February 2011, Vol. 238 No. 2

Features

Advanced Pipeline Welding Technologies Boost Productivity

For years pipelines have been constructed by manual welders using conventional arc welding processes and consumables. This approach is still used to construct small-diameter, low-pressure pipelines as well as tie-ins and repairs on larger diameter, high-pressure pipelines.

However, for larger diameter pipeline projects, there has been a shift away from manual arc welding to more automated arc welding systems, with multiple welding arcs. The automation aspect of these systems allows for better control of the welding parameters and a reduction in the total volume of weld metal required by moving away from conventional V-groove designs to narrower groove designs. Multiple welding arcs allow for the deposition of more than one pass per trip around the pipe, dramatically reducing the time required to complete the weld.

Recent research has been focused on alternatives to arc welding while still maintaining, at a minimum, the same level of productivity. Two welding processes have shown promise as alternatives to arc welding while being able to increase productivity. The two welding processes are Hybrid Laser Arc Welding (HLAW) and Friction Stir Welding (FSW). Historically these welding processes had limited portability so they had been restricted to the laboratory. However, recent advancements have allowed these processes to move out of the laboratory and into the field.

The HLAW process is a combination of laser beam welding and arc welding in the same weld pool (Figure 1). HLAW has been used with a variety of lasers (e.g. CO2, Nd:YAG, fiber, and disk) and arc welding processes (e.g., gas tungsten arc welding and gas metal arc welding), with the most common arc welding process being pulsed gas metal arc welding.

The HLAW process takes advantage of the high energy density of the laser beam while benefiting from the alloying and fit-up tolerances of the arc welding process. One application for HLAW is deep penetration, single-pass welds in thick material which increases productivity by reducing the total number of weld passes needed to fill a joint. It also significantly reduces the heat-input as compared to conventional arc welding processes.

Another application for HLAW is high-speed welding using the laser beam to stabilize the weld pool. The weld pool stabilization prevents weld humping at high speeds and improves side-wall fusion in groove welds. This application of HLAW boosts productivity by increasing the maximum travel speed that can be achieved by arc welding alone.

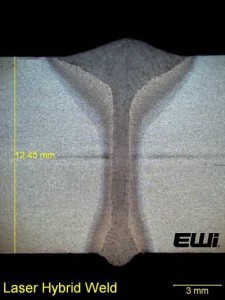

HLAW has been used on a wide variety of materials and thicknesses. For butt joints, the amount of laser power dictates the depth of penetration that can be obtained in a single pass. Generally speaking, 0.040 inch (1 mm) of penetration is obtained per kilowatt of laser power at typical HLAW travel speeds. For example a 1.1-inch (28-mm) full-penetration weld has been deposited using 30 kW of laser power. Figure 2 shows a full-penetration, single-pass HLAW weld using 10 kW of laser power.

HLAW has been considered a laboratory or factory-welding process due to laser equipment limitations (i.e., size and cooling requirements). With the recent advancements of high-power, solid-state lasers (e.g. disk and fiber) this perception has begun to erode. Disk and fiber lasers can provide more than 20 kW of laser power at a significantly higher electrical efficiency than their predecessors (approximately 25% wall-plug efficiency vs. approximately 5% for CO2 and Nd:YAG lasers). This improved electrical efficiency has dramatically decreased the equipment size, making HLAW a more realistic alternative to arc welding of pipelines. A portable HLAW system has been developed and successfully demonstrated in a simulated field environment (Figure 3).

Friction Stir Welding is a solid-state process which relies on frictional heating and localized forging to join two pieces of material. The FSW weld is made by plunging a non-consumable, rotating tool into the base material which subsequently traverses a joint seam. The shoulder constrains the plasticized material while the pin stirs the interface to produce a fully consolidated weld. Advantages of this process include low distortion, no hazardous fumes, and welds with matching base material mechanical properties.

From the beginning, FSW targeted the joining of soft metals such as aluminum alloys where it has enjoyed considerable success in the automotive, aerospace and shipping industries, among others. The FSW process has been used to make welds in aluminum up to 3-inch (76.2-mm) thick in a single pass. In the past 10 years, FSW has seen considerable growth in the joining of hard metals such as steel, titanium and nickel alloys. These achievements are due to the development of new tool materials (e.g. PCBN, tungsten rhenium) and the advancements in tool design. The FSW process has deposited welds in steel up to 0.75-inch (19.1 mm) thick (Figure 4) and in titanium up to 1-inch (25.4-mm) thick in a single pass.

