July 2020, Vol. 247, No. 7

Features

Pilot Plant Advances Supercritical CO2 Power Cycles for Gas-Fired Generation

By Timothy C. Allison, Ph.D., Southwest Research Institute (SwRI), San Antonio, TX

Power cycles utilizing supercritical carbon dioxide (sCO2) as a working fluid show promise for many power generation applications, including high-efficiency waste heat recovery on pipeline gas turbines.

Component development efforts for commercializing these power cycles have progressed rapidly in recent years, and the technology is poised for demonstration at the 10-MWe scale at the Supercritical Transformational Electric Power (STEP) pilot plant that is nearing completion. These power cycles show promise to improve the cost, efficiency and responsiveness of power generation.

sCO2 power cycle technologies utilize CO2 at pressures and temperatures above the critical point [1,070 psi (74 bar), 88°F (31°C)] as a working fluid in a closed cycle system, with some similarities to steam Rankine cycles.

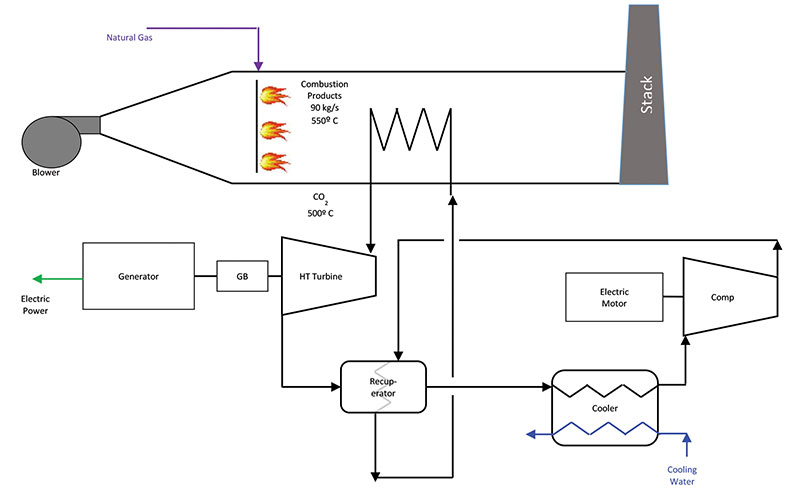

A simple recuperated Brayton cycle uses sCO2 (Figure 1), where sCO2 turbine exhaust heat is transferred to the heater inlet to increase cycle efficiency. More complex cycle architectures include additional complexity to achieve higher efficiencies,1 resulting in more heat exchangers or turbomachinery components.

Most sCO2 cycle applications can provide heat input to the cycle through a heat exchanger from gas turbine exhaust, solar thermal, geothermal or even nuclear sources. Some direct-fired variation such as the Allam cycle2 are directly heated through high-pressure oxy-combustion of natural gas.

sCO2 systems offer high fluid density at low temperatures, enabling relatively low compressor work and extremely power-dense turbomachinery and heat exchangers. The thermodynamic properties of sCO2 offer better efficiency than organic Rankine cycles at low temperatures and improved efficiency vs. steam Rankine cycles at turbine inlet temperatures exceeding 1,000-1,100°F.

The high-power density of sCO2 is attractive for waste heat recovery (WHR) applications due to the potential for compact system packaging and fast startup capability, all with an inert fluid. Although sCO2 cycles have been conceptualized since the 1960s, recent advancements in heat exchangers and turbomachinery components have enabled their implementation into hardware.

