August 2010 Vol. 237 No. 8

Projects

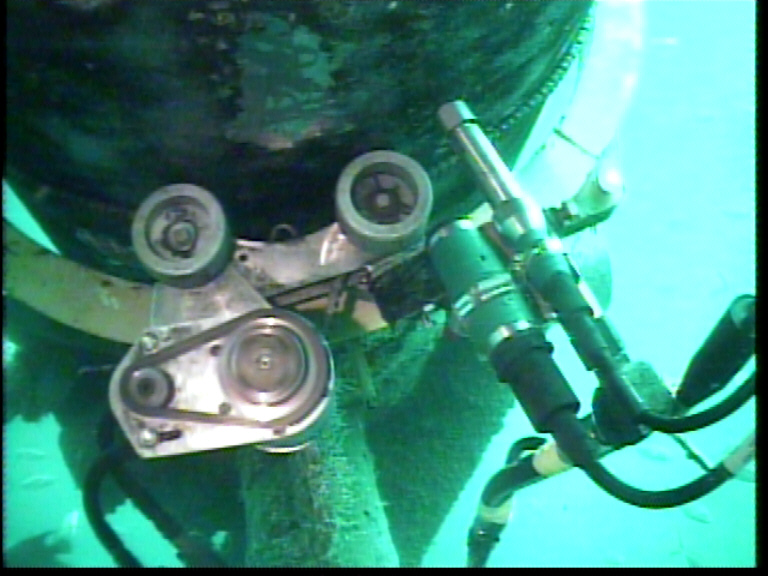

Water Abrasive System Used To Cut Pipe And Concrete In Water As Deep As 1,700 Feet

Dismantling decommissioned oil-drilling platforms, wells and pipelines requires precision demolition techniques. Gulf Coast specialty oil service contractor Proserv Offshore, a unit of Norwegian-based Proserv Group, has become known in the industry for using high-pressure, water-abrasive cutting technologies—also known as cold-cutting—to help remove a variety of oil and gas facilities.

During a single month last year, Proserv Offshore’s Subsea & Marine Technology division, based in Houma, LA, used waterblasting equipment along with abrasive to help dismantle 11 offshore platforms and wells.

Nick Speer, base operations supervisor for the division, said, “We’re a side of the oil industry that doesn’t get much attention but we provide an essential service under difficult and sometimes hazardous conditions. It can be just as satisfying to take something apart properly as it is to put something together.”

The company says the conditions are demanding and the weather often brutal and unpredictable, but the work gets done. Each three-man crew includes a supervisor, a pump system operator and an operations assistant. The company uses customized Jetstream X-series pump units and nozzles for all its hydro-demolition work.

“We have highly trained and experienced crews, but it’s important that they all have capable, efficient and reliable equipment to keep each project on track,” Speer said.

“We designed our own modifications to the standard pump units and worked with Jetstream of Houston LLP on the engineering and manufacturing,” Speer explained. “In a standard configuration, the pump unit is mounted on a wheeled trailer. We designed a skid-mounted version, using all stainless and galvanized steel, and heavier gauge steel for enhanced durability and corrosion-resistance. We also specified that the pressure capacities be machine-stamped on all appropriate components of the system as an additional safety feature.”

Cutting Steel Pipe

Although the waterblasting pumps are rated for up to 40,000 psi, Speer said the company typically operates the units at 10,000-15,000 psi. This provides sufficient power for cutting steel pipe and for removing 2-to-5-inch-thick concrete pipe coatings. Proserv injects abrasive slurry into the water stream beyond the pump for additional cutting power. “There’s not much we can’t cut with it,” Speer said.

He said the company has used the water-abrasive technique successfully in water as deep as 1,700 feet. For underwater applications, the company uses either divers or remote-operated vehicles (ROVs) to deploy the hydro-demolition tools that carry the hose and nozzle.

“The power and accuracy of the waterblasting system is amazing at various depths even beyond 600 feet,” Speer said. “It’s a technology that has become central to our overall capabilities.”

Speer gave the Jetstream waterblasting systems high marks for reliability and serviceability. He said, “Since we switched to Jetstream in 2006, we’ve been happy with their consistent performance and reliability. They require only about one-fifth the amount of maintenance of our previous models, and they’re much easier and quicker to service. We expect to get 10 years of service from these units.”

Comments