August 2014, Vol. 241, No. 8

Features

Overcoming Pitfalls Of Installing Pipeline Integrity In Russia

Pipeline systems are an extremely safe method of transporting hydrocarbons. However, like any engineering structure, failure remains a possibility, which could result in serious consequences for the surrounding population and environment.

As a result, risk-based integrity management systems are increasingly being used to ensure that pipelines are repaired and re-inspected in a safe and cost-effective manner. Risk management is a methodology for ascertaining the likelihood that an event will cause harm to people or the environment. Essentially, it provides strategies, processes, resources and tools to monitor, recognize, and deal with a risk event.

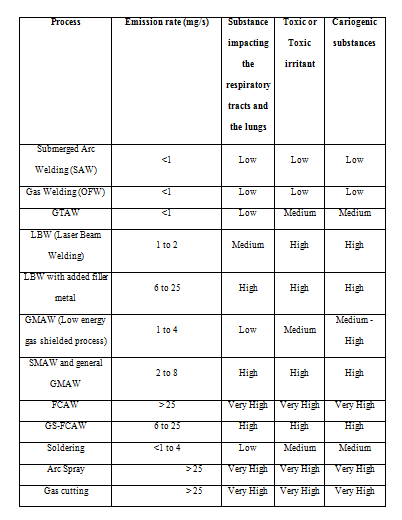

Various techniques are available to evaluate risk factors for different threats and failure scenarios. These range from descriptive qualitative based on engineering judgment. (For example, ASME B31.8S and API 1160, which generate relative risk values through to detailed mathematical analyses in fully quantitative assessments that express risk in absolute terms, such as IGEM/TD/2 and PD 8010-3:2009 (Figure 1).

It should be noted, however, the degree of complexity used does not necessarily reflect the accuracy of the results. In most cases, there is insufficient information to justify applying a fully quantitative approach to assessing risk, other than in specific cases such as a failure investigation.

In Russia, early pipeline risk models were often based on simple scoring systems and were routinely used to assist detailed design at specific pipeline locations. The ongoing development of the assessment methodology, the knowledge of the application of risk assessment to pipeline design and operations, and the increase in availability and processing power of computers led to the development of semi-quantitative risk methodologies, which apply weighting factors to various threat parameters.

Due to the growing availability of quantitative data, such as inline inspection (ILI) information and geographic information systems (GIS) data, and the development of methods for the prediction of pipeline failure frequency and consequences, Russian pipeline operators have more opportunities to use quantitative risk assessment (QRA) models.

The development of risk-based approaches in Russia was established by pipeline operators mostly as internally recommended guidelines for specific cases, not as part of pipeline integrity management systems (PIMS) strategy. The potential in risk assessment was only recognized by Russian authorities in 2013.

The prime mover of this change were amendments to federal law on industrial safety of hazardous production facilities (116-FZ), ratified in March 2013. According to this law, entities operating hazardous production facilities are required to implement safety management systems and ensure adequate functioning. As highlighted in 116-FZ, the main tasks of the safety management systems are:

1. Identification, analysis and prediction of risk of accidents at hazardous production facilities and related threats.

2. Planning, implementation and timely adjustment of measures to reduce the risk of accidents at hazardous production facilities.

In connection with these changes in Russian legislation, an active process of harmonizing Russian and foreign standards, technical rules, industry codes and best practices, developed by international organizations, such as ISO, IEC, API, ASME and BSI is underway.

A group of national standards for analysis and evaluation of risks (GOST) (GOST R 51901.11, GOST R 51901.12, etc.), has been developed in accordance with international standards IEC (IEC 61882:2001, IEC 60812:2006, etc.), revealing generally accepted techniques, such as HAZOP/ HAZID, FMEA, quantitative risk assessment (QRA), can serve as an example.

In addition, in the cases with an absence of harmonized local standards, Russian legislation includes provisions allowing the application of foreign equivalents, provided adequate justification is given, such as experience applying this standard to similar facilities abroad.

To summarize the trends identified above, the usage of risk-based integrity management systems for pipelines is increasing in popularity, and changes in Russian legislation are encouraging operators to practice more widely accepted risk assessment approaches.

To support these trends, this article overviews two PIMS implementations in Russia – at Gazprom and Zapsibtransgaz (ZSTG) – involving aerospace monitoring and technologies (AMT) specialists. The main difference between these two projects is that Gazprom is developing its own PIMS and ZSTG uses international software and methodologies.