Most FSW machines are non-portable fixed installation machines (Figure 5). A few organizations have been able to produce portable FSW systems for applications which include pipeline construction. Existing FSW equipment has successfully been demonstrated on several different diameter pipes in both the 1G and 5G welding positions. FSW equipment research is looking into developing completely automated systems aiming for push-button functionality, equipment flexibility to weld different diameter pipes, and improved machine portability.

When new technology is developed, it takes time to become accepted by industry. This is especially true for the pipeline industry, which is heavily regulated by the government. The Code of Federal Regulations Title 49 Part 192 and Part 195 govern the design, construction, operation and maintenance of gas and liquid pipelines, respectively. Both Parts require that the welding procedure and welder be qualified to the American Petroleum Institute (API) Standard 1104, Welding of Pipelines and Related Facilities, or Section IX of the American Society of Mechanical Engineers (ASME) Boiler and Pressure Vessel Code. Neither API 1104 nor Section IX of ASME has qualification requirements for HLAW or FSW. ASME has recognized this deficiency and is developing qualification requirements for both processes.

Since the most common form of HLAW is a combination of GMAW and Laser Beam Welding (LBW), the proposed HLAW procedure qualification variables, as defined by ASME, are a combination of the applicable GMAW and laser-welding variables with a few additional variables specific to HLAW. Some HLAW specific variables include beam-to-wire spacing tolerances and process-orientation definitions (i.e. wire leading or laser leading).

FSW is a unique welding process that requires numerous variables specific to the process. The proposed FSW procedure qualification variables include those that are shared with other welding processes (joint variables, base metals variables, etc.) in addition to tool and equipment variables that are specific to FSW.

HLAW and FSW have been shown to improve productivity compared to typical arc welding processes. The increased productivity comes from either an increase in the maximum achievable travel speed or by increasing the single-pass weld thickness which reduces the total number of passes required to complete a pipeline girth weld. The HLAW process has been used to deposit an acceptable single-pass, full-penetration weld in carbon steel up to 3-inch (76.2-mm) thick and systems have been developed to take HLAW outside the laboratory on fixed position pipelines. The FSW process has been used to produce a full thickness, single-pass welds in 0.75-inch (19.1-mm) thick steel with portable machines being developed for field applications.

Although both welding processes have shown promise for field pipeline construction, more research and development is required. Prior to waiting for the industry to ask the questions, ASME is developing qualification requirements that can be used by the pipeline construction contractors interested in applying these new welding technologies. Hopefully, with the ASME guidance in place, the acceptance of either HLAW or FSW as an alternative to arc welding of large-diameter pipelines will be a smooth transition.

Authors

Matt Boring, P.E., has B.S. and M.S. degrees in welding engineering. He is a senior engineer at Edison Welding Institute (EWI) and has been with EWI for 14 years, employing his technical expertise in the areas of pipeline welding and in-service pipeline repair welding (hot-tap welding). He is a member of the API 1104 Appendix B committee, the ASME Post-Construction Subcommittee on Repair and Testing and a member of the ASME Section IX subcommittee on procedure and performance qualification.

Brian Thompson, B.S. and M.S. degrees in welding engineering, is an applications engineer in the Friction Stir Welding Technology Group at EWI. His area of expertise includes the friction stir welding process as applied to a variety of materials including but not limited to aluminum, magnesium, copper, steel, titanium, and nickel alloys. He also has experience in using different variations on the friction stir welding process such as Friction Stir Spot Welding and Friction Stir Processing. Other welding and joining technologies with which he has experience include resistance spot welding, inertia welding, and projection welding.

Brad Nagy, B.S. degree in welding engineering, is an applications engineer at EWI. Prior to joining EWI, he spent three years with John Deere and three years with Honda of America. While at John Deere, he was involved with the design and implementation of multiple robotic welding cells used for joining utility vehicle frames. More recently, Brad was involved with the Supplier Development department at Honda of America. During his time with Honda, Brad worked with Tier 1 and Tier 2 automotive suppliers on process improvements and the implementation of Lean Manufacturing principles. At EWI, he has been heavily involved in development of the Hybrid Laser-GMAW (HLAW) process.

Comments