October 2012, Vol. 239 No. 10

TechNotes

A Redundant, Immune, Calibrated Gas Detector

OptoAcoustic gas detection determines gas content via the measurement of acoustic pressure waves that are propagated as a gas is irradiated under an appropriately tuned light.

A gaseous mixture sample passes through a membrane into a measurement cell which contains an optical light source and a microphone. Incident light modulated at a specific frequency is briefly absorbed as intermolecular energy by the gas molecules and then released as translational energy, creating periodic temperature and pressure changes that generate measurable acoustic pulses.

The novel dual-cell detector is comprised of two separate and identical cells that act interchangeably either as the primary gas-measurement cell or as a secondary compensation cell. The secondary cell is also used as a redundancy measure – industry’s first redundant gas detector with active sensing element plus backup sensing element in the event of primary cell failure.

The gas sensor has been engineered to sustain harsh conditions at drilling and production platforms or gas wells, refineries, gas processing facilities, compressor stations, chemical/petrochemical installations and LNG, NGL and propane plants, where they withstand vibration, temperature, and humidity extremes.

The sensor requires less frequent maintenance due essentially to its embedded self-diagnostics, false alarm rejection and temperature compensation algorithms.

Unique Features And Benefits

The OptoAcoustic gas sensor is the first sensor worldwide that does not require Calibration in the field, and the unique sensor to provide redundancy- backup system within the same detector. It has no consumable parts – i.e. the target gas does not consume the sensor, thus immunity. The sensor is also immune to temperature & humidity fluctuations, it has an infinite shelf lifetime and an operational lifetime of minimum 15 years.

Retrofit Compatibility

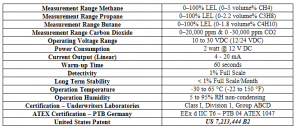

The OptoAcoustic gas detector is suitable for new as well as retrofit installations. The OptoAcoustic gas detector is compatible with any controller or PLC that provides power of 12 or 24 VDC, and takes input readings of 4-20 mA. The range 4-20 mA is equivalent to 0-100% LEL, already linearized and calibrated. No further calibration is required. After wire-and-power, the sensor is operational after one minute warm up time.

Comments