November 2010 Vol. 237 No. 11

What's New

Whats New In Valves And Valve Operators

Valves and valve operators from Cameron Valves & Management, Flowserve Corp., Dresser, Inc., US Valve Services and Training, Rupture Pin Technology, AnTech Ltd., R.W. Lyall and Polytec Co., Dresser’s Mooney, Flowserve Nordstrom, Leser, LLC, Siemens, Specialty Maintenance Products and CECO.

Cameron Valves & Measurement

Cameron’s Valves & Measurement offers a digital brochure devoted to its distributed valves line. The distributed valves division provides products sold through distributor networks worldwide. The offering includes such widely recognized brand names as DEMCO® (butterfly and gate valves), NAVCO® (butterfly valves), NUTRON® (TT and B3 ball valves), TECHNO® (check valves), THORNHILL CRAVER®, TOM WHEATLEY™ (piston check valves), WHEATLEY® (check valves) and WKM® (butterfly valves and 310 and 370 ball valves). 800-323-9160, www.c-a-m.com.

Flowserve Corp.

Flowserve, provider of flow control products and services, recently announced the certification of the Flowserve Valtek Mark Series family of control valves and actuators to Safety Integrity Level (SIL) 3. The company said the SIL certification, which is a measurement of the effectiveness of a safety system, extends to valves and actuators built in Flowserve’s Springville, UT and Bangalore, India facilities. In obtaining the SIL 3 certification, the company said it partnered with exida, a global supplier of functional safety products, services and certifications, which has performed more process control safety certifications than any other company worldwide. www.flowserve.com.

Dresser, Inc.

Dresser says its Becker T-Ball control valves will play a role in efforts to “green” the 2014 Olympic Winter Games in Sochi, Russia. Becker T-Ball control valves, model QTCV-T1, have been selected by Gazprom for the “city gate” natural gas feed station for the Olympic Village. The Becker valves are said to have a unique combination of proven technology and environmentally friendly characteristics that made them the only acceptable solution for the feed station’s needs. The below-ground Becker regulator technology is said to have been viewed as ideally suited to this installation because of its sound attenuation capabilities, low maintenance design and tight emission controls. The non-clogging, low-maintenance design allows for below-ground installation which, in turn, provides sound attenuation. http://www.dresser.com/index.cfm/go/product-detail/product/QTCV-T1/.

US Valve Services and Training

US Valve Services and Training’s website says it offers the finest valve and actuator service work as well as the most popular hands-on training courses in the pipeline and oil and gas industry. The site provides a list of services offered: actuator installation, valve and actuator troubleshooting, valve and actuator rebuilding of all types, gear box maintenance and repair, specialized valve and actuator training, routine valve maintenance, free seized or hard to operate valves, perform emergency valve sealing, commissioning of newly installed valves, valve maintenance products and high pressure grease gun repair.800-270-8250, e-mail: sales@usvalveservices.com, training@usvalveservices.com.

Rupture Pin Technology

Rupture Pin Technology offers a digital brochure focusing on its advanced relief valve technology. The brochure says “for over 22 years, many of the world’s top companies have experienced the performance advantages of our advanced relief valve technology. These companies have come to trust our technology because they understand what uniquely sets us apart…” The brochure explains that what sets it apart is the company’s rupture pin which is the heart of each relief valve produced. “The pin is vital to the function, accuracy and consistency of the valve. By modifying the pin, we are able to control the valve’s performance – from small changes to more dramatic changes. It is for this reason that each pin is carefully crafted using a precise manufacturing process. This process ensures that each valve will perform its function accurately, consistently and within an extremely tight tolerance.” www.rupturepin.com, 405-789-1884, sales@rupturepin.com.

AnTech Ltd.

AnTech Ltd. of Exeter, England, is using a R&D grant to produce a prototype of what the firm terms a revolutionary new directional drilling tool called the Polaris. The tool is described as the first of its kind to use a solid state gyro for directional drilling. Until now, the firm says using a solid state gyro to monitor orientation while drilling has not been possible. With AnTech’s proprietary Polaris solution and patented methods, it is now a reality that offers a simple, low-cost solution. AnTech says although this technological breakthrough will offer solutions for a wide range of applications, its initial focus is on the coiled tubing directional drilling market. In the picture of the Polaris team is (second from left) Toni Miszewski, founder and managing director. 44 1392 440 300, Email: tonim@antech.co.uk, www.antech.co.uk.

R.W. Lyall and Polytec Co.

