December 2013, Vol. 240 No. 12

TechNotes

Foley Engine Rebuild Center Serves the Gas Compression Industry

Cat dealer Foley Equipment, operating in Kansas and northwest Missouri, provides complete services on all Cat engines and engine components from its 127,000-square-foot rebuild center in Park City, KS.

Foley can rebuild all sizes of engines, from the smallest 3304 engine up to the monster 3616. Engines come into the center from all over the globe with 70% of the rebuilds completed coming from the gas compression industry.

After arrival at the rebuild center, engines go through a full-failure analysis process, followed by a complete rebuild vs. replace assessment. Engines are washed down and all fluids and electronics are removed. If necessary, the engine is sent to shot blast for paint removal after which it is completely disassembled.

Disassembled components go to one of four rotating wash cabinets, which can spray 1850 F. cleaning solution at up to 175 psi. As an engine moves through the facility, each component removed from an engine is tracked through the rebuild process ensuring that the components stay together and the engine maintains its original configuration and identity.

Cleaned components are inspected, including a Magnaflux magnetic particle inspection system to find cracks in the blocks, crankshafts and cylinder heads. There is also a 9,000-square-foot parts warehouse onsite with more than 60,000 line items on site supporting the remanufacturing operation.

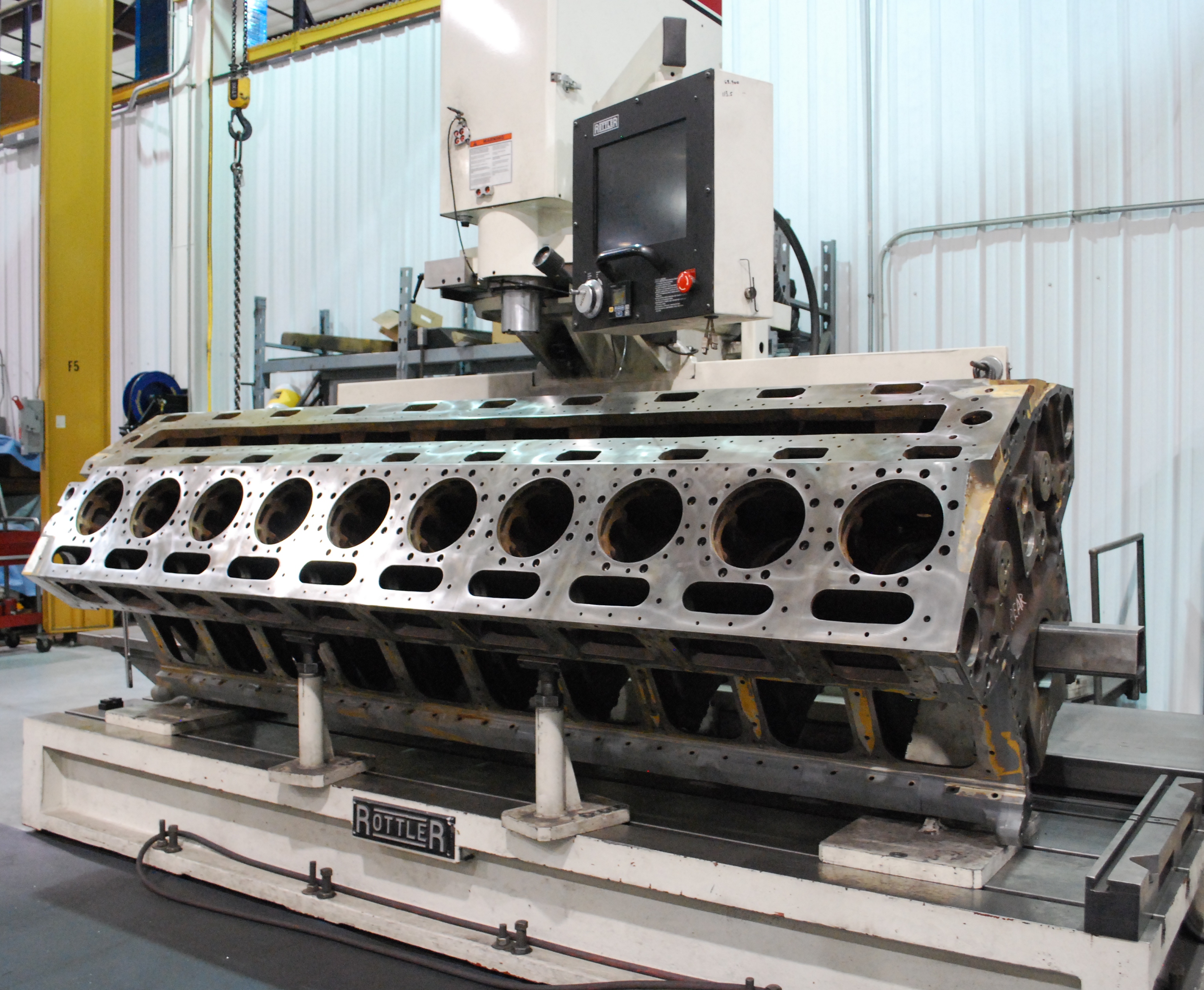

From disassembly and inspection, the engine block and heads are sent to the machine shop for inspection and necessary machining. The engine block is quality checked for line bore, heads and block milled and crankshaft polished. New valve seats are installed. If the cylinders were over-bored, new sleeves are inserted. The machine shop has spray weld capabilities to replace metal and then all surfaces are machined back to original specifications.

After the machining is completed, the engine is reassembled. Every engine is sent to one of two dynos for testing. Foley has one of the first 5,000 hp dynos installed in the U.S. capable of handing the 3616 engine, in addition to a 1,500 hp. dyno. After testing, the engine is prepared for shipment to the customer.

Foley has a fleet of 25 to 30 exchange engines onsite at any given time, a combination of new and remanufactured models, allowing customers to switch out like models. That size of fleet can reduce downtime to only a day or two in some applications. The exchange fleet includes many models up to the G3516.

Comments