November 2012, Vol. 239 No. 11

Features

Training A Measurement Technician

The need for good quality measurement has increased dramatically in recent years. Deregulation of market pricing structures, open access markets, increased exploration and drilling costs, fierce competition and new regulatory requirements have all influenced today’s approach to quality measurement methodologies. In fact, the terminology has evolved from “gas volume measurement” to “total energy measurement.” Today, not only is the volume of gas a consideration, but also the quantity of energy the gas produces. The gas industry has evolved from the MMcf to the MMBtu.

As technology has advanced, there has been a greater sense of urgency for employee training. The open-access market, which moves greater quantities of gas volumes with considerably more competitive profit margins, has become a reality in recent years. Measuring stations at transportation interconnects require a degree of accuracy that necessitates measurement personnel highly skilled in today’s technology.

Such equipment as chromatograph analyzers, automatic samplers, electronic flow computers, pressure and temperature transducers and remote terminal units has come to the forefront of technology. New communication structures such as satellite systems, radio frequency data transfer, high-speed telephone modems and cellular communications offer greater challenges to the field technician.

Current reorganization trends that flatten company structures translate into a leaner workforce. Utilizing fewer employees to accomplish a higher degree of productivity with emphasis on becoming safer while being customer-focused requires a greater training effort.

An adequate training program is essential to meet the demands of increasing technological advances in the gas industry. Knowledgeable, skilled personnel are a key factor for a company to remain successful and competitive through this transformation process and into the future.

The obvious question to many companies is, “How can this challenge be effectively met?”

Training Options

While some companies traditionally offer training to satisfy legal requirements, training can have a tremendous impact on productivity, economics and safety in the workplace. Effective training of technicians and other key personnel may greatly impact the bottom line financials of a company.

Traditional “off-the-shelf” training videos or external training sources are not always adequate to meet the specific needs of the measurement technician. “Tailgate field sessions” may be helpful but seldom satisfy the overall requirements of the team at large. Successful training must be focused on the actual job-related conditions. Some common questions are: How does the technician ensure that the gas sample is representative and delivery to the lab is complete? How are chromatographic problems resolved? Do flow computers reflect an overall picture of the gas volume? Does the Rtu communicate effectively to the SCADA system for real-time operational scenarios? These and numerous other considerations require a comprehensive approach to the training program for successful results.

While there are many options available for training an employee, a number of companies choose to operate their own training facilities. There are many benefits to offering in-house training, some of which follow:

1. In-house training affords an excellent medium for extending practices and/or procedures into daily operational practices. Updates and/or changes are readily disseminated to the employee on a company-wide basis.

2. As employees from various locations attend the training, consistency in operational practices reaches all areas of the system. A vital goal of any training program is to convey a uniform message.

3. Students train on specific types of field equipment with which they are responsible in their respective job duties. Emphasis is placed on hands-on training at the training center as well as classroom instruction.

4. A training facility equipped with a flow lab provides an excellent “real world” environment to train employees in specific operational problems encountered in their jobs. It can be utilized as an effective testing resource when employees require technical assistance and can serve as a research and development center.

5. A centralized training facility can also serve as a benefit if it is strategically located geographically to the advantage of the entire system.

6. Safety, being an integral part of each course, includes training to perform each task safely, as well as technically correct.

7. Operator qualifications can be offered in a centralized setting including knowledge and skills assessments.

Planning And Analysis

Before a training facility is established, other training considerations need to be considered. Identifying the audience and the levels of learning will help establish how extensive the training needs to be. Needs analysis is essential to identify and target the specific requirements of the employee and the company. This process involves a study of corporate goals and job task analyses that support the long-term goals. The training must enhance the employee skills associated with the specific tasks required to comply with their job functions.

