March 2012, Vol. 239 No. 3

Features

Moving Forward In Damage-resistant Coating Technology

Today, the use of a durable external coating system in combination with cathodic protection is well-accepted as the most effective means of corrosion prevention for oil and gas pipelines.

Many factors go into the coating selection decision including cost, damage resistance, pipeline terrain, backfill, soil conditions, joint coating solutions, quality assurance, logistics, electrical-resistance stability, non-shielding – CP, pipeline operating temperature, stress-corrosion cracking, and lifetime cost among others. This article will review some of the most common coating solutions used in the market today to provide resistance to damage during transportation and installation.

Single Layer FBE (1LFBE)

Fusion bonded epoxy is a one-part powdered epoxy coating that is sprayed onto the hot pipe where it melts, flows and cures to give a corrosion resistant coating. The first pipe coated with FBE was placed into service in 1960. FBE is now the most commonly used pipeline coating in North America for new installations. There are a number of properties that make it a good choice for many pipeline installations: 1) Excellent adhesion to steel; 2) good chemical resistance; 3) non-shielding to CP – fails friendly; 4) no reported cases of stress-corrosion cracking (SCC) of pipe coated with FBE; 5) installation friendly; 6) excellent penetration resistance, good abrasion and gouge resistance; 7) good impact resistance (impact damage is limited to the point of contact, damage is easily seen and damage is easily repaired); and 8) good flexibility.

As with all the coatings systems that will be discussed in this article, improper surface preparation, improper cleaning or a contaminated substrate can result in a loss of bond and/or blistering. However, FBE does not shield cathodic protection current so even with adhesion loss, the pipe can still be protected by CP. The major concern with the use of 1LFBE is transportation and handling damage. This is especially important in countries with inadequate infrastructure and long haulage routes to pipeline installation sites. Any damage that does occur can be easily repaired by application of a liquid epoxy resin. The thickness of the coating can be increased to help provide added absorption of impact and abrasion; however, as the thickness of the coating increases, the flexibility performance decreases.

Dual Layer FBE (2LFBE)

The use of two layers of fusion bonded epoxy can significantly improve damage resistance in comparison with 1LFBE. The first layer allows the system to retain the properties of a standalone FBE coating while the top layer can provide additional mechanical damage resistance from impact or gouging during handling, transportation, and construction. The first abrasion resistant outer (ARO) coating for directional drill pipeline installation was introduced in 1998. In 2002, the first major pipeline was coated with a dual layer coating system from end to end, including the girth welds. 2LFBE has since been used on multiple projects in India and Australia. Formulation design allowing for improved gouge and impact resistance typically result in a slight reduction in flexibility. This reduction in flexibility can have a negative influence for use in reel barge or cold-weather installation.

Three Layer Polyolefin (3LPO)

The use of three layer polyolefin coatings for protection of pipelines was introduced in Europe around 1980. These coating systems comprise: 1) epoxy primer coating (can be FBE or two-part Liquid epoxy); 2) Polyolefin-adhesive (or tie) layer (can be either an acid copolymer or grafted polyolefin); and 3) Polyolefin topcoat (can be either polyethylene or polypropylene).

In some applications, such as off-shore installations, additional layers are added to provide thermal insulation, provide additional weight or introduce a frictional surface.

The epoxy primer is the foundation of the system. Proper selection and application of the epoxy primer is crucial to overall performance of the system. Many things should be considered during the selection process including: 1) projected operating temperature, 2) humidity of the environment, 3) permeability of corrosive species, and 4) adhesion performance. As previously mentioned, for any coating system excellent surface preparation is crucial to overall coating performance.

The adhesive or tie layer provides a means of bonding the epoxy primer layer to the polyolefin topcoat. The first adhesives used for this application were copolymers of polyethylene or polypropylene co-reacted with functional groups such as acetates, acrylates, or organic anhydrides. Further developments in the field led to the introduction of maleic-anhydride grafted adhesives.

The polyolefin topcoat provides mechanical protection and reduces coating damage. It also slows the ingress of water to the FBE layer and the substrate below due to its excellent barrier properties. There are many types of polyolefin materials that are available including low-density polyethylene (LDPE), linear-low density polyethylene (LLDPE), medium-density polyethylene (MDPE), high-density polyethylene (HDPE), bimodal HDPE, and polypropylene.

