February 2010 Vol. 237 No. 2

Features

Video Pipeline Monitoring Offers A Tool To Avoid Costly Losses

We’ve heard of CPM, or computational pipeline monitoring. Isn’t it time that we embrace the opportunities of VPM: video pipeline monitoring? For years, pipelines have relied on traditional equipment for monitoring; that is, basic instrumentation brought back to the control room via some networking method.

Most control rooms contain a SCADA system that provides significantly enhanced control, analysis and operational integrity by using sensor-based data and feeding it in some form to human operators. The scope of supervisory control has expanded to include computational pipeline monitoring: the ability to detect leaks in the system, as well as help plan for predictive maintenance.

Yet a report by the National Transportation Safety Board, the agency that oversees pipeline operations, suggests that our conventional approach to pipeline instrumentation and control has left significant gaps that cost time, money and product. These gaps include:

- Errors due to cluttered data displays, causing operator confusion or misinformation.

- Errors due to nuisance alarms, unprioritized alarms, or flurries of alarms, leading to slow or omitted response to field conditions.

- Errors related to lack of training of controllers responsible for pipeline and SCADA system operation.

- Property damage, product loss and equipment loss due to vandalism and other trespass at pipeline facilities including compressor stations.

Improvements in various hardware and software technologies are enabling more choices in the instrumentation that can be put in the field and tied back to the control room. However, instrumentation usually just senses and delivers data; it must be converted into usable information by a trained controller or by other systems. Making better decisions faster requires more data, integrated into forms that enable faster decisions.

Video delivers ready-to-use information, in the form of still and moving pictures, to help controllers make better decisions faster. Thus, video helps address the operational gaps in efficient and cost-effective ways.

One way to train operators is to observe and critique their actions during a pipeline alarm or incident. Modern video and historian tools allow engineers and operators to “go back in time” to view what happened, and what actions the operator took at the HMI during the incident. The photo in Figure 1 shows a Wonderware ActiveFactory screen (center left), with historical data on the top and video from the plant floor on the bottom. The center right screen shows a video recording of the HMI screen, and what actions the operator took during the incident. With this information, it is possible to reconstruct exactly what happened during an incident, and what the operator did about it.

Addressing The Gaps

Pipeline operators are starting to apply video systems as part of their operating practice. Here is how video can fill the various gaps in operation:

- Cluttered data displays: An NTSB study indicated that one pipeline operator experienced 18 alarms in four minutes – a rate of 270 alarms per hour! Others reported rates of 100 per hour – about one every 40 seconds. Even with multi-tiered alarm priorities, there is the possibility of confusing the controller in the control room. The SCADA or HMI display, designed years ago when the system was first installed, has a basic format that was never intended to handle the massive amount of information available today. If a variable enters a pre-alarm condition, will that condition catch the controller’s eye, or will it be hidden in the clutter of information? A video picture can be worth 1,000 data points on a cluttered screen.

- A low pressure alarm comes in from a compressor station. What caused that alarm? A bad sensor? A leaky gasket? A failed motor? Can the operator determine the cause and action to take by looking at a stream of alarm messages and data indications? Or do you need to send a technician in a truck to drive a few hours out to the site to decide what to do? Video can give timely, unambiguous information to support the decision on what action to take.

- Many industries are facing a reduction in operating experience through retirements or reductions in staff. How do we train new controllers and technicians? How do we get them up to optimum performance quickly? Video recordings of actual events and actions, combined with playback of simulator sessions, are proven tools that make training more effective. With the advent of video recording of operation consoles, supervisors now have a simple yet powerful tool to review plant operations. The Longwatch Console Recorder, for example, records all information shown on the console display as video (Figure 1). By tying this video to the alarms and actions in the SCADA system, trainers and managers can go back and review exactly what the operator was seeing at any point in time, even when alarms occurred.

- Field sites can be located in remote locations, or in urban or suburban locations where encroachment occurs (one compressor station was built in a field, but a developer subsequently put a school and subdivision nearby). These locations can become magnets for vandals and trespassers. Chain-link fences provide a small deterrent but, more often than not, the buildings are entered for reasons ranging from theft of valuable items (such as copper) to generating gang notoriety. Video attached to intrusion alarm messages is a fast and effective means to help the operator determine if an alarm is false or true, and whether the intruder is a deer or a person. Work rules might also dictate that any site visit be performed by two people to ensure safety. This takes two people away from other areas, often for hours. With video, the operator can be electronically transported to the field. This saves time and money, and it helps more staff people be available for other tasks.

Transmitting Video

Video data can easily be transmitted over the pipeline’s ground-based network, but that network can fail if a pipeline explosion occurs and cuts the link. Some pipelines rely on wireless technologies to transmit video, security and instrumentation data, using radio, cellular or satellite communications.