PIMS Implementation At Gazprom

Since 2009, Gazprom has been actively working on the development and implementation of its integrity management system for gas transportation system of more than 160,000 km of pipeline, 238 compressor stations and 25 underground gas storage facilities.

The main motivation was Gazprom’s desire to ensure secure transportation and storage of gas, along with environmental and industrial safety, while operating gas transportation facilities. The company also wants to centralize its decision-making processes concerning repair and maintenance actions. To date, within the framework of the project, the following milestones have been realized:

• A unified basis for methodical and procedural rules defining approaches and principles of management has been established. This includes methods for calculating reliability and risk factors and statutory documentation of assigned repair methods.

• Risk management algorithms have been developed and tested.

• Prototype software was created for key performance indicators (KPI) calculations and development of effective inspection, maintenance and repair plans.

The methodological framework for risk analysis used in the project is based on standard guidelines for hazardous production facilities of Gazprom gas transmission enterprises (STO Gazprom 2-2.3-351-2009), which contains a detailed description of sequential stages of quantitative risk analysis (QRA) in relation to pipelines and underground storage facilities of Gazprom.

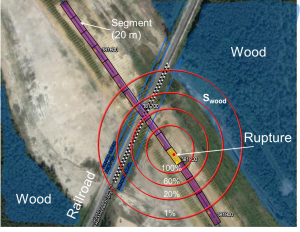

The standard addresses expected frequency of failure, identification of failure scenarios, and impact (Figure 2) and assessment of adverse effect on human beings, technological equipment and the surroundings.

It should be noted that comparative analysis of risk calculations results are based on Russian standards, including STO Gazprom 2-2.3-351-2009, and industry-recognized codes show a satisfactory fit. However, according to subject matter experts, the methodology presented in STO Gazprom 2-2.3-351-2009 was tailored to the actual results of accident investigations at Gazprom main pipelines and thus provide a more reliable result.

The advantage of using QRA is it is a structured and logical approach that quantifies the risk level and allows informed decision-making. However, its disadvantages are that it is complex and requires a large amount of input data. In this regard, the first priority within the PIMS project at Gazprom was data gathering and data migration of the massive amount of technical and spatial information into the database using a unified data model.

Despite Gazprom developing its own PIMS, the methodology, the data model and software is consistent with the generally accepted concept of PIMS.

PIMS At Zapsibtransgaz

ZSTG operates more than 2,500 km onshore pipelines in the Tyumen region of Russia. It supplies gas and NGL to large petrochemical and gas processing plants of SIBUR Holding.

In response to financial, resource and logistic constraints, its management of optimized costs of diagnostic and repair works by implementing a cost-effective maintenance and rehabilitation program. In 2012, ROSEN Integrity Solutions and Aerospace Monitoring & Technologies initiated the implementation of its asset integrity management software (ROAIMS) at ZSTG.

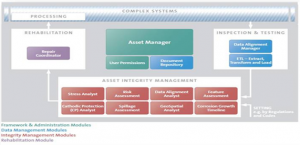

ROAIMS is a collection of interoperable software tools for maintaining assets in a reliable, safe and cost-effective condition. It is designed to allow an operator to visualize, explore and analyze complex information.

Equipped with comprehensive risk analysis functionality, ROAIMS can identify the most significant immediate and future threats, and allow mitigation to be captured and applied, and comprehensive scenarios to be automatically or manually constructed and compared. This flexibility allows individually selected relevant modules to create personalized software systems.

ROAIMS was designed to follow ROSEN’s “control loop” approach to asset integrity (Figure 3). The integrity loop used as part of this approach is broken down as processing, inspection and testing, asset integrity management and rehabilitation.

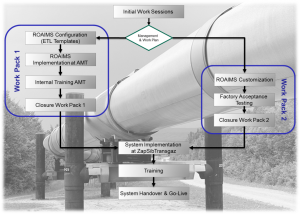

The scope of work (Figure 4) within the PIMS project was divided into two “Work Packs,” which were planned and executed in a synchronized manner. The initial phase of the project represents the implementation of the software into the AMT IT environment to allow for proper data collection and integration.

Software adaptations at this stage were limited to providing extract- transform-load (ETL) templates and the required database modifications to store all information along the pipeline route.

