in an environmentally and economically sustainable way.

Co-hosted by GTI and the China Energy Research Society, the event provided an elite meeting place for more than 220 senior-level International and Chinese energy experts, along with first-class speakers from the global gas industry and governmental bodies. A series of high-level signing ceremonies and networking events took place at the Summit, including the signing of a framework cooperation agreement for a training and learning center between SPT Energy Group and GTI.

In addition to these global meetings, GTI delivers customized workshops on best practices and technological solutions for unconventional gas development and produced water management to European producers and service companies. Expert papers and presentations are sharing the U.S. expertise and advocating for unconventional gas development across the nation and across the globe, in far-flung locations that include Austria, Poland, Istanbul, France, the Netherlands, and Korea.

GTI completed a study in 2012 in support of the Polish operator’s association to assess industry best practices toward addressing potential environmental impact of shale gas exploration and appraisal activities. The public report is being used by Polish industry in external communications regarding technology applications and sustainable practices, both with government and communities.

What’s Ahead?

As George Mitchell discovered, it takes the collaboration of the right partners and technology-based solutions to make unconventional gas resources productive. Today, the industry continues to face distinct and diverse challenges in optimizing the development of each resource in addition to the need for technology transfer and support. Shale gas has needs for ongoing R&D in the areas of data management and optimized efficiency. Though produced water management has been the most visible environmental solution needed, there are also challenges in air quality, noise, truck traffic, solid waste generation, surface disturbance, and induced seismicity that need to be addressed. Hydraulic fracturing effectiveness and enhanced treatments need further development to move forward successfully and technology needs to be evaluated and validated in the field to optimize performance.

Collaboration between producers, service companies, NGOs, policymakers, thought leaders, industry associations, universities and investors combined with the right advances in technology will be crucial for unconventional resources to reach their full potential. Third-party science—producing independent, peer-reviewed studies and similar data—will help greatly in promoting stakeholder acceptance.

As illustrated by the legacy of unconventional gas development in the U.S., R&D supported by private industry, federal government, national labs, and research organizations has made a difference in gas shales development, and the benefits of research far outweigh the costs by orders of magnitude. Ongoing R&D is needed to ensure that abundant, affordable, and clean unconventional gas can be produced in an environmentally and economically sustainable way. New tools, data, and thought leadership will help to ensure the safe, cost-effective, and responsible development of global resources and provide tremendous opportunities to take advantage of the many positive attributes of natural gas.

Built by Amoco in the 1980s as a proprietary test site, GTI Catoosa became part of GTI in 2000 to provide an all-in-one development and testing environment for new downhole tools and technologies.

Located on an 80-acre site located near Tulsa, OK it provided critical services for the evaluation of advanced technologies associated with the drilling of natural gas and oil wells. It offered rigs and support equipment designed to allow rapid and low-cost drilling operations, a wide range of wellbore configurations, a full-service machine shop, and live downhole data acquisition capabilities through 2010.

Over the years, a “who’s who” of oil field service companies performed thousands of real-world new technology evaluations and major manufacturers from around the world visited the site for its unique features and experienced staff.

Comments