September 2012, Vol. 239 No. 9

Features

Compressor Control Moving Beyond Black Boxes

Compressors play an integral role in the oil and gas industry, helping power the multiple processes that convert oil and gas into thousands of practical products. Yet even today – more than 150 years after the birth of America’s petroleum industry – these critical components are not integrated into the control platforms of most petrochemical plants.

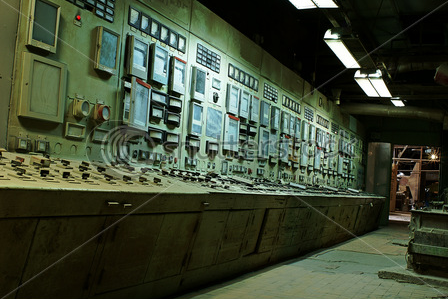

Instead, compressor controls are often housed in “black boxes,” mounted in separate panels inside a plant’s command center. These panels usually contain customized instrumentation used to keep the plant’s turbomachinery operating within a normal range. The primary goal is preventing surge – sudden, destabilizing flow reversals that can seriously damage the compressor itself and lead to costly repairs, plant downtime and even environmental consequences.

Until recently, many in the petrochemical industry considered black boxes the best available technology to maintain consistent compressor control, despite the technology’s many drawbacks. Chief among those: the lack of interoperability with other plant controls, the difficulty of quickly accessing critical operating data, the need for specialized tools to maintain or expand compressor control systems, and the demand for more redundancy and energy efficiency.

But today, a growing number of global oil and gas companies are abandoning their black boxes for programmable automation controllers (PACs), taking advantage of their state-of-the-art, high-performance capabilities.

Today’s PACs combine the features and capabilities of a PC-based control system with that of a typical programmable logic controller (PLC), as well as advanced digital technologies, such as Ethernet/IP and predictive modeling analytics. In addition to eliminating the need for isolated, complicated and often proprietary black boxes, these open, “generic” platforms provide integrated network connectivity, more precise compressor control, and easier scalability to match production demands.

Control Vs. Surge

The purpose of any compressor controller is to operate turbomachinery within safe parameters. Surge is the major enemy of safe compressor operation.

Surge occurs when flow-rates suddenly decrease in the compressor, because of human error or when downstream demand changes. While the flow reversal inside the compressor only lasts a very short time, the resulting unstable pressure can introduce dynamic loads on internal components, such as seals and impellers. Over time, the fatigue on this equipment can lead to failure.

Anti-surge control can interfere with normal plant operations as it attempts to protect the compressor often at the expense of the process. This drove the addition of process-related functions, such as capacity control, into the black boxes to lessen the impact of the anti-surge control and smooth out process upsets.

Evolution Of Compressor Control

Oil and gas producers in the mid-1900s worked with controls vendors to develop rudimentary pneumatic compressors as well as electronic proportional-integral-derivative control systems which helped minimize flow by adjusting process-control inputs.

While these methods prevented surge, they consumed a lot of energy. That became a major drawback during the oil crises of the 1970s, when Middle East crude-producing countries severely cut exports to the United States. Even after tensions eased and the flow of foreign oil resumed, energy prices continued their steady rise. This prompted engineers to focus on more energy efficient compressor controls.

The nascent distributed-control-system (DCS) and PLC platforms that existed at the time lacked the computational speeds necessary to generate a control output in less than 100 milliseconds. To meet these requirements, engineers created specialized control hardware – the black boxes. At the time, the oil and gas industry still relied primarily on rather primitive panel-mounted instruments, so the specialized black box approach was the only solution.

During the 1990s, federal officials enacted stricter regulations to improve safety and environmental protections in many industries, including oil and gas. These changes began to reveal the many shortcomings of black boxes.

Hardware changes and firmware revisions were seldom easy to implement and often required a redesign of the controls. That meant revisions tended to be expensive and could result in facility downtime unless integrated with planned maintenance.

Advantages Of Generic Control Platform

Meanwhile, the PLC- and DCS-based control industry was rapidly developing new system architectures based on advances in computer-processing technology. These systems featured expanded computational power and increased execution speeds, offering huge potential to improve operations and increase efficiency.