Parallel to this initial phase, ROSEN and AMT fine-tuned the customization requirements in terms of the work order management system interface and translation to Russian language.

Following the successful execution of these activities, the results were consolidated alongside the testing and release process with the final goal to “go-live” in compliance with the specifications. ROSEN technical support handles the Level 2 inquiries from AMT during the warranty period.

The pilot project (900 km) included:

• Representation of a complex branched network of pipelines (natural gas, NGL).

• Data integration of more than 30 years of design and operation data. (Migration was done manually, according to the definitions and restrictions governed by the pipeline open database standard (PODS) model.

• Integration of a variety of diagnostic results (e.g., the results of inline inspection presented by Weatherford, Tuboscope, NDT, ROSEN, Gazpriboravtomatikaservis, Neftegazkomplektservis and Spetsneftegaz).

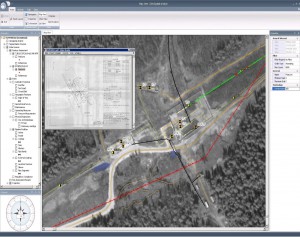

• Development of a corporate GIS for ZSTG’s pipelines that included technical information on pipelines as well as analysis of technical condition and risk (Figures 5, 6).

• Retrospective statistical analysis of available pipeline data (Figure 7).

• Software customization and interface (data modeling, software configuration, software translation to Russian and interface with work order management system).

• Risk-model configuration based on satellite imagery interpretation (geotechnical diagnostic).

• Turnkey implementation of the project, including the supply of high-end equipment for the software and customer training.

Customization for generally recognized quantitative pipeline risk models should be separately considered. Generally, such risk models are based on U.S. and European failure statistics, provided by governmental and industrial organizations (including European Gas Pipeline Incident Data Group (EGIG), United Kingdom Onshore Pipeline Operators Association (UKOPA), U.S. Department of Transportation: Pipeline and Hazardous Materials Safety Administration (PHMSA), and so forth). This does not necessarily apply to other countries.

The range of statistical data that affects the probability of failure includes that from local, state and federal oversight, local climate and geography, as well as socio-economic and geopolitical factors.

In Europe, the dominant failure mode is third-party damage, whereas in Russia corrosion (particularly stress corrosion cracking) predominates, while third-party damage is rare because of low population density in transmission areas of most pipelines.

Consequently, estimates of baseline probability should take into account local experience and the relevance of the data used. On this basis, a hierarchy of preferred data would be:

1. Failure statistics from an operator’s own pipeline network.

2. Failure statistics from national bodies, such as a state regulator or research group.

3. Failure statistics from a regional research group or intergovernmental organization.

4. Regional failure statistics, such as North American experience with additional contributions from local subject matter experts (SMEs).

5. International failure statistics with additional contributions from local SMEs.

6. Estimated probabilities of failure made by local SMEs.

The results of the pilot project (900km of pipelines) allow the user to manage the risks associated with its pipeline in a way that is flexible, rational, consistent, and can be readily understood by others. It also allows rationale for decisions regarding inspections to be recorded, and new users to quickly learn the key safety issues for the pipeline.

Conclusions

PIMS is the process of managing pipeline operational risk and mitigating it effectively to ensure pipeline assets are maintained in safe and reliable condition.

Pipeline standards and regulations in Russia are increasingly requiring operators to use risk management. The use of QRA for the safety evaluation of pipelines is now accepted practice in Russia and it is used at the design stage of major pipeline projects.

In the case of two key Russian gas and petrochemical companies, despite the differences in detail, both PIMS projects are driven to improve the accuracy of pipeline integrity estimations, and to justify decisions based on these through wider application of quantitative methods for analysis and evaluation of operational risk. The PIMS systems were implemented and successfully tested. As a result similar systems are now being deployed by other companies.

There is a growing trend toward applying generally accepted practices in the implementation of PIMS in Russia, guided by the requirements of the documents Rostekhnadzor, Russian Ministry of Emergency Situations and Gazprom.

Lastly, despite the ongoing coordination with international standards, it is necessary to adjust risk models and algorithms in accordance with local (Russian) needs, and, therefore, the estimation of the baseline probability must be taken into account, along with local experience and the relevance of the data used.

Acknowledgement: This article is based on a presentation at the 26th International Pipeline Pigging and Integrity Management Conference sponsored by Clarion Technical Conferences in Houston, TX Feb.10-13 2014.

Comments