March 2018, Vol. 245, No. 3

Features

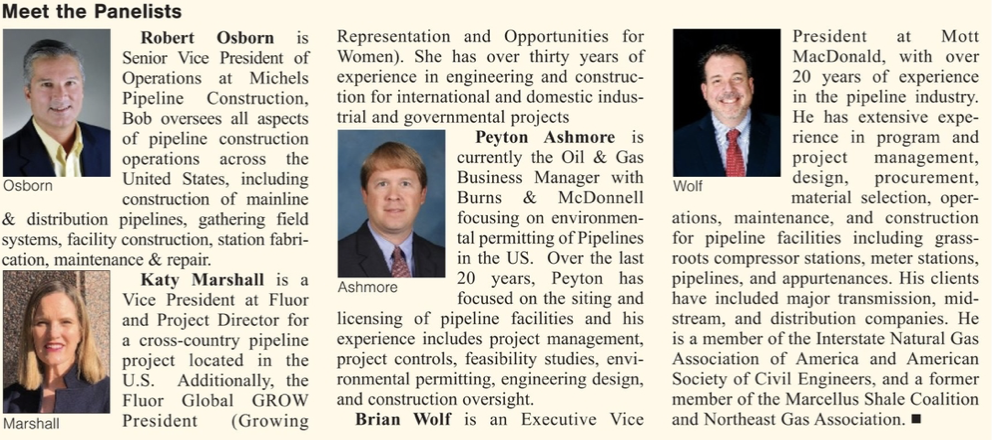

Pipeline Construction Best Practices – Roundtable

P&GJ: What are some of the more challenging aspects to constructing a new pipeline?

Wolf: Getting all the required and necessary permits while managing public perception. Public opposition to pipelines seems to be growing more and more, so it’s important not only to make the regulators see the value of a pipeline but to get the public to see the benefits as well. Up-front planning is critical.

Marshall: With the number of planned and ongoing pipeline projects in the United States, one challenge is the demand for experienced pipeline construction workers. There is an industry-wide shortage for workers, such as welders and inspection staff.

The industry is developing stronger certifications for inspectors which will support the quality of projects industry-wide. Two other challenges are ensuring that all regulatory compliance obligations are met, as well as material delivery. Once construction kicks off, maintaining an accurate schedule of delivery dates and times is critical to project progress. Fluor has an electronic material management system that provides real-time reporting on the status of materials.

Ashmore: We find that working with state and local officials who are not familiar with pipeline construction, the limits of their jurisdictions, and who tend to require information to the point that it can jeopardize the project schedule. Also, the development of design crossing with ROW/easement constraints, the interaction with landowners and non-governmental agencies (NGO’s)

Osborn: Routes are often required to share existing right-of-ways (ROWs). This often limits the new construction temporary work space widths, and pushes the new construction temporary work spaces (TWS) to less desirable topography. The previous infrastructure corridor obviously takes the best terrain, therefore the last one through gets the less preferable locations. Often, we get constricted at the areas/terrain where we need more ROW’s or additional TWS. We also need route developers that are knowledgeable in the requirements and restrictions of large diameter pipe. Constructing large diameter pipelines on steep slopes present much greater challenges than smaller diameter pipelines.

P&GJ: How important is the role of the land-man when it comes to acquiring right-of way?

Osborn: The landman’s role is pretty well-defined as the starting and finishing point of obtaining ROW’s. They start the initial process of obtaining all the necessary information pertaining to the parcel. Once secured, the next step is to have a map or plat of the parcel depicting the boundaries of the individual parcel. Moving on, the next step is to contact said landowner to open up discussions regarding an agreement between the gas company and the landowner for a ROW agreement to run a section of pipe through the landowner parcel to continue the pipe line from point A to point B. During the process of negotiating the agreement, he/she will then have the survey folks come and stake the route that they are discussing. Upon completion of the agreement, and agreed-upon survey, the final documents will be signed and the survey will be turned over to the construction phase of the pipeline. As construction progresses, the landman will act as a liaison between the landowner and the gas company and/or construction company through the entire process of the pipeline construction.

Wolf: Right-of-way agents have a critical role. Because they are often the first people to meet face to face with landowners, agents must understand the company they represent, and understand the benefits of the project for the owner and for the public. An agent needs to develop a relationship and trust with landowners and is responsible for gaining access to the property, securing easements, negotiating compensation, and managing any damages or claims.

