August 2010 Vol. 237 No. 8

Features

More Success In Managing Pipeline Projects

When pipeline construction and gas drilling projects are late, the consequences can be much more serious than just cost overruns and contractual penalties. For the operator/owner of the infrastructure, every week that a project runs late is a week of lost revenues and profits. For the contractor, the longer the project takes to complete, the fewer resources are available to pursue new work. Missing deadlines also undermines the contractor’s credibility with customers and lessens the possibility of winning future work.

Despite the significant benefits of accelerating projects and delivering them on time, projects continue to be overdue, over budget, over and over again. This spring, South-African liquids technology specialist Sasol reported that completion of its Escravos gas to liquids (GTL) project in Nigeria may be delayed by a year until 2013, the second such delay, which is now expected to impact Nigeria’s need to import more refined diesel products by tens of thousands of barrels per day. SANTOS’ Queensland liquefied natural gas project is another example. Analysts are expecting this project to be pushed back by at least a year, and some have reduced the company’s stock price target value by 12%.

The question is not why, but how to deliver projects on time. What causes schedule and cost overruns in pipeline and gas projects?

There are many causes for late and failed projects. Contractual agreements, for example, often create a dysfunctional relationship between operators and contractors. If contracts are based on time and materials without adequate incentives for achieving the deadline, there is no reason for the contractor to finish a project early or even on time. In fact, these kinds of terms can serve as disincentives. The longer a project takes, the more the hours that are logged and the more the contractor can charge.

On the other hand, if contracts are set up as a fixed-price agreement, contractors could lose their shirts. What protects the contractor from scope creep eating into their margins? What assurances are there that the client will expedite approvals and testing? If the project is thrown off track by circumstances beyond the contactor’s control, will they have any recourse to adjust pricing?

Another reason for late and failed projects is inadequate assessment and mitigation of risks, but this is an easy problem to fix. All this generally takes is getting experienced people in a room to identify technical, logistical and other risks – and crafting a plan to mitigate them.

Even after overcoming contractual and risk-mitigation challenges, most projects will still take too long. The reason for this is the third and most common cause of late and failed projects: poor synchronization during project execution.

Synchronization Problem

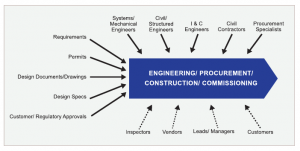

Executing engineering, procurement, construction and commissioning (EPCC) projects is all about synchronization. Various inputs (e.g., approvals, drawings, specifications and materials), resources (e.g., engineers, skilled labor, technicians and inspectors), equipment, decisions and corrective actions have to be brought together in the right place and at the right time throughout the life of a project. However, synchronization is easier explained than achieved.

Figure 1: Infrastructure Project Synchronization.

Desynchronization occurs when uncertainties happen in engineering, procurement, construction and commissioning phases of a project during execution. For example, tasks take longer than expected, vendors and subcontractors miss their deadlines, technical glitches occur, requirements change and expand, engineering designs might have to be redone, local or environmental conditions may cause delays, and issues can come up during integration and testing of systems.

As uncertainties unfold, delays start accumulating and the original schedules that had been so meticulously laid out become obsolete. Faced with both delays and a lack of schedules, individuals and teams involved in execution have to decide on their own what to work on first. These priorities are set locally by team leads or even by the resources themselves, often based on who is screaming the loudest at the time, or which job is easier to finish.

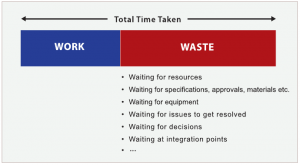

As these local priorities overtake the original plans, soon everyone is marching to a different drumbeat. Work keeps getting interrupted because everyone is waiting for someone else. Sometimes the required inputs – like technical data, drawings and customer approvals – are not available; at other times the inputs are all lined up but the resources – like engineers, technicians, welders, pipefitters, cranes and equipment – are deployed elsewhere. Even when required inputs and resources are available, work is interrupted because the support functions like staging and temporary services are often fighting other fires. Managers get stretched to the limit and delays multiply even further as teams wait for issue resolution and management decisions. Such interruptions account for 50% or more of a project’s timeline.

Figure 2: Timetraps In Project Timeline.

