May 2017, Vol. 244, No. 5

Features

Rooting Out Trouble Before It Happens

For years, utilities like PSE&G have used pigging devices to inspect the inside of gas pipes for corrosion, damage by excavators and other signs of trouble that could cause leaks and, in extreme cases, explosions.

A pipeline pig normally is propelled by the speed of the gas flowing through the transmission main while sensors measure corrosion and any thinning of the pipe wall.

“PSE&G maintains about 61 miles of gas transmission pipelines that serve our system,” said George Ragula, distribution technical leader for gas asset strategy. “In about 30 of those miles, we are unable to use a standard pig because the flow of gas is too low to propel it. We need a more advanced way to perform inspections of these pipes to meet federal safety guidelines.”

The technology was developed through a multi-year NYSEARCH project with funding from PHMSA and NYSEARCH member companies across the United States. Through NYSEARCH’s leadership of the consortium, PSE&G and other utilities funded development of a new robotic “smart” pig called Explorer – a self-propelled, more flexible piece of equipment that can easily navigate a pipeline’s twists and turns. Manufactured and operated by Pipetel, the robot can provide detailed information about the pipe’s condition.

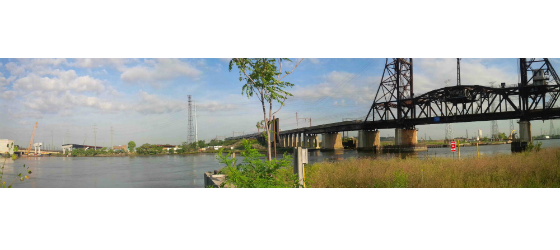

“PSE&G is the first utility in New Jersey to use this new robot, which recently inspected 2.2 miles of pipeline between Jersey City and Kearny, including under Newark Bay,” Ragula said. “Thankfully, the robot didn’t detect any immediate issues with the pipe, which was installed 40 years ago.”

Ragula said PSE&G will use the more advanced pipeline pig to inspect most of its 30 miles of transmission pipes in the future. “Because it provides measurable data, this new robot will help PSE&G ensure that its infrastructure is as safe and reliable as it can be,” he said.

Comments