Ashmore: The landman is very important as the primary representation of the company to the landowners and building the relationships and trust. They are the perception of the project and can make or break the project based on tactics taken. They are communicating the company’s values and the implementation of any agreements the company makes with the landowners and educating the landowners on construction practices, environmental issues, and high level regulatory issues.

P&GJ: Talk about working with municipalities during a project, positives and negatives.

Ashmore: It is important to work closely with municipalities on projects. They are the local jurisdiction and have the ability to provide insight on issues to avoid and local codes that may need to be addressed. When the local municipalities are properly educated on the project, they can be an advocate for the company and help with potential security issues during construction.

Marshall: Pipeline construction projects provide numerous benefits to local communities and municipalities, including tax revenues, jobs and use of local goods and services. We work closely with clients to address municipalities’ concerns about safety and potential disruptions and maximize the positive impact to the community. We strive to have a sustainable impact in all communities where we live and work, including hiring and developing the local workforce, using local businesses and participating in community development projects.

Wolf: Meeting with municipalities early in the process and understanding their needs is key. It’s also essential to have regular communication and collaboration with them throughout the process, so you know if their needs change. It’s a matter of getting in early, understanding their concerns, and addressing them.

P&GJ: During construction, what are some of the things that keep you up at night?

Wolf: Safety comes first. During construction you must make sure that people act in a responsible and safe manner to reduce the risk of any injuries. Risk management is critical at every stage. Overall, I think about making sure the pipeline is properly constructed, meets current safety and construction standards, and provides value at an appropriate cost.

Ashmore: Safety is a primary issue, public safety as well as personnel safety and construction safety. Another issue is dealing with public involvement, as opposition groups can spring up overnight and can lead to security issues. From a regulatory perspective, making sure the contractor is implementing the conditions of the environmental permits and any other construction commitments the company has made throughout the regulatory process.

Marshall: Safety is always on my mind. My focus is on making sure everyone on the project team goes home to his or her family every night. Fluor is one of the safest contractors in the engineering and construction industry and we have a strong safety culture that is led by our leadership team. That culture permeates through the project – every worker, no matter their level, is empowered to stop work should they see an activity underway that they don’t feel is safe. Everyone takes ownership and accountability for their own safety and the safety of those around them.

Osborn: The safety of our people is of the utmost importance. Not just their safety in performing construction activities, but their safety and well-being in general (protection from protestors and opposition group tactics). Our personnel are family. We care about the health, job satisfaction, and well-being of our employees and their families.

P&GJ: In your experience what were some of the most unique obstacles that delayed construction?

Ashmore: Finding cultural resources during construction, retirement of individuals at an agency and having to start the approval process over and political climate changes.

Wolf: Every project is unique, but some of the common obstacles include permitting and environmental concerns, such as protecting endangered species. The economy is also important. During peak pipeline construction periods, it can be hard to compete for the contractors you need, but in a slow economy when money is tight the whole project may be postponed or put on hold. An even-keeled market is the best for our purposes.

P&GJ: Discuss your post construction processes and why they are important.

Ashmore: Pipeline approvals often come with post-construction conditions that may not always be implemented fully during operations and may require long-term monitoring at different intervals (1 year, 2 years, 5 years, even up to 20 years). Companies should be made aware of the locations of sensitive areas and timing windows for maintenance/surveying activities and reporting protocols. This can be done during the development of as-builts with GIS enabled activity reminders.

Wolf: A major goal is to produce a robust as-built documentation and turnover package. This can verify that project requirements have been met and that the project delivered the design and quality that were agreed to, with verified and traceable documentation. “Lessons Learned” are a critical part of the post-construction process so we improve on our next project.

Osborn: Post-construction “lessons learned” discussions help us understand what worked and what did not. This in turn makes us work safer, determine better methods, implement new controls, and further streamline our activities to become more cost effective, and thereby, more competitive. Crunching the data helps us understand where our costs are (relative to production rates), and allows us to recognize areas in need of improvement. Owners and their contractors should make this part of doing business.

P&GJ: What technologies can be used to lessen the environmental impact of a pipeline construction?

Wolf: There are many choices when designing and constructing pipelines. When you have a choice between open cut and a trenchless option like HDD, either approach could reduce the environmental impact based on the circumstances. You can also reduce the impact by sizing the pipeline properly, routing it to avoid sensitive areas, and using proper environmental safety and security controls: fences, hay bales, sandbags, and so on. The use of best practices is important regardless of which approach or technique is chosen.

