June 2014, Vol. 241, No. 6

Features

Breaking Down Quad-O Regulations, Compliance Needs

Just as onshore production methods change and evolve over time, so too do environmental regulations. On Aug. 16, 2012, the Environmental Protection Agency (EPA) published final regulatory updates specific to onshore oil and natural gas production that span from well completion to transmission. Deciphering and gaining a better understanding of these regulations will remove costly compliance pitfalls during normal operations.

Quad-O, short for Code of Federal Regulations (CFR) 40, Part 60, Subpart OOOO, is the current buzz word around onshore production. After being sued in January of 2009 for failure to review existing regulations, the EPA was required by consent decree to review and update rules that had not been revisited since hydraulic fracturing reinvigorated production, especially in unconventional formations. The U.S. District Court, for the District of Columbia, deemed that this new type of drilling created a “new source” for volatile organic compounds (VOCs), setting the stage for the EPA to reexamine emissions standards.

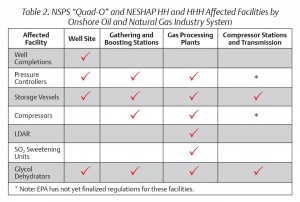

The EPA developed New Source Performance Standards (NSPS) that defined what processes and equipment are affected and quantified necessary emission reductions. The new regulations apply to all onshore oil and gas facilities constructed, modified, or reconstructed after Aug. 23, 2011. Affected facilities include: hydraulically fractured gas well completions, continuous bleed pneumatic controllers, reciprocating and centrifugal compressors, storage vessels, equipment leak detection and repair, as well as SO2 sweetening units.

Quad-O states each facility constructed or modified after Aug. 23, 2011 must meet the published guidelines, but to allow producers to implement adjustments in accordance with specific regulations and timelines for compliance assigned to each facility.

Well Completions

The EPA has delivered a two-phase process around controlling VOC emissions during completions that began for wells drilled or modified after Aug. 23, 2011.

• Phase 1 (before Jan 1, 2015): VOC emissions to be reduced by either flaring devices or reduced emission completions (RECs), also known as green completions, to either burn or capture natural gas that would otherwise escape to the atmosphere. Flaring is subject to local and state regulations.

• Phase 2 (after Jan. 1, 2015): VOC emissions to be reduced by using RECs and capturing natural gas during the flowback period – making it available for sale or use.

Re-fracturing existing wells drilled before Aug. 23, 2011 to stimulate production and using flaring to reduce VOC emissions will be considered modifying the well and place the full well site and all of its facilities within the scope of Quad-O. An incentive of using RECs for existing wells is that the re-fracturing of an existing well will not “modify” the well, thus leaving the well-site and its facilities out of the scope of Quad-O. Therefore, onsite equipment could remain grandfathered in and need not be reviewed for compliance.

EPA notification and reporting of hydraulically fractured wells has also been addressed. At least two days before completion procedures begin, unless the state has an earlier notification requirement, the EPA must be informed of the well’s geographical coordinates and the date the completion procedures will begin. Owners and operators of the well to be completed can notify the EPA by email.

An annual report detailing all well site completions, which has been certified as accurate and truthful by a senior official from the owner or operating company, must be submitted to the EPA. The report can take two forms:

• Traditional report: This covers information on affected facilities at the well site. Compressors, pneumatic controllers and storage tanks that have been added or modified during the year would be considered affected facilities.

• Alternate report: This is a list of well completions supplemented with a digital photo of each individual green well completion. The photo must be taken during the completion process with embedded geographical coordinates of the well site.

All reports must specify deviations to Quad-O regulations experienced during completion.

Some exceptions to Quad-O for new wells include exploratory, delineation and hydraulically fractured low-pressure wells. Exploratory and delineation wells are exempt due to the typical remote location and lack of access to a natural gas pipeline network. Low-pressure wells can be determined by using a formula published in the Quad-O regulation.

