August 2009 Vol. 236 No. 8

Features

Challenges, Hazards And Benefits Of Pipelines Crossing The South American Andes

Latin America has an abundance of land-based natural gas and oil reserves, with large amounts found in the Amazonian basin and Andean region.

Normally, these resources are transported to the coastal areas by an ever-expanding pipeline system (Figure 1), where pipelines stretching westward or northward cross an especially diverse environment and geography.

The most significant recent additions to these western-reaching pipeline systems are the Oleoducto de Crudos Pesdaos (OCP) in Ecuador and the Camisea Natural Gas and Natural Gas Liquids pipeline system in Peru. The gas pipelines of the Camisea system are being expanded by construction of a compressor station, a gas liquefaction plant along the Peruvian coast and an additional pipeline. Moreover, new pipeline projects are under consideration, such as the Kuntur pipeline connecting the south of Peru with the Camisea gas field and the further expansion of the existing Camisea pipeline system.

There are extensive gas and oil exploration activities under way which will likely result in additional proven reserves and subsequent need for new pipeline projects. These new pipelines will cover portions of the Amazonian rainforest, the mountain rainforest along the eastern flank of the Andes, the Andean plateau and the rural and urban low lying desert areas of the Pacific Coast.

This article briefly discusses some of the important engineering-related challenges and issues related to pipeline projects in the region. Clearly, there are other important factors (e.g., financial, security, environmental and social aspects) that need to be properly managed.

Government

A clear government expression of interest for a particular pipeline project is needed when the project is not a government concession. For example, an official energy and economic development policy should establish the government’s commitment, and such commitment must be sustained, especially during unanticipated events. Therefore, a clear understanding of the country’s future internal demand for gas and oil versus exportation demands needs to be established. This is especially relevant given the relatively large amount of ongoing exploration and potential development of various pipeline options in Peru.

Government institutional capacity also needs to be considered. Governmental concessions must be properly designed and strong governmental technical supervision and oversight provided. Strong institutional capacity is more critical when dealing with complex pipeline designs requiring governmental review and approval. As more oil and gas activities start, the existing institutional capacity may be stressed, especially if governments attempt to pursue multiple large or “mega-type” projects simultaneously.

There is a strong need for coordinated governmental participation when dealing with multi-sectoral agencies having different responsibilities related to a project. This requires appropriate inter-institutional and sectoral coordination at both a technical and high political level. Special efforts may be needed to help governments meet these demands. While these demands can effectively be addressed in the short-term through external funding, they require proper recurrent governmental budgetary allocation for sustainability. Assistance from international financial institutions, industry associations, and non-government organizations (NGOs) may be an alternative. Companies also need to help where possible, in particular, with technology transfer and training.

Bids And Contracts

Within the request for bids and associated contracts, especially in governmental concessions, the required project risk mitigation measures must be clearly specified with sufficient detail and understanding of the site specific hazards and challenges. Special mechanisms are needed to allow for adequate resolution of unplanned risks and/or unanticipated risks related to the long-term interests of the project, government, local communities, and companies involved. These mechanisms should enable all parties to effectively identify risks and implement fair and cost-effective resolutions.

Often, there is a lack of flexibility in contracts, schedules, etc. to make adjustments during construction to address new or increased risks. Governments and project owners/concessionaires must provide clear incentives to contractors to promote superior performance, especially in terms of risk mitigation. Concession and project contracts need to allow for sufficient design and construction time to mitigate project risks. This does not necessarily mean more time in the field at individual locations, where social and environmental impacts can occur. Contractual time schedules must also consider key factors such as logistics (e.g., pipeline transport to project site), weather (e.g., ability to construct during the rainy season), productivity given the construction workforce, potential harsh physical/environmental conditions along the pipeline right-of-way (ROW), security concerns, and community social issues along the ROW.

Design

Pipelines in this region commonly use the applicable pipeline engineering codes of the American Society of Mechanical Engineers (ASME) and the Code of Federal Regulations (CFR) of the U.S. However, these pipeline projects are located in areas with limited or no field data, which complicates sound engineering- and risk-related decisions. For example, adequate baseline geological mapping and geologic/geotechnical risk identification is needed for terrains with dynamic geotechnical hazards. When designing for potential scour at river crossings, rarely will historic flow data be available for consideration. Frequently, more data collection will be required either by governments prior to concession award or by the concessionaire subsequent to award, and the required time must be included in concession or project design.

