December 2014, Vol. 241, No. 12

Features

Navigating The Petroleum Measurement Perfect Storm

A “boom paradox” is creating the perfect storm in liquids hydrocarbons measurement. Baby boomers hired during an earlier peak in the industry are retiring. Exiting with them is vast knowledge in areas such as measurement. Thanks mainly to shale plays, the industry is booming and new players are entering the market. Simultaneously, the industry is in the process of implementing significantly updated measurement standards. Can measurement operations ride out the storm?

The baby boomers were hired during the good times that lasted into the early 1980s. When oil prices dropped from $35 a barrel to as low as $10, companies responded with hiring freezes and layoffs that stretched well over a decade. An industry that had a peak of 860,000 jobs in 1982, according to the Bureau of Labor Statistics, shed more than a half million of them by 2000.

That created an age gap in workers, which now that members of the baby-boom generation are heading for the doors, is leaving the industry with no one to replace their knowledge and experience. Schlumberger Business Consulting has projected that by 2016, retirements of baby boomers would mean a deficit of 15,300 “experienced petro-technical professionals,” about 19% of the workforce.

A recent analysis from recruiting firm Russell Reynolds and Associates gathered input from 30 of the top oil, gas and power companies and found 61% of executives in those companies are older than 52 and eyeing retirement. In short, there are more executives and professionals ready to retire than there are those ready to take their places. And the ones who are stepping in don’t have as much experience.

New Players

As the industry scrambles to train replacements for the departing boomers, interest in shale plays is bringing two new groups of participants into the market: start-up trading companies and natural gas companies.

The trading companies don’t run operations such as production or pipelines and lack staff measurement experts. They are unfamiliar with liquids measurement calculations and how to implement them. At the same time, traditional natural gas operators are expanding into liquids in order to take advantage of the high oil prices relative to gas prices. These gas operators are quickly realizing that there are many differences between natural gas measurement and liquids measurement.

Billions of dollars per day of liquid hydrocarbons are being traded and uncertainties over calculations need to be minimized.

While these changes are taking place, the American Petroleum Institute (API), Gas Processors Association (GPA) and American Society for Testing and Materials (ASTM) have created and updated numerous standards that address the methodology and techniques for accurate measurement of hydrocarbon fluids.

These fluids range from natural gases to light natural gas liquids to heavy crude oils and petrochemicals. The industry standards provide guidelines on static and dynamic measurement, primary meter selection and operation, meter-proving procedures and the fluid’s physical property correction factors, which are used to state volumes and densities to contractual conditions.

There is much history behind the measurement and calculation standards. Correction factors to account for the thermal expansion of liquid hydrocarbons date back to 1916 when they were published by the National Bureau of Standards. Since then, standards have been updated and many new ones have been introduced.

In 2004, API released a new set of physical property tables that includes, among a broad range of updates, pressure and temperature effects on density. The 1980 tables had considered density and temperature but not pressure. By incorporating pressure correction, the 2004 standard now encompasses three-dimensional tables.

Since 2002, there have been numerous updates to standards including metering and physical properties. A major update to Chapter 11, Section 1, “Temperature and Pressure Volume Correction Factors for Generalized Crude Oils, Refined Products, and Lubricating Oils,” is reverberating throughout the industry. For those fluids, the standard establishes a procedure by which density measurements taken at any temperature and pressure can be corrected to an equivalent density at base conditions.

Although the update was effective in 2004 with a revision in 2007, grandfather clause effects have delayed implementation to the point that even today it is still considered new.

![]()

Implementation Of New Standard

As the boomers depart, along with their expertise in the tables through 1980, how do the new players on the scene implement the 2004-2007 standards?

Complicating matters is that API MPMS 11.1 does not address all the hydrocarbon fluids. Most LPGs and NGLs are less dense than the liquids covered by this standard. liquefied natural gas (LNG) is, as well. Implementers must look to other API MPMS chapters or sources, such as the GPA Technical Publication TP-27 for hydrocarbons such as the LPGs and NGLs.

