February 2014, Vol. 241 No. 2

Features

Fast-Track Mapping: New Solution For Tracing Utility Assets

Soon, nearly every shipment of pipe and fittings delivered to natural gas operators in the United States will include barcodes that store a wealth of information about each item. These 16-digit alphanumeric codes will serve as the basis of a ASTM standard (F2897-11a) and will help utility operators address new distribution integrity management (DIMP) regulatory requirements.

Developed with sponsorship from Operations Technology Development (OTD), a partnership of natural gas distribution companies, the barcodes are already appearing on natural gas components manufactured by Dura-Line/PolyPipe, RW Lyall, and many other manufacturers.

Embedded in the code is information about the manufacturer, lot number, production date, material, component type and size of each item. In the years ahead, these barcodes will provide valuable traceability information that utility operators will be able to use to track each asset throughout its lifecycle.

New Lifecycle Tracking Technology

Gas Technology Institute (GTI), a research, development, and training organization, recently took the barcode identifier a step further with the development of a technology solution that leverages barcode scanning and geographic information systems (GIS) technology.

The result: 3-GIS Mobile 2.1 with Android, a mobile-mapping technology that promises to change the way utilities map new pipeline installations. Now available commercially, the application leverages mobile GIS technology to decrypt the barcode on pipes and fittings as they are installed in the field.

From the decrypted barcode, the software automatically creates a new feature – such as “pipe,” “valve,” “tee” – in the GIS database, then populates the attribute fields with other information about the asset contained in the barcode, which could include “material” and “lot number.” By using a simple scan to populate the features directly into a GIS environment, the need for any back-office conversion is eliminated.

After the assets are mapped, the data is sent to a cloud environment or a server behind a company firewall, where it can be viewed or pulled back into the corporate GIS database.

“Now, in real time, the utility operator has a GIS record for every asset installed underground, which eliminates mapping backlogs,” said Alicia Farag, program manager at GTI. “In the case of a manufacturer recall, the operator can query specific components and identify their exact location for quick replacement.”

Repair, Replacement Projects

The new application will enable natural gas operators to collect critical data as they move forward with repair and replacement projects. With the new technology, field crews will be able to map the location of pipes as they are installed and to create complete records.

The accelerated main replacement program (AMRP) is a major replacement project that is already underway at Peoples Gas, a natural gas delivery company serving about 829,000 customers in Chicago. With the project, Peoples Gas plans to replace all of its remaining cast- and ductile-iron natural gas mains with polyethylene pipes. The utility participated in a pilot demonstration of the new mobile GIS application recently, because it wants a better method for tracing material.

“We know that barcode scanning in the field provides timelier as-built information for our back-office GIS staff and that having a lot of this information pre-populated out in the field streamlines the process,” said Richard Mosar, supervisor of GIS Services at Peoples Gas. “By using GPS technology, we can obtain more accurate spatial location information about our assets as well.”

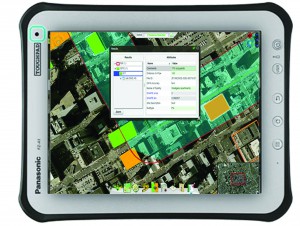

According to Farag, the ultimate goal is to provide technology that will allow the industry to transition away from paper records to geospatially enabled data collection – and to make it easy for “the guys in the field with tablet computers” to access familiar user interfaces. (Figure 1.)

Asset Data In Corporate GIS

National Grid, an electricity and gas company serving 3.3 million electric and 3.4 million gas customers in Massachusetts, New York and Rhode Island, is also looking to the new mobile GIS application to aid its ongoing effort to convert information from a diverse set of legacy mapping systems, acquired predecessor organizations, into a single GIS system.

National Grid is participating in a pilot project to determine the viability of the mobile GIS application for tracking and traceability of future material and pipe installations.

“We will be evaluating the use of barcode scanners, GPS locators, and tablet computers for data capture at the site of new gas service installations in each of the four regions in which we operate,” said Parashar Sheth, manager of Gas Materials and Standards for National Grid.

As new installations are completed, National Grid will gain detailed manufacturer data in order to react appropriately to situations as they arise.

“Knowing who manufactured the pipes and fittings we bury in the ground, the lot numbers, and other details would help us going forward if at any time we have a systemic problem or a manufacturer sends us a recall notice,” Sheth said.

New Workflow

Using the new mobile GIS mapping software will enable natural gas operations to reach new levels of productivity, efficiency and accuracy when mapping the locations of utility assets. In the past, field crews took manual measurements from movable landmarks and created paper records known as “as-builts.”

“Today, even though many utility operators have made investments in GPS technology to improve the mapping of new installations, GPS hasn’t replaced paper maps and records, because of the cost and complexity of the technology,” Farag said.

Crews, armed with these capabilities, will be able to create GIS features in the field, so there is no need to convert GPS data into GIS features in the office. The software makes it possible to automatically populate feature attribute information from barcodes, so there is no need for the user to select or enter values (Figure 2).

The new process provides significant time and productivity savings – it takes less than a minute and provides sub-foot accurate GPS in real time so data is available in the back office immediately.

Changing Status Quo

There is no doubt that the application of new mobile GIS capabilities, barcode scanning, cloud computing, and in-depth data sets – combined with the ability to access it all on a wide range of consumer-grade Android devices – are changing the way today’s natural gas operations work. More than just mapping the location of underground assets, mobile GIS technology can now enable seamless field-to-office workflow solutions.

“Now, by collecting field data on mobile devices – for surveys, inspections, repairs and new installations – there’s no need for manual data transfer and processing, and electronic data can replace paper forms and records, optimizing the whole data management process,” Farag said.

Comments