Recognizing the importance of “customer satisfaction,” it is an important consideration to survey the operating districts and/or business units to determine their specific needs. The survey provides a quantifiable database for determining a level of interest in:

1. Courses previously presented in-house,

2. On-the-job training, and

3. Courses that need to be developed or acquired in the future based on identifiable “gaps” in training.

It may result in a multi-faceted approach to training to meet today’s technology. A combination of classroom instruction, self-study modules, computer-based training, distance learning, go-to meetings and/or the company web intranet and on-the-job training may all become an integral part of the overall scope of the program. Many of these options can be furnished to field locations as a prerequisite to attending the training center or for employees requiring refresher training.

Training courses in electronic formats utilizing Power Point slide presentations and associated formats make the courses accessible to any employee through the company intranet for preview prior to attending a course or to satisfy gap training.

Training Center

The logistics of a training facility are a very important consideration. An adequate number of classrooms and storage areas should be well thought out in the planning phase of the facility.

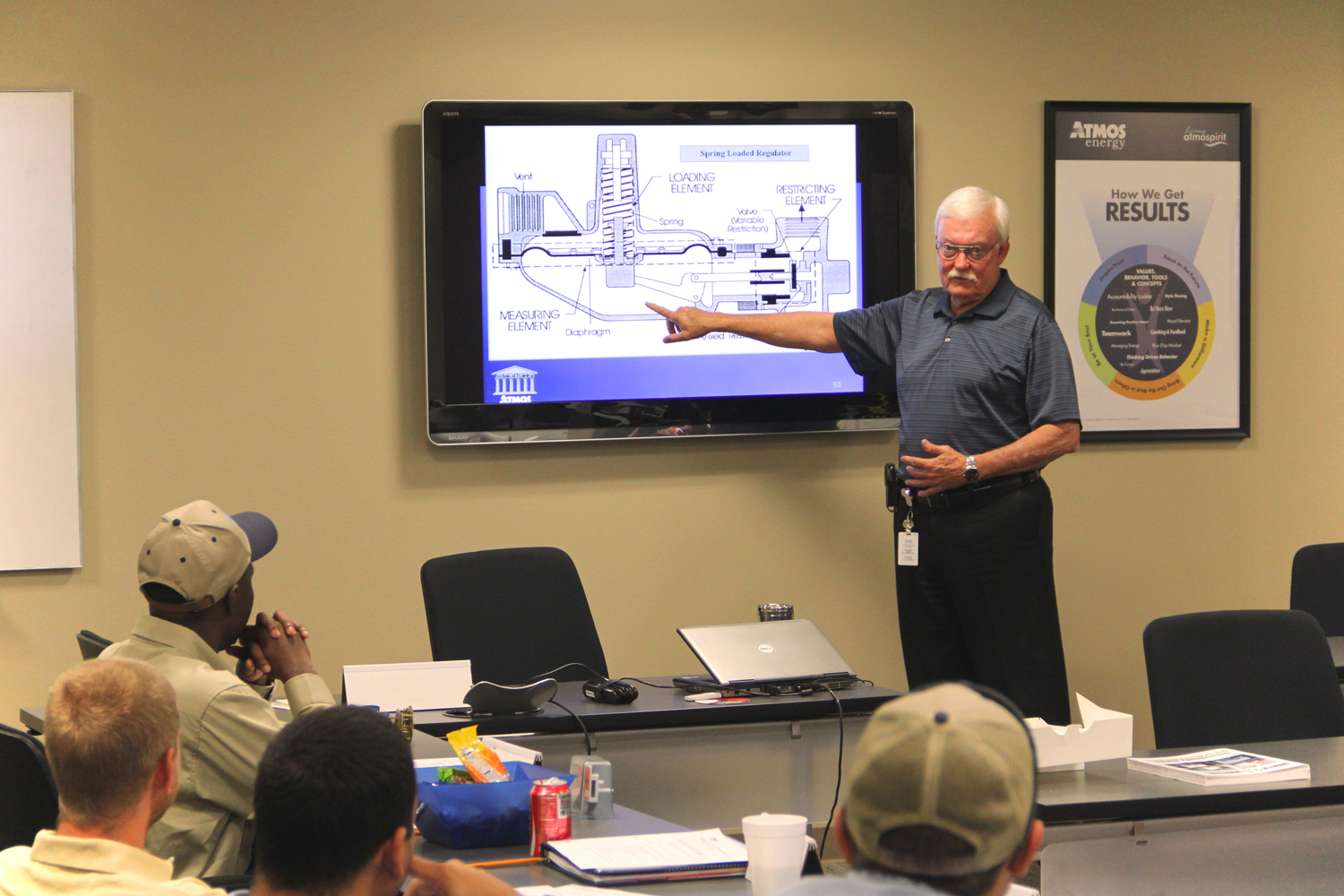

In the classroom, each student should be furnished with an ergonomic work area, complete with pencils, highlighters, notepads and a calculator. The classroom should be equipped with various training aids such as a slide projector, video tape deck, overhead projector and personal computer projector. Cutaway display models of various types of equipment aids the instructor during lectures to demonstrate the equipment. Another effective teaching aide is the use of a desktop personal computer connected to a PC projector. This technology allows the use of software-driven slide shows to accompany the instructor’s lecture. The slide show capability virtually replaces the need for an overhead projector and also supports animation.

Another advantage of the system is that operational software used in the field may be displayed and operated in the classroom setting. Such software includes electronic flow computer, chromatograph, gas sampler, odorizer, cathodic protection, various types of measurement devices and remote terminal unit programs. The PC can be linked to Gas Measurement Services for online volume calculation in the mainframe system and a link can be made for online monitoring of the SCADA system in Gas Control. Using a web browser, the system can be linked to outside resources when required.

An area should be provided for hands-on training. It would consist of workbenches for equipment disassembly/re-assembly with natural gas and compressed air available, as well as a ventilation system. Adjacent to that area, a tool room with multiple sets of tools for the students to use during training should be available.