3LPO systems are well-accepted and are regarded as the coating of choice by many in the industry when damage resistance is required. Unfortunately, going back to 2001, there have been numerous concerns expressed with three-layer coatings in service today. Problems and concerns that have been reported include: 1) potential for SCC, 2) cracking and splitting of the polyolefin coating (loss of bond between FBE and steel and adhesive and FBE), 3) adhesion failure and corrosion at the girth weld area, 4) loss of bond between FBE and steel layer, 5) shielding from CP and potential corrosion, and 6) disbonding at cutback.

Improved Dual Layer FBE System

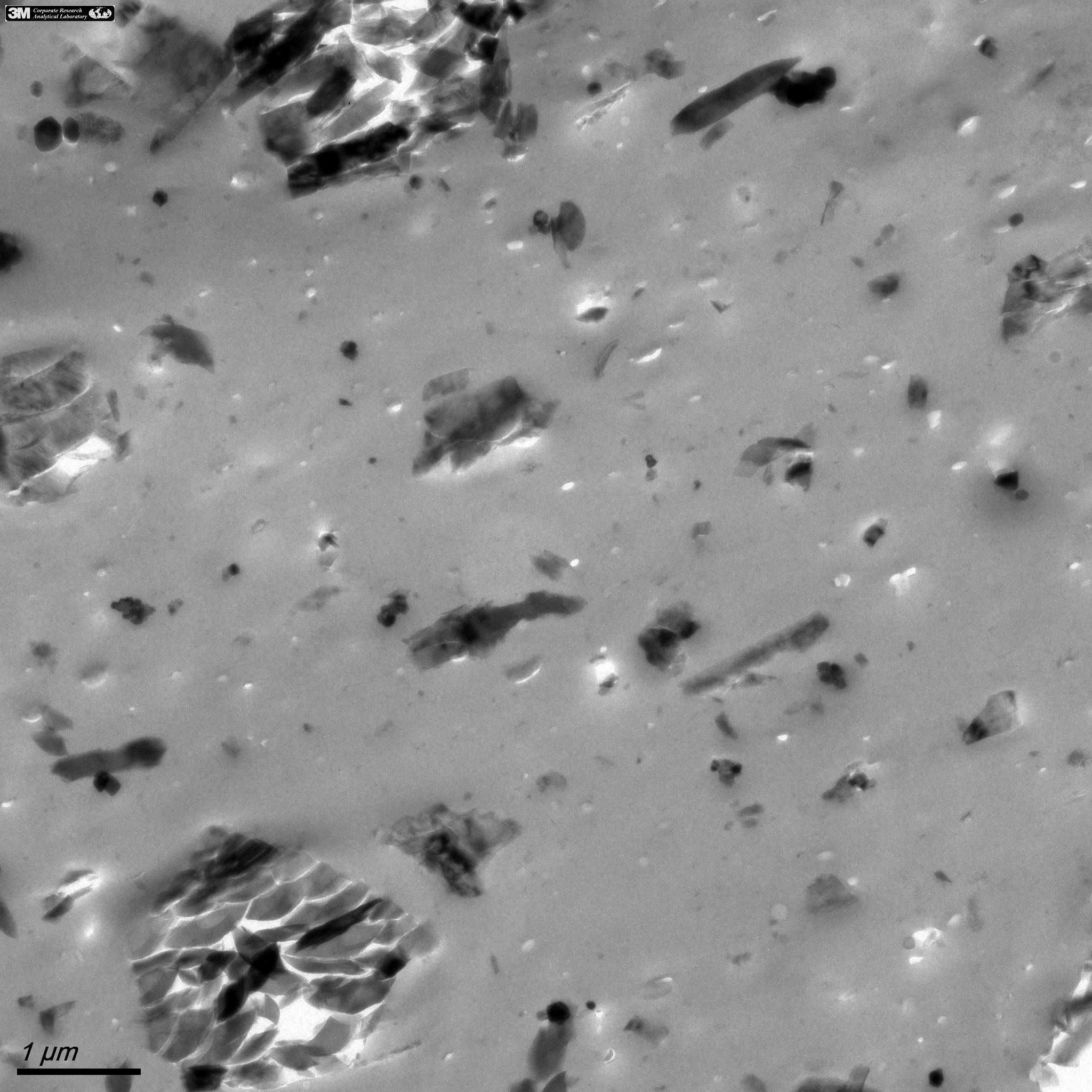

Typical 2LFBE systems applied at a thickness appropriate to provide proper damage resistance have flexibility ranges between 1.5°/PD and 2.5°/PD depending on the application conditions. A new concept first published in 2008 addresses this compromise between damage resistance and flexibility by providing a 2LFBE system that creates a unique morphology within the coating that limits crack propagation. The differences in morphology are observed at the microscopic level. A micrograph of a standard 2LFBE system is shown in Figure 1 while a micrograph of the flexible 2LFBE system is shown in Figure 2. The flexible 2LFBE system has cold temperature flexibility close to that of a 1LFBE even at high thickness without sacrificing impact and gouge resistance.