R.W. Lyall & Company offers a digital brochure devoted to the full line of PE ball valves from Lyall and Polytec Co., Ltd., for North America. The Lyall-Polytec gas applications polyethylene ball valves brochure says the two companies have teamed to provide a full line of medium- and high-density PE ball valves in a “full range of high quality residential and industrial PE ball valves sizes ½ CTS through 16 IPS. The gas applications valves meet or exceed ASTM D 2513, ASME B16.40, CFR 49, Part 192 and CSA B137.4. 800-535-9255, www.rwlyall.com.

Dresser’s Mooney

Dresser’s Mooney® has expanded its Slam Shut™ Valve line to include a 1-inch linear plug design and rotary design sizes to 4 inches. The 2-, 3- and 4-inch sizes can be integrated into a Flowgrid® Regulator or can stand alone. The Mooney Slam Shut Valve is a unique pneumatically actuated device that provides accurate over and/or under downstream pressure protection. Its patent-pending design guarantees a snap-acting release of the latch only when designated set points are exceeded. This eliminates costly “accidental shutoffs” from vibration or conditions other than over/under pressures. A positive shutoff is achieved instantly with zero pressure differential requirements and an easy reset can be completed with common hand tools. The Mooney Slam Shut is described as an ideal solution to provide reliable and safe downstream protection. www.dresser.com.

Flowserve Nordstrom

According to the Flowserve website, the Flowserve Nordstrom Dynamic Balance valve is the premier Nordstrom plug valve for crude oil pipelines and other applications which incorporates proven features and user benefits from over 60 years of experience. A pressure-balanced plug assures predictable torque even under high-pressure differential, vibration and thermal cycling. Pressure-energized stem seals eliminate external adjustments and the stem and cover weather seal provides superior corrosion resistance in hostile environments. The Dynamic Balance plug valve is available in the broadest range of sizes, pressure classes, and materials of construction of any Nordstrom Audco product. Dynamic Balance valves are available in sizes from 1 to 30 in ANSI pressure classes from 150 to 2500, and in sizes 2-1/16 to 4-1/16 in API pressure classes 3000 and 5000. www.flowserve.com.

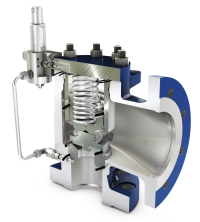

Leser, LLC

Leser has introduced a new pilot-operated safety valve series. Both pop-action (Series 810) and modulate-action valves (Series 820) are included. The typical application areas of the pilot-operated safety valve (POSV) are refineries and gas-processing plants, compressors in gas pipeline systems and offshore applications. The own-media-controlled POSV offers the advantage that the plant can be run close to the set pressure of the valve. POSVs are said to allow higher external back pressures than spring-loaded safety valves. As a special design feature, Leser says the tubing between the pilot valve and the main valve is integrated in the main valve cover, reducing the risk of damage or freezing. The backflow preventer is included as standard. 704-587-3670, email: salesus @leser. com, www.leser.com.

Siemens

Siemens says the SITRANS FUG1010 clamp-on non-intrusive ultrasonic flowmeter is ideal for natural and process gas applications, including check metering, allocation, production, storage and gas-fired power station applications. The flowmeter is available in single, dual and optional four-beam configurations, with the buyer’s choice of IP65 (NEMA 4X) or IP65 (NEMA 7) and IP66 (NEMA 7) explosion proof enclosures. Benefits cited include easy installation – no need to cut pipe or stop flow; minimal maintenance – external transducers do not require periodic cleaning; no moving parts to foul or wear; eliminates the pressure drop or energy loss in orifice metering; wide turn-down ratio; choice of single, dual or optional four-beam versions; single-beam version reduces initial investment. 800-743-6367, www.usa.siemens.com/pi

Specialty Maintenance Products

The Valve-Out Tool from Specialty Maintenance Products is described as allowing you to safely and efficiently remove or install flanged valves, regulators, meters or spools without the use of come-alongs or hammers and wedges. It is for use on flanges from 3/4-inch to 1-3/8-inch bolt-holes. Demonstration video is at 713-667-4402, info@flangespreaders.com, www.flangespreaders.com.

CECO

CECO says its rMAX™ valve (patent pending) is becoming the replacement valve of choice for operators of high-speed compressors who are looking for a longer valve life while matching the flow of plate valves. The company says the valve will run much longer than conventional plate valves, especially in “dirty” or “wet gas” applications. When the valve was in development, CECO says CenterPoint Energy contacted CECO about an unusually high valve failure rate at one of CenterPoint’s compressor stations. Contaminates in the gas stream were causing station hands to replace or repair valves frequently – sometimes every one or two weeks. CECO engineers suggested the rMAX™ valves. Now, two years later, the rMAX high-speed poppet valves are “still going strong,” CenterPoint’s Brad Goodwin said. www. TRYCECO.com.

Comments