September 2011, Vol. 238 No. 9

Features

Gas Turbine Compressor Blade Fouling Mechanisms

Fouling of compressor blades is an important mechanism leading to performance deterioration in gas turbines over time. Fouling is caused by the adherence of particles to airfoils and annulus surfaces. Particles that cause fouling are typically smaller than 2 to 10 ?m.

Compressor fouling is due to the size, amount, and chemical nature of the aerosols in the inlet air flow, dust, insects, organic matter such as seeds from trees, rust or scale from the inlet ductwork, carryover from a media type evaporative cooler, deposits from dissolved solids in a water spray inlet cooling system, oil from leaky compressor bearing seals, ingestion of the stack gas or plumes from nearby cooling towers.

Fouling must be distinguished from erosion, the abrasive removal of material from the flow path by hard particles impinging on flow surfaces. These particles typically have to be larger than 10?m in diameter to cause erosion by impact. Erosion is probably more a problem for aero engine applications, because state-of- the-art filtration systems used for industrial applications will typically eliminate the bulk of the larger particles. Erosion can become a problem for engines using water droplets for inlet cooling or water washing.

Deterioration due to fouling is usually reversible, as the particles can be removed through compressor washing.(1) This distinction is important, because the economic implications of recoverable and non-recoverable degradation have different economic impacts.

Fouling can be removed by off line water washing and slowed down by online water washing. Theoretically, the engine can be kept at a very small degradation level at all times, if it is frequently washed on-line, and the cost (i.e. lost production) of shutting the engine down for off-line washing (typically a half day) is carried. The decision to shut the engine down for off-line washing is a balance between lost production due to the lower power vs. the lost production for shutting the engine down for a certain amount of time. The reversal of non-recoverable degradation requires the engine to be overhauled. Therefore, operators likely will allow much larger levels of non-recoverable degradation before they take action.

In this article, we will not address the other, more permanent consequence of particle ingestion that is the potential for hot corrosion as a result of salt particles entering the engine and reacting with sulfur from fuel or combustion air.

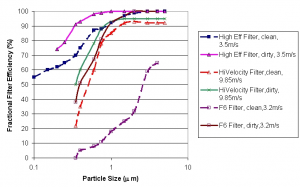

Industrial gas turbines can afford very effective inlet filtration systems. Modern systems can virtually eliminate the ingestion of particles into the engine compressor that can cause erosion (Figure 1). The trade-off for filtration systems lies in size, weight and cost on one side vs. filtration efficiency vs. low pressure loss as well as dust holding capacity. (3)

Figure 1: Comparison of fractional efficiency for filter elements from different suppliers and different face velocities in new and dirty conditions.(4)

Schroth et al.5 report on a comparison of GT power loss for two different air filtration systems used on 165MW gas turbines. The filtration systems are either a 2-stage or a 3-stage system. The 3-stage system causes a significant reduction in finer particles entering the engine. Power loss after 3,000 hours of operation was 4% with the 2-stage system and 2% with the 3-stage system.

Say an engine ingests 100 kg/year of contaminants where there is no filtration system. Per EN 779, in a typical off shore application, an F5 filter would reduce this to about 21 kg/year, an F6 filter to 6 kg/year, an F7/H10 filter system to 0.2 kg/year and an F7/F9/H10 system to as little as 0.05 kg/year. This shows that the overall contaminant ingestion can be influenced by several orders of magnitude by using an appropriate air filtration system. Also, with filtration systems of this type, there are virtually no particles larger than a few microns entering the engine.

Figure 2 shows typical salt deposits on the compressor of a gas turbine in offshore service. The deposits are fairly uniform, and exist on both suction and pressure side of the rotor blades. It must be noted that not only the compressor blades and guide vanes are subject to fouling, but also the casing. The fouling of casings is due to the centrifuge action of the swirling airflow through the compressor. This means in particular, that larger particles hit the walls at earlier stages and more frequently, while smaller particles will come into contact with the walls farther downstream.

Whether particles that come into contact with the blade surface attach themselves depends on two factors: 1) the “stickiness” of the surface relative to the particle and 2) the shear forces in the boundary layer.

The “stickiness” of the surface is increased if the surface is wet (from water or oil), but it also depends on particle size (particles above about 10?m in diameter tend not to stick), and the angle of impact on the surface. The shear forces in the boundary layer are low in areas of laminar flow, and particularly low in areas where the flow separates or transitions from laminar to turbulent flow.

The state of the boundary layer is highly sensitive to the operating point of the compressor blade. The sticking forces of very small particles are very high even without the presence of oils or other liquids on the blade surface. The presence of oil or liquid films on the blades will, however, increase the particle size that still can stick to blades even in the presence of high shear or centrifugal forces.

The effects for liquid particles are different from solids. In particular, the higher the impact velocity of the droplet, the higher the chances are that the liquid remains on the surface. Hydrophobic surfaces (e.g. oil- covered) increase the chances of particles to bounce off the surface after initial contact. In general, the mechanisms include van der Waals, capillary, and electrostatic forces, and re-entrainment.

The forces get more dominant for smaller particles. If there is wetness, capillary forces tend to dominate. The probability of a particle sticking to a surface increases the lower the viscosity of the particle becomes. This leads to the following: 1) dry particles have to be very small to stick, and 2) wet surface and/or wet particles allow bigger particles to stick.