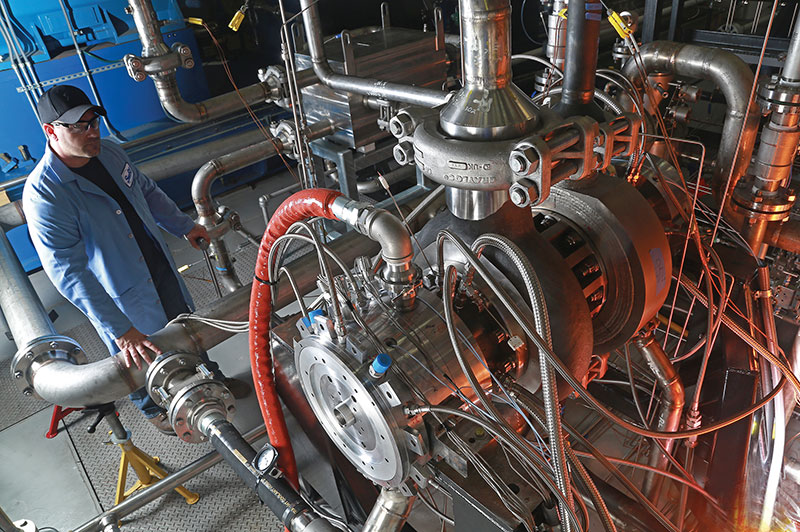

In recent years, sCO2 research programs have targeted multiple technology gaps including the development, construction and operation of multiple MW-scale test loops1-4 and prototype development and validation of multiple compressor and turbine designs.3,4

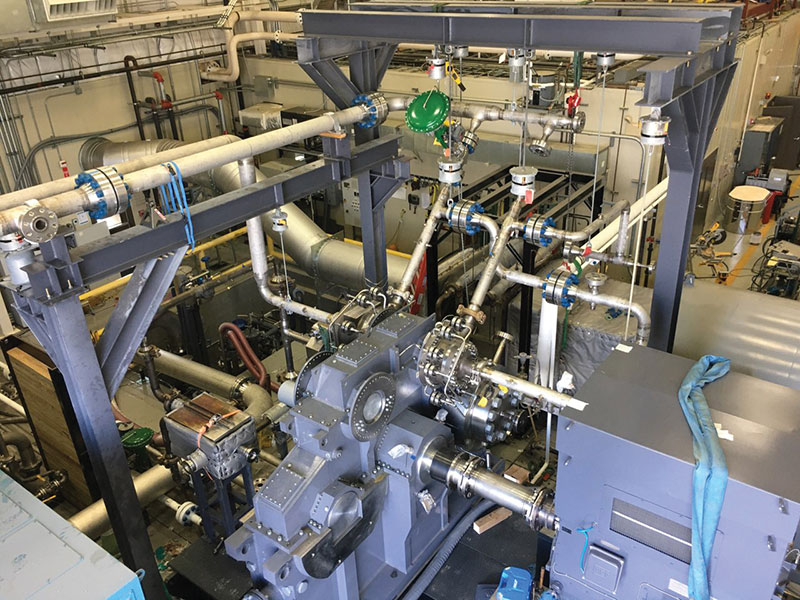

Notable recent successes include the successful full-pressure full-temperature operation of a 10-MWe axial expander prototype up to 1,320°F (716°C) and 3,600 psi (248 bar)3 and ongoing tests for an integrally geared compressor-expander prototype4 (Figure 2).

Research projects targeted specifically at gas turbine WHR systems are underway, adapting high-temperature machinery designs to lower-temperature WHR operation and developing mature technoeconomic models for design optimization over a range of ambient temperatures and typical load profiles.5

Combined cycle analysis results show that plant efficiencies near 50% are achievable even for small-scale, ~20-MW systems with no changes to the gas turbine and with high part-load efficiencies well above open-cycle gas turbine values.