Development of comprehensive and risk based maintenance plans should be considered early on in the design phase of the project, including the identification of characteristics and resources to monitor conditions. Designs also need to properly evaluate the tradeoffs between risk mitigation measures, such as using cut-fill measures to limit environmental impacts during construction, which may in the mid to long-term result in increased geotechnical risk during pipeline operations.

From a geographic perspective, the mountain rainforest at the eastern flank of the Andes with peaks of 3,000 meters, a vast network of large rivers and streams, annual rainfall in excess of 5,000 mm, steep slopes, and soils with low-bearing capacity provide many engineering challenges that need careful consideration by the designer. Hydrostatic pressures of liquid pipelines can vary over short distances by 100 bar from mountain peak to valley. Selecting an alignment along narrow valleys with smaller hydrostatic pressure fluctuation is typically impractical in this region. A midslope pipeline alignment along the side slopes exposes the pipeline to a significant landslide risk. Therefore, pipelines in this region are commonly aligned along or near mountain ridges.

In order to avoid geotechnical hazards like creep, rockslides, mudflows and landslides geologic mapping hundreds of meters beyond the ROW is of utmost importance. In cases where geotechnical hazards cannot be avoided, engineers need to develop site-specific solutions to minimize the risk to pipe integrity, specifically the risk of excessive external soil forces being applied to the pipe. This may require the design of significant geotechnical stabilization, improved drainage and water management works, as well as the selective specification of pipe material and girth welds that accommodate large ground deformations.

Crossings of large rivers in the Amazonian basin and their fast-flowing tributaries with rapidly increasing flows (flash floods) and scour potential are another engineering challenge of this sector. Very little accurate flow data is typically available and flash floods are common due to heavy torrential rainfall and landslides that temporarily block these rivers. The sensitive nature of this environment suggests that river crossings should be designed with a flow rate return period in excess of 200 years and conservative factors of safety consistent with the reliability of the underlying data.

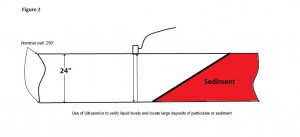

Typically, the coastal segments of these pipeline systems descend steeply from high altitudes toward the Pacific Ocean. Commonly, pressure-reduction stations and reduced pipe diameters are used to keep the operating pressure below the maximum allowable operating pressure. However, main hazards along the coastal segments are higher population densities, causing an increase in third-party damages, and seismicity. Peru and northern Chile are located along a segment of the circum-Pacific seismic belt where the continental block of South America is drifting westward, overriding and forcing down the denser Pacific Ocean (Nazca) crustal slab (Figure 2).

Approximately two-thirds of the earth’s largest magnitude earthquakes occur in this seismic belt. For example, during the past 60 years, 13 earthquakes with moment magnitude Mw ? 6.7 have been recorded in or off the coast of Peru. Seismic design consideration needs to be taken into account for the coastal and western part of the Andes, ranging from indirect effects like permanent ground deformation and the direct effects of wave propagation. These loads can lead to tensile failures or local buckling of the pipe wall due to excessive compressive stresses, wherein failure initiates in the form of a circumferential wrinkle, with subsequent circumferential as well as axial cracking at the wrinkle.

The Andean high-altitude plateau faces a mixture of the above-described hazards with seismicity being less intense at the eastern portion. Nevertheless, permanent ground deformation is still a concern in this area because slope stability is typically low. River crossings are especially vulnerable in this area because of debris and mud flows which can mobilize large boulders and can carve out completely new river beds in a matter of days.

Construction

Pre-construction planning related to main project construction risks is critical, in particular for erosion control associated with pipeline construction, works in sensitive environmental areas, areas with social unrest, or areas in or near indigenous reserves or populations. Major training efforts are needed for the construction workforce, especially on quality control and worker health and safety, in a manner applicable to educational and cultural characteristics. Special road-safety measures are required for transporting materials and workers in remote or rural areas. In many instances the ROW will be the only means of transporting construction material. There will also likely be the need for extensive use of helicopters. Transportation on existing roads requires training for drivers, physical improvements and ongoing maintenance of the roads, and implementing special construction worker road transport mechanisms.

