August 2017, Vol. 244, No. 8

Features

GIE’s Latest Challenge: World’s Longest Heat-Traced Pipeline

While Gulf Interstate Engineering (GIE) has no shortage of the kind of experience that comes from completing huge projects, its latest endeavor – the East African Crude Oil Pipeline (EACOP) – promises to offer at least a few new challenges along the way.

For one thing, once completed the 897-mile (1,443-km) Uganda-to-Tanzania pipeline, which should be in operation by the end of 2020, will be the longest heat-traced line in existence.

“What heat-traced basically means is they are going to make the pipe itself into a toaster,” said Doug Evans, president and CEO of GIE. “There will be continuous electrical cables attached to the pipe from start to end.”

The technology that will be used to heat the 24-inch pipeline has been in existence for years and has been used in other projects throughout the world. In fact, GIE did a similar project for Cairn India Ltd.

In the case of this insulated 24-inch pipeline, a power input point, to allow electricity for heating to come from the pump station, will be required every 30-60 km along the route. The voltage will be transformed from high to medium voltage.

“The technical concepts are still the same, it’s fairly simple regardless of the length,” Evans said. “But I think it’s important to note that the operation of this [heating technology] is variable. At the highest flow rate, electrical heating is not required. At the lowest flow rate, or in an upset condition, heating will be 24/7.”

GIE was chosen by Total East Africa Midstream (TEAM) and its partners, China National Offshore Oil Corporation (CNOOC) and Tullow Oil, to provide front-end engineering and design (FEED) services for the estimated $3.55 billion project early this year.

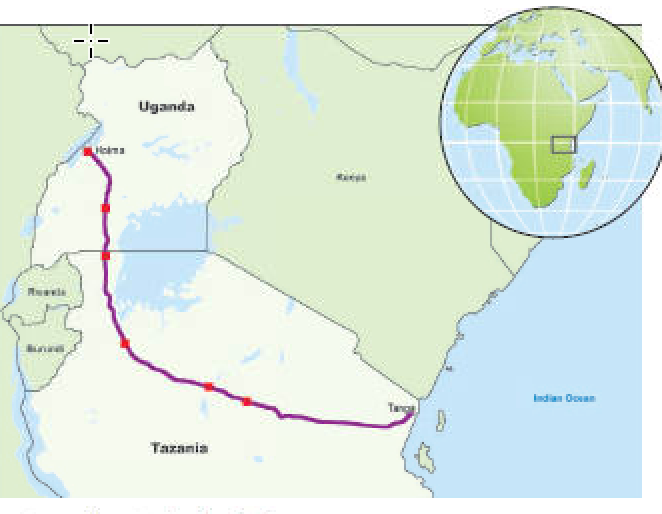

When completed the pipeline will run from Kabaale, Uganda in the northern part of Lake Albert, Uganda – where two production areas lie to the lake’s north and south – to Chongoleani, near the Tanzanian port of Tanga on the Indian Ocean. The overall system will accommodate a design flow rate of 216,000 bpd.

Other components of the EACOP project include:

- A maximum of six pump and heater stations along the route – up to the crossing of the East African Rift – along with a maximum of two pressure reduction stations.

- An onshore storage tank farm at Chongoleani, Tanzania, consisting of five 500,000-bbl heated storage tanks.

- A marine terminal pump station capable of loading a 1 MMbbl tanker within 28 hours.

- A 1-mile (1.7-km) offshore trestle-to-single-berth load-out platform.

In addition to the usual commercial and legal issues related to large transborder pipeline project, there will be some technical challenges.

“There are a couple of things to consider,” said GIE’s Mark Lamb, project manager for the EACOP. “You’re going up over the East African Rift area, so there are the seismic play and the fault lines. I guess the biggest challenge we have is the infrastructure and the logistics of moving equipment, material and manpower.”

According to Lamb, the Pipeline Project Team has undertaken surveys of the roads in the area, which primarily consist of tarmac and are in “pretty good shape” and murram (gravel), in advance of making improvements.

All in all, there will be road improvements along the route,” he said. “You don’t normally haul these kind of heavy loads on a repetitive basis, so it presents a challenge of establishing those improvements before you start receiving.”

Since late 2014, Gulf has assisted TEAM and its partners with conceptual design and other pre-FEED support services to evaluate the various pipeline route options and develop the selected Tanzania route. In April 2016, the Kabaale-Tanga route was selected by the Ugandan government.

The FEED phase will address a number of additional technical and execution planning challenges, including local power generation options, planning for pipe deliveries as well as coating and storage in advance of pipeline construction, construction of access roads, camps and other logistical requirements.

GIE will perform the FEED work at its Houston office, under the supervision of the Pipeline Project Team, which includes representatives from the oil companies and the two governments.

“You are bringing a lot of different cultures together, and it’s truly a collaborative effort,” Lamb said. “I’ve been at this for a number of years and I’m very pleased, we at Gulf are privileged to be part of this project. I don’t think I’ve ever been involved in a project quite so challenging – they come along about once every decade.”

GIE will complete the FEED work – which involves about 85 engineers and technical specialists – this year. Preparatory work for the pipeline is targeted early 2018, with heavy construction expected to take place in 2019 and 2020.

“Gulf has been very fortunate to have participated in most of the world’s big name projects in the U.S., South America, Europe, Russia, etc., and this is another one of those types of projects,” Evans said. “I know it’s an over-used term but this is going to be a world-class project.”

Comments