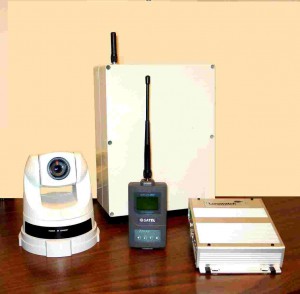

Pipelines that use dedicated radio networks can transmit data packets of varying sizes at various times. Depending on the frequency used (and the power available), the radio distances between the remote and master station (or between the remote and repeater radios) can range from one to 30 or more miles. Newer radio modem technology has provided continually improving speeds while using commonly used frequencies (Figure 2). Ironically, the slower speed frequencies tend to carry longer distances (without line-of-sight issues) while the faster-speed frequencies cover shorter distances (and often require repeaters which add to the door-to-door transmission times.)

Figure 2: The WIPAT remote video monitoring system from Satel-West transmits video clips, still images, event logs, access control data, multiple digital sensor inputs, and output contacts for control of devices via wireless public safety channels or satellite connections. It can operate from solar power.

Satellite communication provides a very convenient means of connecting remote sites back to the control room. Given the constellation of communication satellites available, the task is often just setting up the radio and antenna. Satellites often provide much higher communications speeds than ground-based systems, although their operating costs can be higher. Satellite communication is often done in “burst” mode of small data packets to keep costs down. While small data packets are not much of an issue when transmitting a sensor’s value or status, they can provide an engineering issue if large data stream transmission is necessary.

Cellular “gateways” (using cellular telephone technology) can provide cost-effective, high- performance wireless TCP/IP data communications via cellular networks for connecting remote sites and devices. This communication pathway is secure and “always on,” allowing for on-demand transfer of data to both Ethernet and/or serial devices.

Setting up a cellular gateway is often simpler and much less expensive than installing a point-to-point wireless system. If cost is a consideration, video transmission can be configured so that images from remote sites are sent at lengthy intervals; say, a single image from the camera sent once every five minutes. This gives the operator an updated view of the remote site without utilizing large amounts of bandwidth. If an alarm occurs, video can instantly change from sending these static images to live streaming video transmission (within the limits of the bandwidth supplied by the network).

Putting Video Cameras In The Field

Commercial off-the-shelf (COTS) products can offer a great deal of application flexibility and lower costs, but it is important to select hardware and software that is designed for industrial applications and low-power operation. For example, a video camera located in a compressor station usually has access to line power so that the camera, video recorder and communications interface can be active all the time. These conditions are not always the case for field surveillance.

At a remote well (or other) site, the power may be limited to solar cells and batteries, requiring the video equipment to “hibernate” until something of interest occurs. When that event happens, COTS equipment wakes up, performs its functions (placing only a temporary burden on the power and communications resources) and then goes back to sleep. This is not a good situation for pipeline surveillance, because video cannot be active all the time, and no continuous record can be kept. When selecting a video system for pipeline work, especially in remote areas, look for:

- Low-power IP digital cameras with built-in analytics to detect abnormal conditions (spills, intruders, etc.). Such systems can trigger alarms based on what they see in the video image.

- A system that records and processes video data at the remote site. This eliminates the need for sending data constantly, because all video is recorded and archived locally, and can be transmitted on demand to a central station.

- A system that can operate continuously from solar and battery power.

- Video images need compression to reduce the load on the network, so smart buffering is required so that no video is lost during a network outage (which may occur when the radio system is down, or when the network is busy handling a flurry of control messages during a field or plant event.)

In many remote site applications, video systems are configured to operate continuously, even on battery power. The Longwatch Video System, for example, continually records video at the field site into solid-state memory (Figure 3). When an alarm occurs, the system transmits an alarm message with a video “snippet” attached. This snippet contains video from one or more cameras, from a few seconds before the event occurred to a few seconds after (because it’s recording all the time, Longwatch can access archived video up to several days or weeks before the event).

Figure 3: Network layout for a Longwatch Video Surveillance System. Multiple cameras, PLC, door access switches and other hardware connect to a Longwatch Video Engine. The Video Engine transmits video images and receives instructions via a cellular, wireless, satellite or RF network. At the control room, incoming video packets go through a firewall and router onto the local LAN, then to the Video Control Center, where incoming packets are reassembled into a video stream. Videos can be played on the local HMI, such as a Wonderware or GE Fanuc system.

The result is an alarm message delivered to the SCADA console that shows the operator visual information of what triggered the alarm. The operator can then determine what type of response is necessary, and switch to live video to get a continuous video stream. This is faster and easier than looking through an ever-growing alarm list, trying to analyze alarm messages to help draw conclusions about what happened and what to do next.

Conclusions

Both the NTSB and Pipeline and Hazardous Materials Safety Administration of the Department of Transportation have identified several areas where operational gaps have led to costly events. The PHMSA reported that from 2004-2008, the industry sustained more than $2.3 billion in total loss from numerous incidents, including $1.8 billion in industry property damage and more than $121 million in lost product. Video can help mitigate almost $475 million of these costly losses each year.

Author

Stephen Rubin, President and CEO of Longwatch, has more than 30 years of experience in the industrial software industry. He was founder of Intellution, Inc., a leader in the PC-based automation software market. Intellution was acquired by Emerson Electric Co. where Rubin continued as division president until his retirement in 2001. He has been a board member of several software companies and is also past chair of Boynton Angels, a technology investment group. Rubin is a Fellow of the International Society of Automation, and is a member of the board of trustees at Worcester Polytechnic Institute. He can be contacted at srubin@longwatch.com.

Comments