Pilot Plant Advances

The team of Southwest Research Institute (SwRI), Gas Technology Institute and General Electric (GE) are advancing sCO2 technology by designing, constructing and operating a pilot plant test facility to demonstrate sCO2 power cycle technologies at a commercially relevant scale.6

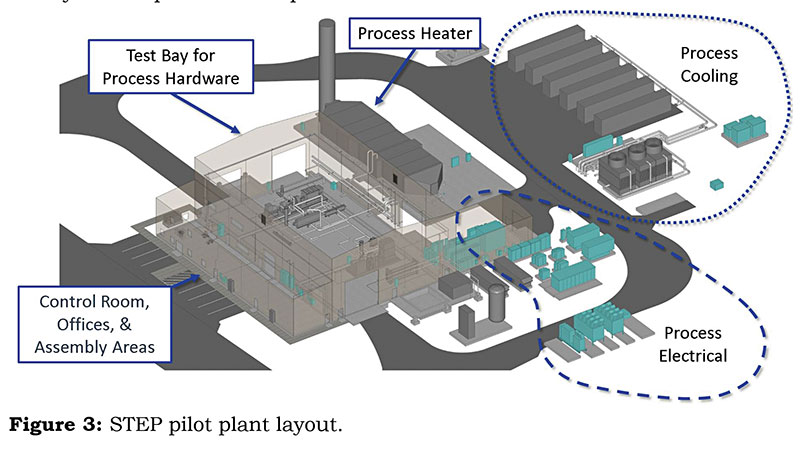

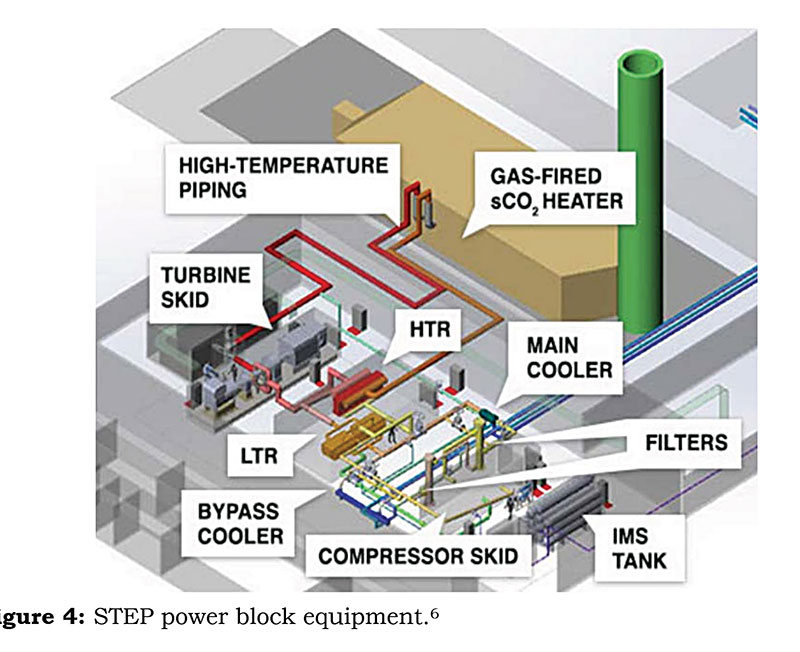

STEP is a state-of-the-art facility located at SwRI in San Antonio, Texas, and is valued at $124M with primary funding provided by DOE and with cost-sharing from industry partners and the State of Texas. The overall facility layout and sCO2 power block components is shown in Figures 3 and 4, respectively. This pilot plant will advance these technologies to near-commercial readiness, demonstrate their operability and performance and serve as a reconfigurable test facility for component development and validation.

Designed at the 10-MWe scale and for operation at sCO2 turbine inlet temperatures up to 1,320° F, the STEP pilot plant is a significant scale-up from existing sCO2 test loops and designed as a fully integrated and functional electric power plant. This project mitigates technical risks and challenges for key components, including the turbomachinery, recuperators and materials. The facility will demonstrate the aerodynamics, sealing performance and durability of full-sized turbomachinery for sCO2 power cycles scalable up to 100s of MW.

The performance, fabrication and durability of compact heat exchanger designs will also be proven. The project sources materials for large-scale hardware and will verify the corrosion, creep and fatigue characteristics of these materials in high-temperature CO2. Finally, the project will demonstrate successful integration and operability of all system components through many operating states, including startups, transients, shutdowns and different ambient conditions.

