July 2020, Vol. 247, No. 7

Metering and Measurement

Aligning Operating Procedures with Land Management Orders

By Russel Treat, President, Gas Certification Institute (GCI)

In 2016, the Bureau of Land Management (BLM) published revisions to the Oil and Gas Measurement Regulations (43 CFR 3170s) for conducting oil and gas operations on federal and native American lands. This 2016 rule, made effective in January 2017, updated the BLM Onshore Orders to incorporate the latest industry standards and to meet the following objectives:

- Ensure oil and gas operating locations are properly and securely handled to prevent theft and loss.

- Enable accurate measurement and production accountability.

- Ensure companies meet minimum standards for the accurate measurement of oil.

- Ensure companies meet minimum standards for the accurate measurement of gas.

The 2016 rule sets out standardized practices to create consistency in how measurement is performed across a wide range of geography and operators.

Onshore Orders

- 43 CFR 3170 – Onshore oil and gas production contains a general overview of the regulations for onshore oil and gas production, including general requirements and definitions.

- Subpart 3173 – Site security and production handling establishes standards for properly handling product, preventing loss and creating accountability for who is responsible for the accurate measurement of the product on federal and native American lands, including site security, commingling and off-lease measurement.

The rule highlights the importance of establishing facility measurement points (FMP) where measurement takes place at each point in the oil and gas value chain as production moves from the ground to the market. An FMP is the BLM-approved point where oil or gas produced from a federal or Indian lease is measured, and where that measurement affects the calculation of royalty owed. All BLM recordkeeping is associated with FMP numbers.

Midstream companies need to determine if they are acting as the “recordkeeper” for the BLM royalty point. Coordination between “partners” (midstreams and operators) is important since the production operator is responsible for obtaining the FMP, even though the midstream may be the recordkeeper.

Midstream companies should examine their contracts, as they may indicate their responsibility for measurement and recordkeeping:

- Subpart 3174 – measurement of oil establishes the minimum measurement standards for measurement of produced oil on BLM-managed lands.

- Subpart 3175 – measurement of gas establishes the minimum measurement standards for measurement of natural gas produced on BLM-managed lands.

While producers may not be the royalty point in the value chain, they will ultimately be accountable for meeting the requirements of both 3174 and 3175.

Overall, 3173, 3174 and 3175 have a direct effect on measurement standard operating procedures (SOPs) for both producers and midstream companies operating on BLM-managed lands.

Because the 2016 rule has been effective since January 2017, many oil and gas companies have already updated their measurement SOPs to ensure their measurement practice on BLM royalty properties conforms to the 2016 rule.

Facility Measurement Points

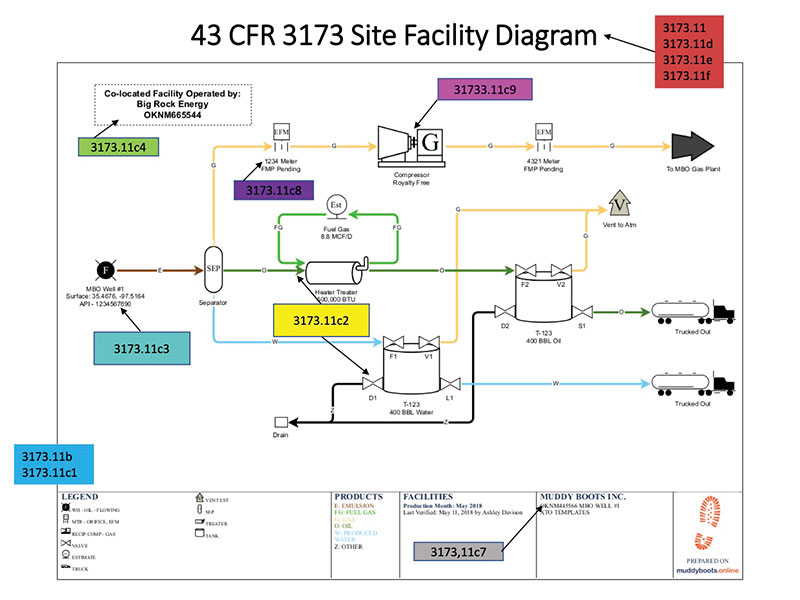

CFR 3173 provides specific guidance on FMPs (facility measurement points), site security, production handling and commingling. This aspect of the rulemaking highlights the importance of incorporating site facility diagrams into measurement SOPs.

Operating companies with BLM FMPs must have site facility drawings for all locations where oil or gas is produced on federal or Indian lands. If your company’s measurement schematics are out-of-date or do not exist, you will be required to update or create these diagrams to satisfy Subsection 3173.11.

Consider this example diagram as a starting point to develop the schematics that will add value to your measurement management processes.

Subpart 3170 requires that BLM royalty operators have 3173-compliant site drawings available when a BLM authorized officer (AO) arrives onsite to review activity.

Once a BLM FMP comes online, the operating company has 30 days to submit the FMP so all future recordkeeping will reflect the FMP number regardless of measurement type [i.e., tank, LACT, electric gas measurement (EGM) or other measurement device].

Updating Measurement

This 2016 rule strengthens the BLM policies governing production accountability for oil produced on BLM-managed lands. The critical elements that affect measurement SOPs or should be reflected in SOPs for oil measurement include the following:

Companies need to obtain and incorporate FMP numbers for all measurement sites (according to the 3173 facility map diagram).

Operators are required to meet the BLM schedule of master proving. Instead of requiring meter proving quarterly, or every 50,000 barrels, the final rule will require meter proving to be at least quarterly, or every 75,000 barrels, whichever comes first, but no more frequently than monthly.