Pneumatic Controllers

Reliable pneumatic equipment has been the backbone of well-site automation for decades. Pneumatic controllers typically bleed pressurized gas to atmosphere to measure and maintain process variables, such as level, pressure and temperature. Most well sites use produced natural gas to power pneumatic controllers; therefore, many pneumatic controllers contribute to the release of VOCs.

Continuous bleed devices are used to modulate flow, liquid level or pressure, while continuously venting gas from the controller. To decrease VOC emissions, the EPA has placed limits on the steady-state bleed rate of continuous bleed natural gas-powered pneumatic controllers. The EPA’s background technical support document states, “actuation emissions serve the device’s functional purpose … and do not include emission directly resulting from actuation.” This means bleed rate during the transient control state is not considered part of the quantified continuous bleed limit. The regulation for pneumatic equipment is divided into two sections – production and gas plant facilities.

• Production facilities: For pneumatic controllers located between the wellhead and the point at which the gas enters the transmission pipeline or custody transfer, Quad-O has set the natural gas bleed limit for individual continuous bleed pneumatic controllers at 6 scfh (standard cubic feet per hour). Controllers installed or modified after Aug. 23, 2011 were required to be in compliance by Oct. 15, 2013.

• Gas plant facilities: For pneumatic controllers located at gas processing facilities, the regulation states that pneumatic controllers cannot bleed natural gas. Therefore, such controllers must be no bleed or use compressed air to operate pneumatic equipment. Controllers installed or modified after Aug. 23, 2011 were required to be in compliance by Oct 15h, 2012.

Compliance to published bleed limits should be communicated by the pneumatic controller equipment manufacturer. The regulation also includes clarifications and exceptions around pneumatic instrumentation. Some applications that require high bleed controllers for safety function, positive actuation, or response time are excluded from the regulation.

Each affected pneumatic controller must be tagged with the month and year of installation, modification and identification that allows traceability to the records for that controller. Records of manufacturer specifications detailing compliance to the applicable bleed rate must be maintained. Records detailing justification for pneumatic controllers used in applications that are excluded from regulations must also be maintained. Annual reports detailing all of this information are required.

Storage Tanks

According to the EPA, storage vessels account for a large percentage of overall VOC emissions in onshore oil and gas production. Tanks that emit, or are expected to emit, more than 6 tons of VOC emissions per year are considered affected facilities and will need to reduce VOC emissions by 95% per Quad-O.

Determination of storage vessel emission rates can be quantified by any generally accepted model or calculation methodology. A number of emission control devices are outlined in the regulation, such as closed vent systems, enclosed combustion devices and vapor recovery units. Regulation of oil tanks extends from the well to transmission of oil to the pipeline. Regulation of natural gas tanks extends from the well to the point at which gas enters the distribution system.

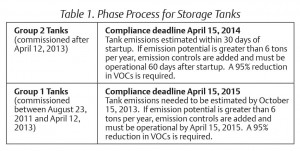

Due to the large number of affected tanks, the EPA has developed a phasing process, dependent on the date of tank construction, to allow owners and operators additional time to achieve compliance. The phasing process is defined by two separate groups as detailed in Table 1.

Newer wells associated with Group 2 tanks have elevated production rates creating greater emission potential and were regulated earlier. Group 1 is regulated later due to the inherent drop off of production over the lifetime of a well.

For wells with low production rates, an alternative storage vessel emissions limit is established in lieu of the 95% emissions reduction. Owners that can demonstrate emissions below four tons per year over the course of 12 consecutive months can remove emission control equipment and use it on a higher emitting vessel. If at any time emissions rise above the estimated four tons per year, the 95% reduction rule goes back into effect. Emission control devices selected for the tank should be tested and rated by the manufacturer to provide a 95% reduction in emissions in lieu of field emission testing.

Compressors

Quad-O addresses emissions from compressors used to move natural gas at gathering and boosting stations and processing plants up to the point at which gas enters the transmission pipeline. Compliance activities differ depending on the type of compressor.

