October 2011, Vol. 238 No. 10

TechNotes

Record-setting AUV Pipeline Inspection In Norway

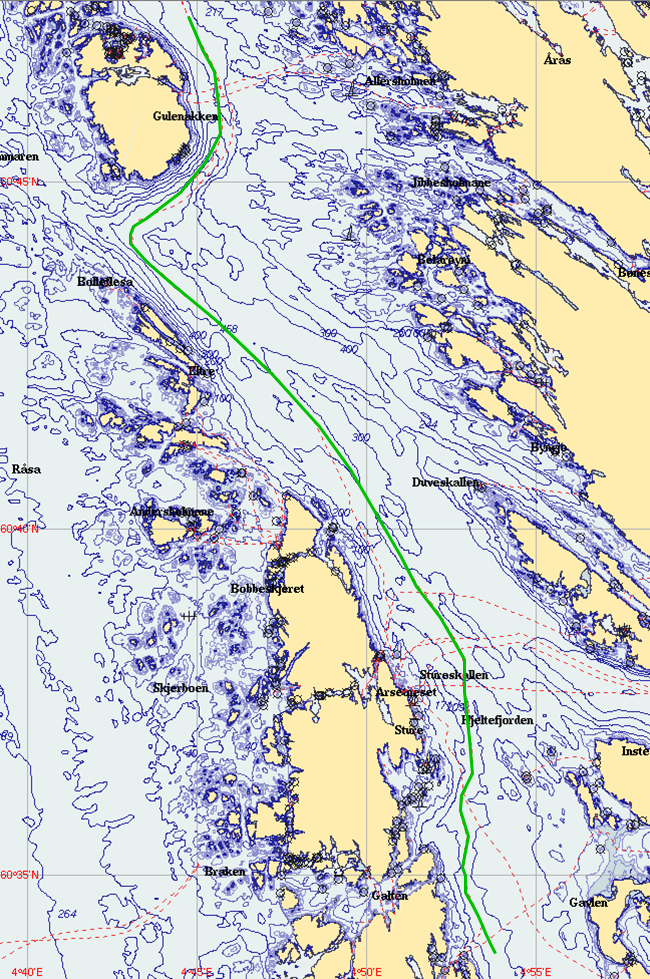

Kongsberg Maritime completed the world’s longest, multi-sensor autonomous underwater vehicle (AUV) pipeline survey using one of its cutting-edge HUGIN 1000 AUVs. The inspection took place in February in the Hjelte fjord near Bergen, Norway. The HUGIN 1000 was operated from the Royal Norwegian Navy vessel HNoMS Måløy .

The subject of the inspection was two subsea pipelines going to the Mongstad oil refinery. The HUGIN 1000 AUV was equipped with an advanced suite of Kongsberg imaging equipment including the HISAS 1030 synthetic aperture sonar, EM3002 multibeam echo sounder and an optical camera with LED lighting. The instruments were used to inspect 30 km of subsea pipeline in an eight-hour, two-pass mission.

In the first pass, side-scan data from the HISAS 1030 sonar was used to detect and track the pipelines in real-time, using PipeTracker software for the pipeline detection and the tracking of extracted pipe-like features in the sonar images. This was accomplished with a high degree of robust false detection avoidance.

Figure 2: A single three-megapixel camera image. Altitude 4.6 m. Resolution 2×2 mm.

The PipeTracker software was developed in collaboration with the Norwegian Defence Research Establishment (FFI) funded by the Norwegian Research Council. It runs as a plug-in module in the standard HUGIN payload system. The HUGIN 1000 control system in turn uses the identified pipeline tracks to position the vehicle at an optimal range for HISAS imaging. The whole process is fully automated inside the AUV and requires no operator intervention.

In the second pass, HUGIN followed the pipeline tracks identified in the first pass at low altitude and inspected the pipelines using the EM 3002 multibeam and the optical camera.

Figure 3: HISAS image. Area 120×90 m. Range 32-152m. Resolution 35×35 mm.

After the mission, the recorded HISAS 1030 image data was post-processed into high-resolution (4×4 cm) sonar images and bathymetry maps of the pipeline. Together with the optical images and the multi-beam data recorded in the second pass, this provided a detailed view of the pipeline surroundings and the pipeline itself.

The complete procedure was repeated the next day over the second pipeline in a new eight-hour, two-pass mission.

Figure 4: Raw bathymetry from EM3002. Area shown 120×120 m.

Both pipelines were surveyed at a constant speed of four knots and at 4-25 m altitude, depending on the sensor in use. Water depth was 180-560 m. The greater speed of the HUGIN 1000 compared to that of a ROV meant that 60 km of pipeline could be inspected in a little over 16 hours during the two passes. The stability of the HUGIN platform and the ability to simultaneously operate both at high speed and at low altitude resulted in an efficient survey with crystal clear images from the onboard optical camera.

Kongsberg’s REMUS family of AUVs – built by its subsidiary Hydroid – can also perform visual pipeline inspections and pipeline surveys when equipped with high-frequency sidescan sonar, a multi-beam and camera. Hydroid’s REMUS 100 AUV, used for deployment in shallow waters, and the REMUS 600, used for operation in greater depths, boast the same capabilities as the HUGIN 1000, allowing the vehicles to succeed in pipeline inspections.

Authors:

Even Børhaug received his MSc and Ph.D. degrees in engineering cybernetics from the Norwegian University of Science and Technology in 2005 and 2008, respectively. He then joined Kongsberg Maritime where he works as an R&D engineer in the AUV software department with a special focus on the design of guidance, control and communication systems for the HUGIN AUV. E-mail: even.borhaug@kongsberg.com.

Per Espen Hagen received his MSc degree in signal processing from the Norwegian Institute of Technology in 1989. He then joined the Norwegian Defence Research Establishment (FFI). From 1999, he was project manager for FFI’s AUV and SAS related research. In 2008, he joined Kongsberg Maritime, where he is in charge of system architecture in the AUV R&D Department. E-mail: per.espen.hagen@kongsberg.com.

Comments