A flow lab can be an extremely valuable training tool for simulation. The flow lab should consist of almost every type of meter, controller, regulator and relief valve used in the system. All of the meters and regulators can be fitted into the same length of spools so they may be interchanged to suit the particular course being presented. The flow lab should contain flow computers and remote terminal units which can be connected to the Gas Control System to simulate field conditions. The flow through the lab can use air or natural gas for simulated conditions but typically, air is used instead of natural gas for safety reasons, especially if the laboratory is enclosed.

Continuous flow rates representing a wide variation of ranges should be available for training and testing purposes. Considerable volumes can be maintained for limited periods of time by the use of a volume storage tank located near the lab. The lab area should also include all of the latest automatic gas samplers and Btu determination equipment. Those particular instruments can run on natural gas and produce actual results. The flow lab should be designed to allow the instructors to simulate virtually any operational problem that the employee may face in the field. In this way, the students learn how to perform repairs and handle most situations before being subjected to actual emergency situations.

The flow lab is also typically used to test and evaluate new equipment before our company accepts it for purchase. It allows engineering and training personnel to work together on the equipment in a centrally located facility. Equipment considered for purchase is subjected to rigorous testing within its limitations before a purchase decision is reached.

The remainder of the facility can be used for office space, restrooms, storage, break area and a copy room. In some instances, the facility can be multifunctional and serve other purposes such as meeting rooms.

Technical Training Committee

A technical training committee consisting of operations upper management and field superintendents/supervisors, as well as a cross section of field technicians, comprises a valuable team for training decisions. The committee serves to identify organizational and corporate goals for training and to approve the self-study instructional modules which are developed by the instructors for the courses. The training materials must be technically correct, legally defensible and fulfill regulatory compliance criteria before they are published and distributed to the employees. The content typically should support the company’s operation and procedures manual.

Selecting Instructors

There is no single consideration more important than the instructor’s credibility with the students. Selection of effective instructors can be a challenge. The instructor must have an extensive knowledge of the subject matter and an effective classroom presence. The instructor must be able to hold the students’ interest while being technically correct and somewhat entertaining. It is always in the best interest of the program to furnish adequate soft skill training techniques to the instructor, such as, “How to Train Adult Learners.”