• Centrifugal Compressors: Wet-seal centrifugal compressors must reduce VOC emissions by 95% through flaring or by routing gas captured from the oil seals back to compressor suction or a fuel system. Based on public comments received by the EPA, dry seal compressors have relatively low VOC emissions. Thus, they are not affected facilities and are exempt from Quad-O.

• Reciprocating compressors: Quad-O requires periodic replacement of rod packing to reduce emissions. One option is to replace rod packing every 26,000 operating hours, which must be monitored and documented. A second option is a documented replacement of packing every three years, which does not require monitoring and documentation of operating hours.

Additional documentation requirements include identification records of wet-seal centrifugal compressors and any non-compliance to Quad-O emission limits. For reciprocating compressors, records of cumulative hours of operation or number of months since the initial startup date or Oct. 15, 2012, dates of packing replacement and any deviations to the requirements outlined above must be retained.

Leak Detection, Repair

Quad-O imparts regulations from CFR 40, Part 60, Subpart VVa, more commonly known as an LDAR program for equipment at natural gas processing plants. The threshold for an actionable leakage on equipment, such as pumps and valves, is 500 parts per million (ppm). The EPA has published an LDAR best practice guide on its website, which may be referenced for compliance guidance. All new and existing equipment must meet this requirement.

Sweetening Units

Natural gas processing plants that use sweetening units to remove sulfur dioxide (SO2) must reduce emissions of SO2 by up to 99.9% per Quad-O, depending on the size of the unit and rate of sulfur production. Compliance to the standard is based on initial performance tests and daily reduction efficiency measurements. Records must be maintained for at least two years. Initial and annual reports with any deviations are required.

Glycol Dehydrators

While not specifically addressed under Quad-O, glycol dehydrator emission standards have been tightened under amendments to CFR National Emission Standards for Hazardous Air Pollutants (NESHAP) from oil and natural gas production facilities (Subpart HH) and from natural gas transmission and storage facilities (Subpart HHH).

The amendments cover small dehydrator equipment not previously subject to NESHAP, located at “major sources” of air hazardous pollutants (HAP). “Major sources” are defined as production or transmission/storage locations that emit more than 10 tons of a single HAP or more than 25 tons of a combination of HAP a year. Major sources are determined by the aggregate emission totals from the glycol dehydrators and storage vessels on site.

Small glycol dehydrators are defined as processing less than 85,000 m3 per day on average annually and must meet a specific limit of BTEX (benzene, toluene, ethylbenzene and xylene) emissions based on the unit’s throughput and gas composition. Formulas to determine the dehydrator’s emission limit are published in the appropriate subpart depending on the unit’s location.

Small glycol dehydrators installed prior to Aug. 23, 2011 are considered existing and must comply within three years from the effective date of the rule, Oct. 15, 2015. New dehydrators installed after Aug. 23, 2011 must comply with emission requirements upon startup.

This article serves only as a topical overview of Quad-O affected facilities, with the goal of alerting owners and operators to the need of understanding and complying with these new regulations.

Quad-O’s scope is broad, affecting the onshore oil and gas industry from production through transmission, with pending rules for compressors and pneumatic controllers located at compressor stations on the horizon. Data collection and reporting for sites is considerable. As seen in other industries, if these requirements are not correctly followed, errant or overlooked reporting can lead to enforcement consequences years down the road.

Quad-O constitutes significant air quality regulations for the onshore oil and gas industry and are now written law, and the EPA can be expected to enforce compliance and reporting in the near future. The EPA’s Natural Gas STAR program was referenced during creation and promulgation of Quad-O regulations and can be consulted as a resource. Five EPA-written white papers on methane and VOC emissions to be used as an industry reference were released in April 2014.

Summary

In review, affected facilities are wells and equipment were installed or modified on or after Aug. 23, 2011. Owners and operators who have not already initiated steps to create a Quad-O compliance program may begin by inventorying and tagging affected facilities at their sites. A compliance process should be established to help meet requirements consistently across affected sites.