It must be noted that wet particles (for example water droplets) will dry out as they pass though the compressor, and therefore have reduced “stickiness” when they pass through the rear compressor stages. Of importance is that the design of a gas turbine compressor has very little impact on the capability of particles to stick to surfaces once they reach them.

A number of researchers have tried to determine the susceptibility and sensitivity of different gas turbine designs and sizes. Susceptibility is the amount of fouling a compressor incurs under a specified contaminant load, while sensitivity describes the effect on compressor efficiency, or, in a wider sense gas turbine power output capability and efficiency, of a certain amount of compressor fouling. Meher-Homji et al.2 studied a wide range of 92 gas turbines to evaluate their sensitivity to an imposed level of fouling. Key results indicate that the net work ratio (Net work ratio = GT work output/ work from turbine) is a good predictor of both the gas turbine’s susceptibility to foul and its sensitivity to fouling. Low net work ratio engines where a higher portion of the total turbine work is consumed in the compressor tend to be both more susceptible and sensitive to axial compressor fouling.2 This is basically due to the fact that, for a given loss of compressor efficiency, the impact on power output is larger for a low NWR engine.

In order to assess the nature of the problem, a number of experimental data sets were evaluated. Some of them are from literature references 6-8, and some are from our own tests (Figure 3). The analysis shows the degradation rate of engines between on-crank washes, which is mostly due to fouling. The important finding is that neither engine size nor type has a real influence on degradation rate. In particular, the two-shaft engine (two-shaft engines show a higher sensitivity to fouling1) did not behave any worse than the single-shaft engines.

Figure 3: Fouling Rates (Power Degradation) for different gas turbines. Engines 26, 37, and 48 are all larger than engines 1 and 59. Engines 1, 2, 4 and 5 are single-shaft engines. Engine 3 is a two-shaft engine.

Conclusions

Based on theoretical considerations, as well as observed engine fouling behavior, a few items can be observed regarding engine fouling. It needs to be emphasized that this only pertains to engine fouling. Engine degradation due to erosion and corrosion is subject to other mechanisms, either separate or in conjunction with fouling mechanisms. The few items observed:

1) Fouling is caused by particle sizes of 10 micrometers and below. Air filtration systems for industrial gas turbines are very effective for particle sizes about 5 micrometers and above, but, depending on the types of filter systems, allow ingestion of particles below that size. In typical operating environments, particles of various sizes, including sub-micron sized particles, are present.

2) The capability of particles to stay at a surface is dependent on particle size and the wetness of the particle or the surface. In particular, larger particles will likely not stay attached to a surface, unless the particle or the surface is wet.

As far as the susceptibility of engines to fouling, a few additional observations are to be made:

1) The quality of the air filtration system is probably the dominant factor in engine fouling, as it determines particle size, particle count and presence of wet particles.

2) Ambient conditions (especially the presence of high humidity conditions or the presence of wet contaminants) are the other dominant factor, since this determines the chance of particles sticking to the blades.

This means, in particular, that simple factors that rate the fouling susceptibility of engines, and that are based on the chance of particles to impact the blade surface, do not take some of the most important influence factors into account. In other words, ambient conditions and the quality of air filtration systems have a far greater impact on fouling rates than engine-specific fouling susceptibility factors. Contact information for further information: e-mail: saeid_mokhatab@hotmail.com.

References

1 Kurz, R., Brun, K., and Wollie, M., “Degradation Effects on Industrial Gas Turbines”, Trans. ASME J. Eng. Gas Turbines Power, 131, 6, 62401 (2009).

2 Meher-Homji, C.B., Chaker, M., and Bromley, A.F., “The Fouling of Axial Flow Compressors – Causes, Effects, Susceptibility and Sensitivity”, ASME GT2009-59239 (2009).

3 Wilcox, M., Baldwin, R., Garcia-Hernandez, A., and Brun, K., “Guideline for Gas Turbine Inlet Air Filtration Systems”, Gas Machinery Research Council, Dallas, TX, USA (2010).

4 Brekke, O., and Bakken, L.E., “Performance Deterioration of Intake Air Filters for Gas Turbines in Offshore Installations”, ASME GT2010-22454 (2010).

5 Schroth, T., Rothmann, A., and Schmitt, D., “Nutzwert eines dreistufigen Luftfiltersystems mit innovativer Technoloie fuer stationaere Gasturbinen”, VGB Powertech, 87, 48-51 (2007).

6 Haub, G.L., and Hauhe, W.E., “Field Evaluation of On-Line Compressor Cleaning in Heavy Duty Industrial Gas Turbines”, ASME 90-GT-107 (1990).

7 Veer, T., Haglerod, K.K., and Bolland, O., “Measured Data Correction for Improved Fouling and Degradation Analysis of Offshore Gas Turbines”, ASME GT2004-53760 (2004).

8 Schneider, E., Demircioglu, S., Franco, S., and Therkorn, D., “Analysis of Compressor On-Line Washing to Optimize Gas Turbine Power Plant Performance”, ASME GT2009-59356 (2009).

9 Kurz, R., and Brun, K., “Fouling Mechanisms in Axial Compressors”, ASME GT2011-45012 (2011).

Comments