Other special logistical challenges are presented by the rich cultural history of the Andes. There are many undiscovered archeological treasures. This cultural heritage will need to be preserved; potentially necessitating a change of the pipeline alignment. It is instances like this of anticipatable but uncontrollable events where good communication and pre-construction socio-economic development will facilitate mutually beneficial project advancement.

Therefore, all the above actions must be done in coordination with applicable governmental entities and the representatives of the local community. Sponsors/owners also need to provide expanded construction contractor oversight given the complexity of actions and the significance of poor performance. This implies full-time qualified experts in the field to help identify and take actions to mitigate potential risks.

Operation

Many of the logistical challenges one faces during construction still exist during operation. Typically, the pipeline can only be accessed by foot or helicopter, especially in the rainforest. Therefore, well-thought-out monitoring programs with real time data feedback are of special value in this sector. It is preferable if these systems are integrated into a geographic information system (GIS)-based pipeline integrity management (PIM) program. This program should be consistent with the requirements outlined in the CFR and API 1160.

Special consideration needs to be given to external natural hazards like landslides, soil creep, seismicity and river scour. The development of quantitative risk assessment methods of geotechnical failure modes is needed and requires site-specific data to be collected. The PIM program needs to be developed early on, include effective corrosion programs, and the early deployment of inline-inspection (ILI) tools. In this regard, the pipeline operator needs an accurate pipe survey from the contractor in order to compare and calibrate the inertia based ILI data, which allows subsequently identification of ground movement.

The operator must also take into account that pipelines with large changes in elevation typically operate at low pressures at high altitudes and therefore hydrostatic test pressures may be rather low and not sufficiently large to force the fracture of preexisting defects. These defects can grow over time and are of special concern where external loads are imposed on the pipe. Also, magnetic flux leakage (MFL) ILI tools have been shown to detect ever-smaller defects; however, they are not capable of detecting circumferential cracks, except when external loading conditions are already critical or environmental degradation has increased the crack mouth opening.

As a last line of defense, state-of-the-art leak-detection systems with strategically placed block valves at reasonable intervals ought to be installed to minimize spillage volume. This is especially true in areas where rivers can transport liquid hydrocarbons downstream.

Management

Due to the complexity of these pipeline projects, project owners, constructors and operators must use their best personnel. Senior management must provide the necessary commitment, support and resources – beyond normal practice – in the areas of engineering as well as environmental, social and communication.

These projects invariably have significant engineering challenges that arise during construction and operation regardless of the breadth, adequacy and implementation of design mitigation measures. Given this reality, sound management requires a willingness and ability to adequately identify, understand and accept issues when they exist, and to take the necessary actions to properly address and resolve the identified issues. Additionally, the project contracts need to account for such potential issues. For example, the use of fixed-price-plus Engineering, Procurement, and Construction (EPC) contracts are needed to allow the appropriate modifications during construction to reduce pipeline integrity risk.

Conclusion

Oil and gas pipelines emanating from the Amazon and crossing the Andes are needed and offer a tremendous opportunity to promote sustainable economic development. However, there are ample challenges in safeguarding the integrity of the pipeline, environment, local population and socio-economic fabric of the region. Failure to properly address these risks could have significant financial, environmental and reputational consequences for operators, contractors, financiers and governments. In this context, companies need to appreciate the specific challenges present and implement an encompassing risk-management strategy that proactively responds to evolving conditions.

Alfred M. Pettinger, Ph.D., P.E., is a senior managing engineer in Exponent’s Mechanical Engineering and Materials/Metallurgy practice. His areas of expertise include mechanical behavior of materials, structural engineering, product design, reliability, durability, and maintainability. He can be reached at 949-341-6000, 949-242-6004, apettinger@exponent.com, www.exponent.com.

Robert H. Montgomery, Ph.D., is a senior manager in Exponent’s Environmental Sciences practice. The focus of his 25 years of successful international experience has been helping private-sector companies and financial institutions manage environmental, social, health and safety, and labor aspects of their businesses. 202-772-4935, rmontgomery@exponent.com.

Comments