Marshall: Environmental sustainability is a focus throughout the project. During the upfront studies, we route the pipeline to avoid environmental sensitive areas or areas with cultural significance to the greatest extent possible. During construction, we use a number of erosion and soil sediment control techniques. We also seek to minimize our construction footprint while ensuring the workforce has a safe work area.

Focusing on quality construction also prevents future environmental impacts. We use automated welding to produce high-quality, consistent welds. Electronic caliber tools and direct-current voltage gradient surveys can also confirm the integrity of the pipe that has been laid.

Ashmore: Drones can be used to survey areas with limited access (i.e., large wetland areas), sensitive resources (i.e., bird rookeries), and where legal, no-access properties exist. In addition, dry stream crossings and trenchless crossings such as HDD’s allow for a reduced ROW and minimizes the impact.

Osborn: Every year there are new advances in the oil and gas industry that help improve the overall safety of our projects. In particular, the means in which we collect and provide information to our teams in the field has made significant strides. To better prepare our team members for upcoming projects, we are using drones and other aerial photography to better assess terrain, water body crossings, and remote work areas before commencing work or placing individuals at these locations. Being able to better plan for these challenging areas allows the proper material, tools, and supplies to be available at location when needed.

P&GJ: How early in the process do you offer specifics to the public?

Ashmore: The level and intensity of proactive outreach depends on the client, but we always recommend a higher level of proactive outreach to mitigate the risk of delay or shutdown. The general “fear” is that the public will be empowered with too much information to stop a project. The reality is that too little information, or failed communications practices, often lead to greater risk of delay or shutdown than free-flowing informational sharing.

Osborn: This is normally driven by the particular state, county, or city we are working in. The regulations will mandate what we have to do in order to comply. It really starts at open houses by offering more information than just where the route will be, the size of the line, and the footprint. I would suggest offering what the construction methods will be, where the labor will come from, and what the impact will be to the local communities.

Wolf: Traditionally, we support the operator on a project and leave it to the operator to decide based on the sensitivity of the project, confidentiality, and other factors. In general, sooner is better so you can assess the issues, collaborate with stakeholders, and address any public concerns.

P&GJ: Which technical advances have contributed most to improving pipeline construction practices?

Ashmore: In general, GPS and aerial photography has revolutionized the industry and the movement is shifting towards utilizing advanced Drone technology for surveys and data analysis. Burns & McDonnell continues to advance our GIS based tools to capture live data for safety responses, landowner issues, and enables us to communicate in real time up and down the right-of-way, and send data directly to the home office from on-site, allowing decisions to be made almost immediately.

Wolf: From an engineering perspective, the Internet and the many new sophisticated mapping tools and smart devices give us access to much more data than we ever had before. We have ways to survey rivers, streams, rights-of-way, that allow better planning at an earlier stage of the project for construction planning and design. The industry should continue to leverage new technology to make improvements in safety, efficiency, quality, and affordability.

Osborn: Automation takes the human element out of the equation. The advances in the quality of materials has help reduce the failure/rework/replace rate in the industry. The steel manufacturers are doing a good job of turning out consistent product, and the owners are typically more demanding/rigorous in their selection of suppliers.

Automatic coating and welding systems are becoming more commonplace. Adding technology to a lot of the equipment makes it more precise and easier to operate. New products have been developed to protect the life and serviceability of the pipe such as pipe coatings, rock shields, and environmental ECDs (trench plugs and breakers, etc.). Cathodic protection and AC mitigation are becoming more sophisticated and tuned to the individual pipelines. Equipment telematics has played an important role and will continue to evolve. Telematics not only provide the location of the equipment but also track the operating performance and faults.

Direct pipe is another great advancement in the trenchless technology in dustry. It is a great solution when working in congested areas or critical crossings.

Marshall: There are a number of best practices that have improved pipeline construction safety. Fluor uses a number of behavior-based safety programs to drive a strong safety culture. For example, we have a Life Critical initiative that sharpens our focus on the precursors that can lead to serious injuries or fatalities. In addition to these programs that focus on behavior and engagement, we are

also using the latest technologies to enhance safety in the field, such as mechanized welding and backup sensors on heavy equipment.

Another advancement centers on the constructability of designs. Traditionally, contractors hand off work and the associated responsibility at the end of each phase, creating silos. This approach pushes unresolved issues to construction, creating delays and cost challenges in the most labor-intensive and costly project phase.

With the capabilities to take a pipeline from the initial studies to commissioning and start-up, Fluor integrates all phases of a project. For example, our construction teams are engaged in the design process, helping improve productivity when it is time to install those designs in the field. P&GJ

Comments