Work with affected facilities and equipment manufactures to confirm compliance with regulations and their emissions claims. Determine if an in-house certifying and reporting documentation program is the correct course of compliance or if the assistance of a consulting service would be beneficial.

It is crucial for owners and operators to review these rules in detail to better understand compliance, not only for recently modified installations, but for all future installations.

Sources:

“Standards of Performance for Crude Oil and Natural Gas Production, Transmission and Distribution,” Title 40 Code of Federal Regulations, Pt. 60.OOOO. 2012.

“National Emission Standards for Hazardous Air Pollutants From Oil and Natural Gas Production Facilities,” Title 40 Code of Federal Regulations, Pt. 63.HH. 2012.

“National Emission Standards for Hazardous Air Pollutants From Natural Gas Transmission and Storage Facilities,” Title 40 Code of Federal Regulations, Pt. 63.HHH. 2012.

U.S. Environmental Protection Agency. “Overview of Final Amendments to Air Regulations for the Oil and Natural Gas Industry.” EPA.gov, 17 April 2012. Web. http://www.epa.gov/airquality/oilandgas/pdfs/20120417fs.pdf

U.S. Environmental Protection Agency. “EPA’s Air Rules for the Oil & Natural Gas Industry: Summary of Key Changes to the New Source Performance Standards.” EPA.gov. 17 April 2012. Web. http://www.epa.gov/airquality/oilandgas/pdfs/20120417changes.pdf

U.S. Environmental Protection Agency. “EPA’s Air Rules for the Oil & Natural Gas Industry: Summary of Requirements for Processes and Equipment at Natural Gas Well Sites.” EPA.gov. 17 April 2012. Web. http://www.epa.gov/airquality/oilandgas/pdfs/20120417summarywellsites.pdf

U.S. Environmental Protection Agency. “EPA’s Air Rules for the Oil & Natural Gas Industry: Summary of Requirements for Processes and Equipment at Natural Gas Gathering and Boosting Stations.” EPA.gov, 17 April 2012. Web. http://www.epa.gov/airquality/oilandgas/pdfs/20120417summaryboost.pdf

U.S. Environmental Protection Agency. “EPA’s Air Rules for the Oil & Natural Gas Industry: Summary of Requirements for Processes and Equipment at Natural Gas Processing Plants.” EPA.gov, 17 April 2012. Web. http://www.epa.gov/airquality/oilandgas/pdfs/20120417summaryprocessing.pdf

U.S. Environmental Protection Agency. “EPA’s Air Rules for the Oil & Natural Gas Industry: Summary of Requirements for Processes and Equipment at Natural Gas Compressor Stations.” EPA.gov, 17 April 2012. Web. http://www.epa.gov/airquality/oilandgas/pdfs/20120417summarycompressor.pdf

U.S. Environmental Protection Agency. “EPA’s Air Rules for the Oil & Natural Gas Industry: Summary of Requirements for Equipment Used in Oil Production.” EPA.gov, 17 April 2012. Web. http://www.epa.gov/airquality/oilandgas/pdfs/20120417summaryoil.pdf

U.S. Environmental Protection Agency. “EPA’s Air Rules for the Oil & Natural Gas Industry: Information for States on Attainment Planning, Permitting and Compliance.” EPA.gov, 19 April 2012. Web. http://www.epa.gov/airquality/oilandgas/pdfs/20120419infoStates.pdf

U.S. Environmental Protection Agency. “Oil and Natural Gas Sector: Standards of Performance for Crude Oil and Natural Gas Production, Transmission, and Distribution: Background Technical Support Document for Proposed Standards.” EPA.gov, April 2012. Web. http://www.epa.gov/airquality/oilandgas/pdfs/20120418tsd.pdf

Airhart, Jarrett and Tom Muscenti, PE. Oil and Gas Industry Faces Significant New Air Quality Requirements. Trinityconsultants.com. Trinity Consultants, 17 July 2012. Web. 27 Aug. 2013. http://www.trinityconsultants.com/Templates/TrinityConsultants/News/Article.aspx?id=4311

Comments