This improved 2LFBE coating system has the ability to reach 4°/PD at negative 30°C and 3°/PD at negative 50°C even at a total thickness of 50 mils. Figure 3 illustrates the difference in performance between the standard 2LFBE and the flexible 2LFBE. Both samples in the photo were coated at a total thickness of 30 mils under the same conditions and both were bent at 4°/PD at negative 30°C. The bar at the bottom of the photo was coated with the flexible 2LFBE system while the bar on the top was coated with a standard 2LFBE product. A more flexible 2LFBE system gives pipeline end users another solution to protect their pipeline in adverse geotechnical and service conditions.

Figure 1: Micrograph of a traditional 2LFBE coating at 10,000X.

Figure 2: Micrograph of the more flexible 2LFBE at 10,000X.

Figure 3: Steel samples shown in this photo were coated with a 2LFBE system, the top with a standard 2LFBE and the bottom with the newly developed more flexible 2LFBE. Both samples were cooled to negative 30°C and bent at 4°/PD.

Details regarding experiments conducted to evaluate the performance of this flexible 2LFBE system in comparison with standard 2LFBE systems were presented at NACE International’s CORROSION 2011 Conference & Expo and are available from the authors upon request. These experiments show that while there is a significant increase in the flexibility of this new coating system, the impact energy and gouge resistance are comparable to standard 2LFBE systems that are commercially available today.

Conclusions

There is a need in the market place for FBE coatings that are more resistant to mechanical damage during handling and installation of pipe. One approach to provide more resistance to mechanical damage is to increase the thickness of the overall coating. However, as the thickness of the coating increases, the coating has a greater tendency to crack under impact. Another conventional approach is to use dual layer fusion bonded epoxy coatings (2LFBE) with an abrasion resistant overcoat (ARO) having higher filler loadings to increase the damage resistance of the coatings. However, higher filler loadings can dramatically decrease the flexibility of the FBE coating. Thus, damage resistant dual layer coatings currently available require a compromise between toughness and flexibility.

This article introduces a new improved dual layer coating with cold temperature flexibility close to that of a single layer FBE even at high thickness without sacrificing impact and gouge resistance. This new flexible 2LFBE system has the ability to reach 4°/PD at negative 30°C and 3°/PD at negative 50°C even at a thickness of 50 mils. Gouge and impact resistance performance are equivalent to a standard 2LFBE system. This improved dual-layer coating gives the pipeline end user another solution to protect their pipeline in difficult geological conditions.

ACKNOWLEDGEMENTS

This article was based on a presentation given at NACE International’s CORROSION 2011 Conference & Expo in Houston (Paper No. 11031). A full copy of the presentation, with additional text, illustrations and references, is available. The authors would like to give special thanks to Susan Wieland, Stephen Daniell and Brenna Sura for their help in generating the data presented.

Author note: The experiments referenced in this article were conducted by researchers at 3M in both Austin, TX and St. Paul, MN. The test methodology and test results described in this report are, to the best of our knowledge, accurate. 3M makes no representations or warranties regarding the test methodology or the test data itself. As a matter of customer service, 3M will work with customers to resolve any related challenges encountered in the future. Ultimately it is the responsibility of the customer to determine whether or not additional testing is required and whether or not the final product is suitable for use in the customer’s specific application(s).

Authors

Dr. Jennifer Pratt is working in product development in 3M’s Infrastructure Protection Division. Her area of research is in FBE coatings used in multiple market segments including O&G. She has a doctoral degree in organic chemistry from the University of Illinois.

Dr. Andrew D’Souza is working in R&D in 3M’s Safety Security and Protection Services Lab. His areas of research are in FBE coatings and inorganic stay clean coatings. He has a doctoral degree in materials science and engineering from the Pennsylvania State University.

Meghan Mallozzi obtained a BS degree in chemical engineering from the University of Colorado, Boulder and a MBA at the University of Texas, Austin. She joined 3M in 2004 with the Corrosion Protection Products Division as a Product Development Engineer with a focus in the areas of nano-composite chemistry and epoxy/polyolefin interpenetrating coatings.

Comments