June 2014, Vol. 241, No. 6

Features

Polyethylene Gas Pipeline Systems: Designing Out Rapid Crack Propagation

Polyethylene (PE) has revolutionized low-pressure gas distribution pipeline design on a global basis. PE’s combination of flexibility, ease of joining, lack of corrosion, long-term durability and lower installation cost make it the gas transporter/operator’s preferred material.

In order to maximize benefits gas transporters continue to push the PE design envelope, using pipe in more demanding applications, such as larger pipe diameters and higher operating pressures.

This article looks at the increased risk of rapid crack propagation (RCP), referred to as a “fast brittle fracture,” or by the construction industry as a “linear split” that must be considered when increasing the diameter and wall thickness of PE pipe. A review of the International Organization for Standards (ISO) full-scale test method used to determine RCP performance and the need for type test verification and certification are also discussed.

RCP is caused by the forced introduction of a brittle crack into a material, where a combination of material quality, temperature and internal pressure determine how far the crack will propagate along the pipe, the point at which the crack tip is blunted and the fracture event arrested.

Theory

RCP of PE pipes is initiated at defects within the pipeline by sudden mechanical shock such as a high-velocity impact from excavation equipment or a pipeline pressure pulse. Once initiated, ruptures can travel at high speed (100-300ms-1) along the length of the pipe over significant distances.

RCP is generally of concern in piping systems that are used to convey compressed gases. The rapid energy dissipation from a compressed gas provides the energy required to sustain crack growth. At a critical speed, the crack will become unstable, branching in a sinusoidal pattern, until it slows and stops. Alternatively, a crack may be arrested at a point where a change in cross-section occurs or a flange connection breaks the continuity.

RCP is dependent on several factors:

• Pipe diameter – as diameter increases, RCP risk increases

• Operating pressure – as stress in the pipe wall increases, RCP risk increases

• Operating temperature – as temperature decreases, RCP risk increases

• Material properties, such as fracture toughness, impact strength and fatigue resistance

• Pipe-processing history – residual stress

Effect Of Failure

Several instances of RCP have occurred in the United States and continental Europe, but gas companies are reluctant to share information on these and details are scarce. The potential for uncontrolled large-scale release of gas could be disastrous, and hence demonstrates the criticality and importance of assessing this material performance characteristic.

RCP of PE pipes can have varying responses depending material properties and pipe geometry. Simulated RCP failure of buried PE pipe show that the failure event can be explosive, generating significant pressure waves (Figure 1). During pipe fracture, significant fragmentation may occur, which can travel at high velocity over distances of 50 meters.

Typical features of an RCP crack are a sinusoidal crack path along the pipe (Figure 2), while bifurcation of the crack into two directions may also occur. RCP can also propagate through butt fusion joints, whereas research suggests cracks are arrested by electro-fusion couplers.

Research Into RCP

The development of high-pressure steel transmission pipes has resulted in intensive research into the mechanism of RCP providing a comprehensive understanding that can be applied to PE networks.

In the early 1970s, the threat of RCP restricted the use of pipe greater than 315 mm diameter. In order to solve this problem, British Gas, based on its extensive research of crack propagation in steel pipelines, developed a test methodology to calculate critical pressures below which any initiated fracture would not propagate within a known pipe diameter. Using an appropriate safety factor, it was then possible to identify safe operating pressures.

The research gave rise to the full-scale PE RCP test facility and methodology, the latter of which was to become the ISO 13478 standard for RCP pipe testing. This test is considered to be the ultimate reference for assessing RCP performance.

The original test facility (see Figures 5 & 6) is now owned and operated by DNV GL at its Spadeadam Test Site, providing for further analysis of the phenomenon of RCP and verification and certification for global manufacturers of PE materials, pipe and PE pipeline operators.

Testing

DNV GL’s full-scale RCP test facility at Spadadam consists of a concrete trench equipped with a cooling unit to condition the test sample at any temperature from ambient down to -15° C and a large steel pressure vessel to simulate a pressurized gas network.

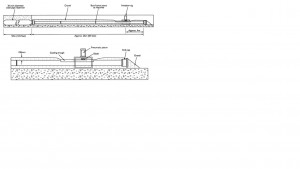

The test involves the initiation of a crack in a 24-meter length of PE pipe. The test pipe is first fused, stringed and clamped in a trench with one end connected to the gas reservoir. The pipe is then buried in gravel, cooled to a reference temperature of 0o C. (Figure 5).

Following pressurization, a blade driven by a fast-acting pneumatic piston is used to initiate the crack in an area of the pipe (Figure 6). The make-up pipe can be extruded with a less-resistant resin in order to ensure this initiation. To ensure initiation of a brittle crack, a groove is also machined in the initiation zone, which is cooled under the glass transition temperature of PE using a methylated spirits and solid carbon dioxide mixture prior to testing.

Repeating the experiment at different levels of pressure determines at a given temperature the characteristic critical pressure beyond which the crack propagates over more than 90% of the pipe length.

PE materials used for construction of natural gas networks are of the third-generation type with highly elevated mechanical characteristics: the European draft standard for PE gas networks provides a maximum operation pressure up to 10 bar for such materials. Since the risk of rapid crack propagation becomes more critical at growing pressures, the importance increases to control this phenomenon thoroughly.

Hence, gas industry standards for PE gas pipelines – ISO 4437, EN1555, GISPL2 – include an RCP requirement. The pass criteria for RCP is:

Pc > 1.5 x MOP

Where:

Pc = critical pressure, psig

MOP = maximum operating pressure, psig

MOP is determined from the standard formula knowing the pipe standard dimension ration (SDR), the MRS (minimum required strength) and C (design coefficient). Once the gas company has determined its MOP, the RCP requirement is the critical pressure of the pipe must be (at least) 1.5 times the MOP.

This 1.5 factor is due to the pre-commissioning leak test pressure, which is generally done at 1.5 times the MOP. Many RCP failures actually occur during the leak test, because this is when the pipe sees the highest internal pressure, and is most susceptible to RCP.

To determine comprehensive and accurate operating pressures to permit the usage of larger diameter PE pipes at higher pressures for a range of pipe sizes and SDRs over the full temperature range, a series of full-scale RCP tests was implemented.

These tests have made it possible to calculate the safe operating pressure for each pipe diameter and wall thickness over a range of operating temperatures from -20oC to + 20oC. This research made it possible to design pipeline operating pressures such that the risk of RCP occurring is minimized within the UK PE distribution network.

To date, RCP has not been observed as a failure mode in the UK. This is a testament to the engineers that have worked to understand this failure mode and have created appropriate operating codes that prevent the pipes being operated in conditions where they would be susceptible to RCP.

Conclusion

RCP is not the result of inferior PE or pipe quality; rather, a combination of intrinsic material characteristics, the type of impact or damage, the pipe size and SDR, temperature and the presence of pressure in the pipe.

DNV GL strongly advises the operators of PE gas pipe distribution systems to determine whether pipe materials used within their systems have been fully tested to determine the RCP critical pressure level. With robust verification and certification testing in place, RCP of PE pipelines can be eliminated, giving the necessary assurance in the integrity and safety of the pipeline asset in the event of third-party damage or poor installation.

Comments