March 2016, Vol. 243, No. 3

Web Exclusive

Williams Advances Unique Position in Canada with Startup of Second Offgas Processing Plant

Williams today announced the startup of its second offgas liquids extraction plant, a key asset in the company’s Canadian midstream and petchem complex. The new plant boosts domestic production of petchem feedstocks and significantly reduces emissions in the oil sands production process while recovering valuable natural gas liquids (NGLs) and olefins.

Serving an upgrader facility north of Fort McMurray, Alberta, the plant is designed to reduce emissions of carbon dioxide (CO2) – a greenhouse gas – by an average of approximately 200,000 tonnes per year and reduce emissions of sulphur dioxide (SO2) – a contributor to acid rain – by an average of approximately 2,800 tonnes per year.

Williams is the only company extracting and fractionating NGL/olefin mixes from oil sands upgrader offgas. Its first plant of this kind serves the upgrader of another third-party oil sands producer. The two plants recover ethane, propane, propylene and other liquids from the upgraders’ offgas streams. Williams then transports, fractionates and markets the products.

“This new offgas plant at the upgrader is helping the environment and creating value from what was previously a low-value oil sands resource,” said David Chappell, president, Williams Energy Canada. “It adds to our world-class, long-life complex of assets with a highly sustainable competitive advantage in a key North American energy hub.”

The plant increases by 60 percent the amount of NGLs produced by Williams in Canada to a total of approximately 40,000 barrels per day. At peak construction the project employed 1,200 workers and more than a dozen permanent staff operate the facility.

Alberta’s Minister of Environment and Parks, Shannon Phillips, who is also Alberta’s Minister Responsible for the Climate Change Office, praised Williams for improving both the environment and the economy.

“We applaud Williams Energy Canada for their efforts to reduce greenhouse gas emissions, add value to our resources and create good jobs here in Alberta,” said Phillips. “The startup of this plant is a testament to the innovation of Alberta’s energy industry.”

The Fort McKay First Nation, whose traditional land is nearby the new facility, stated: “The Fort McKay First Nation appreciates that the Williams facility is expected to have a positive impact on the local air shed by reducing carbon and sulphur dioxide emissions. This will mean a healthier future for our people and for the environment. We are pleased to support companies that are putting the environment first and are respectful of our traditional lands.”

Following extraction at the upgrader, the NGL/olefins mixture will be transported by Williams’ recently extended Boreal Pipeline to Williams’ expanded Redwater Olefinic Fractionator (ROF), the only olefin/paraffin fractionator in Canada. Most of the propane is expected to feed Williams’ planned propane dehydrogenation (PDH) facility near Edmonton for the manufacturing of polymer-grade propylene. As previously announced, a private equity global petrochemical group has executed a long-term contract with Williams for 450 KTA of the propylene for polypropylene production.

“This developing complex will greatly reduce Canada’s current dependence on polypropylene imports while spurring domestic manufacturing and strengthening the region’s economy,” said Chappell.

Pioneering Emissions Reductions

The offgas processing that Williams pioneered significantly reduces emissions at its customers’ oil sands production facilities. Williams captures and processes a rich NGL/olefins mixture that would normally be burned as fuel by the oil sands producer. The producer instead burns methane that Williams provides in exchange for the NGL/olefins mixture.

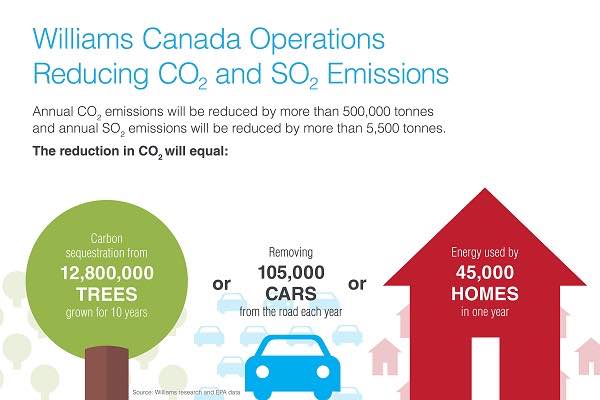

The company’s two offgas processing plants in Canada together will eventually reduce annual CO2 emissions by more than 500,000 tonnes and annual SO2 emissions by 5,500 tonnes. The CO2 emissions reduction is equal to taking 105,000 cars off the road every year and equal to the total yearly energy needs of 45,000 homes. To achieve the same CO2 reduction through sequestration, 12.8 million seedlings would need to be grown for 10 years. If offgas from all oil sands upgraders in Alberta were captured and processed, CO2 emissions would be reduced by 1 million tonnes in total each year.

Comments