Black box vendors also added advanced features to their devices, but there are limits to what can be accomplished in a small self-contained package. Because they were developed on a variety of proprietary platforms, the block boxes were largely incompatible with one another. Supporting these multiple, incompatible systems increased costs for oil and gas producers and as a result, limited their applications.

Frustrated by these limitations, end-user companies began to push for a common set of programming standards to simplify system-engineering and provide a consistent approach to control implementation. The result of these efforts was international standard IEC-61131. Published in 1993 and updated in 2003, IEC-61131 is a family of programming languages for PLCs that are the most commonly used worldwide.

This common computer language – combined with the availability of generic control platform equipped with Ethernet/IP connectivity and high-speed modeling analytics – has raised this question for oil and gas companies: Why buy a black box when you can get an integrated compressor control system that offers far better performance and greater flexibility – all at a lower cost?

The answer seems to be that many end users are unsure or unaware of the larger control system capabilities and cost-effectiveness. They should consider these advantages to integrating their compressor control with their main platform:

Communications: Unlike black boxes, generic platforms support common communications media, protocols and standards, including serial Modbus, DeviceNet, ControlNet, Profibus, Ethernet Modbus, EtherNet/IP, and open connectivity over Ethernet. Some platforms are even capable of wireless communications.

Scalability: Black boxes each have a fixed function and a fixed amount of I/O, so if a process changes, requiring additional functionality, many producers must add another black box. Today’s PACs can be sized for each specific application. As a result, oil and gas companies can cost-effectively apply these systems to processes of any size, which helps drive operational improvements to each level of the facility. System changes and maintenance can be performed with common IEC-61131 toolsets, which eases operator training and minimizes downtime. Future smart field devices also will be easier to integrate with generic platforms.

Diagnostics: With limited operator interface capabilities, black boxes pose obstacles for maintenance technicians trying to determine the cause of a fault. Error codes typically don’t provide enough information to adequately troubleshoot issues with the controller. But PACs allow greater access to interpretation of controller data.

Redundancy: With modern PACs, redundant and even triple modular redundant platforms are available, offering oil and gas companies access to whatever level of fault tolerance their application requires.

Spare Parts and Training: The specialized nature of black boxes requires expensive spare components and trained personnel to maintain the systems. Because generic control platforms often are used in multiple areas of the facility, oil and gas producers can implement a single hardware, training and technical support solution that greatly reduces their total cost of ownership.

System Architectures: The typical architecture approach for a turbine-driven compressor (figure 1) requires significant hard-wired and communication interconnections to integrate each control function. In addition, an auxiliary PLC is required to handle functionality that is beyond the scope of the black box controllers, such as lube oil-control, compressor seals, start-up sequencing, interlocks and permissive.

The interface of all these devices, each from a different vendor, requires careful design. If one piece of hardware fails or loses communication, the entire system may shut down. Faults may be difficult to isolate to a particular device, and start-up sequencing can become a challenge, which forces plant operators to operate subsystems in manual mode, increasing their work load and compromising system safety.

On the other hand, generic platforms can integrate multiple tasks within a single platform (figure 2), which simplifies hardware interconnections and communications, and lowers installation costs. In fact, entire subsystems can be eliminated, further reducing expenses, while offering the many benefits of standardized hardware and software solutions.

For all these reasons, black boxes are destined to become the dinosaurs of compressor control, as oil and gas companies realize the full potential of integrated and automated process control.

The Author

Rick McLin has more than 25 years of experience in turbomachinery controls (TMC) as an end user and leader of development teams in the U.S. and abroad. He spent 16 years at one of the largest oil companies in the world developing surge control algorithms and implementing distributed control systems in oil and gas production facilities.

From the end-user role, he moved to product development positions with TMC suppliers developing turbomachinery products and applications implemented on various control platforms from simplex to triple modular redundant hardware. McLin joined ICS Triplex in 2003 as TMC business manager where he established the development group, and implemented compressor and turbine controls. When ICS Triplex was acquired by Rockwell Automation, he led the group porting the TMC libraries and algorithms to the Logix Control Platform and developing of the latest generation of Rockwell Automation packaged TMC products.

McLin also led the development of the subsea compressor control and safety systems developed for Statoil in the North Sea.

Comments