The current project has achieved definition, specification and procurement activities for numerous major critical components, including:

- Primary process heater provided by Optimus Industries, LLC incorporating a ~80-MWth gas-fired burner and heat recovery steam generator (HRSG)-style CO2 heater fabricated from Inconel 740H for operation up to 1,320° F

- 16-MW (gross) axial turbine jointly developed by SwRI and GE with 100,000-hour design life at inlet conditions of 1,320 °F and 3,626 psi (250 bar); long-lead rotor and casing procurements place and fabrication in process

- High-temperature and low-temperature recuperators fabricated by Heatric; designed as compact printed circuit heat exchangers (PCHEs)

- ~4-MW API 617 real gas compressors provided by Baker Hughes

- Turbine control/stop valve developed by GE and based on their existing commercial product line of steam valves, but with modifications leveraging advanced ultra-supercritical (AUSC) steam power development efforts and with changes to accommodate sCO2 fluid and high operating temperatures

- High-temperature piping designed to ASME B31.1 and fabricated from Inconel 740H

- Balance of plant equipment including low-temperature piping, 25-MWth cooling towers, coolers, valves and CO2 supply and inventory control systems; 16-MW load banks

- Construction of a 22,000-square-foot facility on a 5-acre SwRI campus in San Antonio, Texas, is complete (Figure 5) with certificate of occupancy received in May 2020. The facility includes a 13.2-kV electrical system and 30-ton liquid CO2 storage.

The primary process equipment will continue to arrive on-site for installation and assembly throughout 2020 and into the beginning of 2021. Commissioning and operation of the facility is expected before the end of 2021. Initial testing is planned for a simple cycle architecture (Figure 2), with a second round of testing for a higher-temperature recompression Brayton cycle configuration afterward.

After this program is complete, the reconfigurable facility is anticipated for future use to perform validation testing of alternate component designs, cycle layouts, or control logic. The system may also be extended to include additional components (e.g., thermal energy storage, oxy-combustion hardware) or to perform validation/qualification testing of full-scale waste heat recovery systems.

References :

- Brun, K., Friedman, P., and Dennis, R. (2017), Fundamentals and Applications of Supercritical Carbon Dioxide (sCO2) Based Power Cycles, Woodhead Publishing.

- Allam, R.J., Fetvedt, J.E., Forrest, B.A., Freed, D.A., “The Oxy-Fuel, Supercritical CO2 Allam Cycle: New Cycle Developments to Produce Even Lower-Cost Electricity from Fossil Fuels Without Atmospheric Emissions,” ASME Turbo Expo Paper GT2014-26952, Dusseldorf, Germany.

- Moore, J.J. (2019). “Development of a High Efficiency Hot Gas Turbo-Expander and Low Cost Heat Exchangers for Optimized CSP sCO2 Operation,” Solar Energy Technologies Office Concentrating Solar Power Program Summit, U.S. Department of Energy, Denver, Colo.

- Wilkes, J., Allison, T., Wygant, K., and Pelton, R. (2019). “Development of an Ultra-High Efficiency Wide-Range Integrally-Geared Supercritical CO2 Compressor-Expander,” Solar Energy Technologies Office Concentrating Solar Power Program Summit, U.S. Department of Energy, Denver, Colo.

- Hoopes, K. Musgrove, G., Allison, T., Pelton, R., and Wygant, K. (2018). “An Advanced sCO2 Waste Heat Recovery System with Applications to Existing Gas Turbine Installations,” Gas Machinery Conference, Kansas City, Mo.

- Marion, J., Kutin, M., McClung, A., Mortzheim, J., and Ames, R. (2019). “The STEP 10 MWe sCO2 Pilot Plant Demonstration,” ASME Turbo Expo Paper GT2019-91917, Phoenix, Ariz.

Comments