Quality too takes major collateral damage from unsynchronized work. When resources are constantly interrupted and forced to multitask, they lose concentration and workmanship suffers. Quality is also impacted when resources can no longer wait for required inputs and decisions and proceed with their tasks, only to find later that they have made erroneous assumptions and the work needs to be redone.

Though managers attempt to get resynchronized through daily meetings and re-planning, such efforts are often “too little, too late.” Daily meetings can focus only on the superhot priorities and re-planning means that the original due-date of the project can no longer be met.

The traditional response to uncertainties, delays and the resultant lack of priorities and loss of control is two-fold and only makes the situation worse. Here is the two-fold response that makes the situation worse:

1. Starting work on as many fronts as possible makes the situation worse. The rationale is that even if the project gets stuck on one front, resources can be kept busy on others. However, the realty is that the more open tasks, the more difficult it becomes to control what resources are working on. Priorities become more unsynchronized and resources multitask even more.

2. Creating detailed plans and holding people accountable for task-level schedules makes the situation worse. The hope is that if held accountable, people will hold uncertainties down to a minimum. Unfortunately it only causes them to bake safeties into their task estimates – which prolong project plans. In execution, these safeties just get wasted because the underlying problem of unsynchronized priorities has not been solved.

To execute projects faster, managers must have a different response to the inevitable uncertainties when they occur. A key requirement is maintaining synchronization among all the moving pieces, even in the face of uncertainties.

Solving The Synchronization Challenge

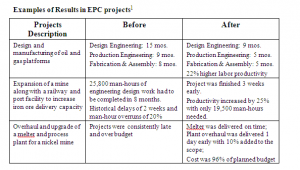

It is against the backdrop mentioned earlier that a new method of managing project execution was invented by Dr. Eli Goldratt. Known as “Critical Chain,” this method has been adopted by a wide range of organizations around the world, allowing them to increase the execution rate of projects by 20-30% (see Table 1).

The Critical Chain breakthrough lies in keeping tasks and resources synchronized within and across projects, even in the face of uncertainties. To synchronize execution, Critical Chain prescribes three precepts, or Rules:

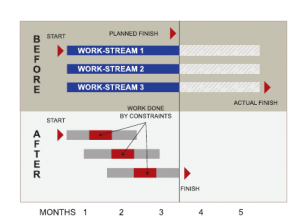

1. PIPELINING: Limit the number of work-streams in execution. When too many work-streams are in execution compared to available capacity – that is, high work-in-progress (WIP) – it automatically spreads resources too thinly and causes priorities to become unsynchronized. Therefore, instead of trying to keep people busy, concentrate resources on fewer streams of work at a time (Figure 3).

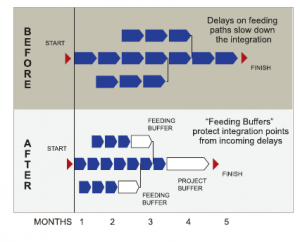

2. BUFFERING: Discard local schedules and measurements, and use aggregate buffers to protect against uncertainties. Instead of finishing tasks on time, focus on finishing the project on time. The final project deadline is the only deadline that really matters (Figure 4).

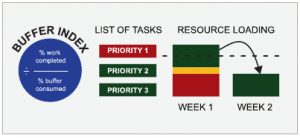

3. BUFFER MANAGEMENT: Instead of creating highly detailed plans, focus on task prioritization – use the rate of project buffer consumption to measure execution, and give highest priority to tasks that are consuming buffer at the fastest rate. Buffer-based priorities not only are synchronized, but they also cause project status to be reliable, giving managers actionable information they can use to focus resources on the tasks that are causing the biggest delays in project completion (Figure 5).

While the precepts themselves are relatively simple, implementing and sustaining them throughout an organization requires effort. Since Critical Chain upends many long-held beliefs about how project execution should be managed, the top executive team must buy into and support the change. Without their leadership, any attempt to synchronize execution will fail.

All participants in the pipeline and gas drilling value chain can capitalize on the benefits of synchronized execution to complete large, complex projects faster with only existing resources, and can improve their competitive advantages in the industry.

Author

Sanjeev Gupta is CEO of Realization Technologies. He can be reached at 408-271-1720 or info@realization.com.

Comments