Some of the most effective instructors have worked extensively in the field environment and also relate well with students in the classroom setting. Students with field experience can determine within minutes after a class starts how knowledgeable an instructor is on a particular subject.

Training Center Curriculum

The training curriculum should be based on a logical progression program for the measurement personnel. It should begin with fundamentals classes to establish a firm base for the technician to then build upon and eventually progress to advanced or specialized courses.

It is recommended that a structured program be utilized. This would consist of an introductory course followed by effective on-the job training (OJT) preferably with a mentor/coach using checklists to more accurately track a student’s progress and proficiency at the specific tasks that were included in the previous course. After completion of the OJT, the technician returns to the training center for a more advanced overview of additional topics again followed by OTJ and assessment as a follow-up.

After completion of the basic and advanced overview courses and associated on-the-job assessments, the technicians are ready to begin attending specialty courses which include specific instrumentation applicable to their job duties.

The intent of the progression program is to cover a three- or four-year period of instruction to advance the technician to a highly skilled level of proficiency.

Entry Level Overview

An entry level orientation course could include basic mathematics, geometry, gas law equations, AGA calculations and basic chemistry. It should also include instruction on measurement devices, testing and calibration standards, gas quality and fundamentals of gas contracts.

Basic instruction includes the operation and maintenance of spring-loaded and pilot-loaded regulators and pneumatic controllers. Students disassemble equipment that has failed in the field and analyze the problem. Relief valve testing and set-point is demonstrated in the flow lab under actual flowing conditions.

Advanced Offerings

More advanced offerings might include electrical concepts, electronic components, integrated circuits, electronic data transmission and an in-depth study of remote terminal units and electronic transducers. Specific instruction on RTUs, including installation, operation and maintenance of the unit would include instruction on National Electrical Code compliance in coordination with company policy. In the flow lab, students can operate/download to an RTU from a laptop computer, calibrate transducers and observe calculated gas flow, pressure and temperature on display in actual flow conditions.

Training can include instruction on how to install, calibrate, operate and maintain electronic flow computers. This includes discussions of basic flow measurement techniques. Flow computers can then be observed online in the flow lab when interfaced with a laptop computer. Collections and calibrations are performed. Specialty courses may include specific topics such as: gas quality, chromatography, electronic flow computers, pipeline fluid dynamics, metrology, pneumatic/electronic controllers, control systems, advanced electrical/electronic theory, and electrical grounding.

Class Structure

Each class should be limited to a maximum of 8-12 students, depending on the particular course. This size group provides for better class participation and allows each student to operate the hands-on equipment being demonstrated. The class setting should be informal so students are encouraged to participate in class discussions, ask questions and share helpful information dealing with problems they may have encountered on the job. This sharing of experience is a valuable training tool and an added benefit of bringing employees together from different locations.

At the end of each course, the students take a final exam to determine what they have learned. The final grade is based on an average of the final exam, class participation and hands-on participation (if applicable). A passing score is typically 70% or better. If a student does not demonstrate sufficient proficiency in the course, their supervisor is notified and the employee may be scheduled to retake the course at a later date. The scores are recorded as a Pass/Fail and entered into the company’s employee information system. Each student’s records are maintained in the database for future reference.

Response To Training

Feedback is critical to assess the direction of training and to make necessary changes. At the conclusion of each day’s instruction, the students should evaluate the instructor(s) on such items as communication ability, qualifications, course content and materials. They are encouraged to discuss the training with their supervisor once they return to their field location. The supervisor notifies the training committee if a change is requested. The committee takes all requests under advisement at their next meeting. Those suggestions lead to improvement of the training program and enhance the quest for excellence in the overall instructional skill and methodologies.

Author

Allen N. Chandler is senior instructor at Atmos Energy’s Charles K. Vaughan Center in Plano, TX, regarded as the natural gas industry’s leading technical training facility. Chandler has been involved in technical training on natural gas for more than 20 years. (See February 2012 P&GJ for more information on the Vaughan Center).

Comments