All FMPs must meet uncertainty requirements. The BLM established two tiers to determine uncertainty limits:

FMPs measuring an average monthly volume equal to or greater than 30,000 bbl per month will be subject to an uncertainty limit of ±0.50%. FMPs measuring an average monthly volume less than 30,000 bbl per month will be subject to an uncertainty limit of ±1.50%.

Equipment installed after the 2016 rule effective date (January 2017) must comply with an approved PMT (production measurement team) list. The PMT evaluates measurement equipment for oil and gas measurement. At present, the PMT is developing this list.

For system commissioning, approved systems should include only LACT (lease automatic custody transfer) measurement stations consisting of positive displacement (PD) meters or CMS (Coriolis) according to the API 21.2 industry standard. Access and data security measures should be implemented that, at a minimum, secure the measurement data collected and transmitted.

Meter proving should be conducted on all LACT startups with the BLM AO in attendance. Tank gauging should be performed in accordance with API 3.1A and API 18.2. Tank gauging should be submitted within 30 days of new installation, re-strap or repair.

Companies should operate and report within BLM calibration requirements.

Gas Measurement

This 2016 rule is focused on (a) minimum requirements for installation and meter tube inspection frequency, (b) EGM commissioning, verification and calibration in alignment with API 21.1 and (c) minimum requirements for gas sampling and related reporting to BLM.

SOPs should be updated for meter tube installation. Also, meter tube inspection must meet the minimum requirements of Subsection 3175.80. When updating SOPs for meter tube installation and inspection, keep in mind these elements to include:

- Identify the schedule for both a basic inspection and a detailed inspection.

- Identify the borescope or equivalent for meter tube internal inspection.

- Create a checklist to ensure proper records if the BLM does not attend the inspection but may request the records later reflecting your procedure(s).

- Notify the BLM before each installation startup and inspection.

SOPs for electronic gas measurement (EGM) must comply with Subsection 3175.30 that incorporates by reference API 21.1 for EGM system commissioning. When updating SOPs to ensure EGM compliance, keep in mind these elements:

- Identify EGM commissioning procedure according to API 21.1 and determine that the implementation conforms to Subpart 3175, the verification and calibration procedure (reflecting the BLM schedule).

- Create a record or checklist for the commissioning process, verification and calibration process for BLM records and ensure the capability to provide a BLM AO the last 10 EGM configurations and the last 50 alarms and events.

SOPs must cite policies including verification after installation or following repair, while showing when the company has made volume corrections and showing test equipment certification schedules.

Measurement SOPs should also reflect gas sampling and analysis to satisfy Subsection 3175.110.

Gas sampling has the highest focus of all processes in Subpart 3175. Additionally, the requirements for capturing, analyzing and reporting a sample is highly detailed with the highest visibility for the BLM AO.

When updating SOPs to ensure gas quality compliance, keep in mind the process of taking gas quality (e.g., spot sampling or chromatography) and reflect spot sample uncertainty and frequency in alignment with Subsection 3175.31.

For high and very high volumes, the SOPs should identify reporting that demonstrates that sampling meets the uncertainty requirement based on 3175.31.

SOP updates should capture all BLM gas measurement fields for BLM reporting.

The correct sample probe installation and procedures should be detailed in accordance with API 14.1, Subsection 6.4.2 and ensure the maximum time between samples conforms to 3175.110.

The update should detail installation of insulation and heat tracing to ensure the ambient temperature for samples meets minimum requirements, while reporting gas analysis reporting and verification system (GARV) data for each FMP to the BLM system that will be online in the future.

SOPs need to reflect that all online gas chromatographs (GCs) are installed, operated and maintained under the requirements of GPA 2166-05 and show that each of these has been installed, operated and calibrated according to GPA 2261-13.

Underlying this process of updating measurement SOPs to align with the new rulemaking is the importance of recordkeeping. The BLM Records Retention Policy includes various requirements for oil and gas companies to maintain records for oil and gas production on federal and Indian land.

When updating measurement SOPs to align with the BLM Onshore Orders, make sure that your company also updates recordkeeping processes to maintain accurate and reliable records to satisfy a BLM review.

If you have not already taken steps to review and update measurement SOPs to meet 34 CFR 3170, Subparts 3173, 3174 and 3175, it is time to start.

Doing the leg work now will best position your company or operation to satisfy a forthcoming BLM review to support operational integrity.

Future Changes

In 2017, Executive Order 13783 on “Promoting Energy Independence and Economic Growth” and Department of the Interior Secretarial Order 3349 on “American Energy Independence” precipitated a discussion on BLM Oil & Gas Measurement Regulations, and identified the following areas of possible change:

- Address implementation challenges identified following the 2016 rule becoming effective.

- Reduce operating and administrative burdens.

- Update or modify references to industry standards.

- Standardize section numbering across the subparts.

Currently, the BLM is developing a proposed rule that addresses the goals stated above, while continuing to ensure the government’s ability to ensure accurate and reliable royalty collection. The elements being considered were presented at the API Fall Meeting in October 2019.

As with any federal rulemaking process, there is no guarantee regarding the content, effective date or even eventual implementation of any rule. However, for oil and gas companies operating on federal lands, the challenge is to ensure that their measurement SOPs conform to the BLM Onshore Order requirements if and when they are actually revised.

Russel Treat is the president of Gas Certification Institute (GCI), which provides measurement SOPs for pipeline operators and midstream, production and exploration companies. He is also the host of the Pipeliners Podcast (www.pipelinerspodcast.com), where he regularly discusses measurement topics with industry experts.

Comments