Meanwhile, an increasing number of producers and midstream operators must track multiple fluids, natural gas, NGLs and heavier liquids – in their systems. They use a variety of meters ranging from the traditional orifice, positive displacement and turbine meters to newer technologies, including cone, Coriolis and ultrasonic. Sitting on top of those meters is an ever-expanding range of meter correctors, gas and liquids flow computers.

An operator that deals with multiple fluids must consolidate all the information from such disparate technologies, verify the accuracy of the data, apply any required fluid quality samples and then recalculate data as needed. Once that is complete, the user can then perform an accurate, systemwide inventory balance to look for any additional issues or missing data. That means implementing practically the entire API MPMS and more. Are the baby boomer replacements, natural gas companies and traders up to the challenge?

A group of industry experts has recognized the demand for accurate tracking in such operations. To meet the emerging needs of oil and gas producers and midstream operators, measurement software specialists have partnered with several users to develop the capability to manage natural gas, NGLs, petrochemicals, crude oils and refined products within a single application.

Measurement Automation

The latest-generation measurement applications automate the calculations and processes that are described in the API MPMS, as well as additional documents and standards, such as those from the GPA. This allows the industry’s new measurement personnel to bypass a formidable effort to implement the various standards and calculations with in-house applications. By avoiding a considerable software development effort, measurement personnel can instead focus on optimizing their business operations.

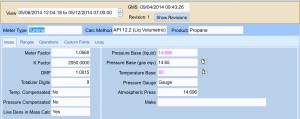

Liquids flow measurement applications must accommodate all the meter types in API MPMS Chapter 5, for which many changes were made in 2005. In an example application, a “characteristic editor” provides the user access to virtually every meter configuration item that is required in measurement calculations.

To convert actual density, pressure and temperature to standard conditions, measurement applications must meet all requirements in Chapter 11, “Physical Properties Data,” and the related Chapter 12, “Calculation of Petroleum Quantities.”

As an illustration, a “products editor” allows users to set up the products that flow on liquid meters and tickets. Setting up a product requires knowing which API table or calculation is to be used for calculating the correction for the temperature of the liquid (CTL) and the correction for the pressure of the liquid (CPL).

Volume editing is a classic application that is derived from circular chart measurement processing. Most information is uploaded from flow computers that are installed throughout the production, pipeline or terminal system. Since missing information may need to be filled in or measurement errors corrected, the editing function remains an important feature that continues to evolve.

Users must be able to view and edit all measurement points including pressure, temperature, density, mass and volume as highlighted in the next example. Once edits are complete, the analyst needs to be able to have the volume and mass recalculated for reporting and to be sent to downstream accounting systems. Applications incorporate manual processes, such as sampler information for accurate calculation of corrected mass and volumes.

Once a measurement error has been corrected, the measurement application can re-state pressure, temperatures, volumes and mass anomalies that have been resolved and create a full audit trail. Contemporary applications meet and exceed the audit trail requirements in API MPMS Chapter 21.1 and 21.2.

Conclusion

Built in to contemporary measurement applications software is the vast expertise that, in the past, was reserved for the most accomplished professionals. All the static and dynamic measurements, metering technologies, meter proving, physical properties, flow calculations, calibration, data processing, auditing and verification processes are included.

By automating all the calculations and processes that are described in the API MPMS, as well as additional documents and standards, such as those from the GPA, such software provides a comprehensive, petroleum measurement solution that a new generation of professionals can rapidly put to work.

Author: Michael Squyres has 25 years of experience in designing and developing gas and liquid measurement applications. He has worked directly with SCADA, EFM and standards organizations on validating, calculating and reporting measurement data. Squyres serves as an instructor for the American School of Gas Measurement and Technology, International School of Hydrocarbon Measurement, and many other industry-related schools and short courses.

Comments