July 2013, Vol. 240 No. 7

Features

The Many Phases Of Multiphase Flow Meters

The history of oil well drilling goes back to 1859 to a farm in northwestern Pennsylvania. The farm was located in Titusville, near Erie. Edwin Drake and George Bissell cooperated to drill the world’s first oil well. While Drake is usually the one credited with drilling the first well, he did not have a good head for business and spent much of his life in poverty. Bissell, by contrast, became quite wealthy and outlived Drake by four years.

Drake’s main contribution to the project was to introduce a pipe lining in the drill hole. He and Bissell cooperated to form the Seneca Oil Company with Drake as president. While drilling, they struck oil 69 feet below the ground. Bissell became wealthy by buying, selling and leasing land in the Titusville area.

The discovery of oil touched off an international search for black gold that continues to this day. In the past 150-plus years, many fortunes have been made and lost in the pursuit of oil. One of the most famous of these is John D. Rockefeller, who formed Standard Oil Company. Standard Oil was the predecessor of Esso Corporation, which became Exxon, and is now ExxonMobil. ExxonMobil is among the largest corporations in the world. The need for oil has spawned more than one war, including the Gulf War in 1990. It also played a role in the Iraq War, initiated by the United States in March 2003.

Oil has become such an integral part of modern society that it is difficult to imagine life without it. In the past 10 years, however, scientists and oil analysts have come to realize that the world’s supply of oil is not unlimited, and they have initiated a search for alternatives that can eventually serve as a substitute. Chief among the alternatives is natural gas, which is far more plentiful than oil and is likely to outlast oil by many years. Other possibilities include alternative fuels, such as solar power, wind power, biogas, biomass and fuel cells. The problem with these fuels is they are only in the early stages of development, therefore, still quite expensive.

Today oil analysts argue whether we have yet reached “peak oil.” The idea behind peak oil is that at some point, the world will have produced the maximum amount of oil it can, measured generally in barrels per day. After that, the world’s total production will begin to decline, and we will seriously be looking at the end of plentiful oil supplies. While total world oil supplies are continuing to increase slowly, it is inevitable at some point they will begin to decline. This is almost certain to happen in the next 10-20 years.

North Sea Oil Fields

The North Sea oil fields played a critical role in the development of multiphase flow meters. The first commercial oil field in the North Sea dates back to 1969 when the Arbroath oil field was discovered. In 1970, the Forties field confirmed the exploration potential of the waters near Scotland. Following this, a substantial number of discoveries were made in the first half of the 1970s. Oil production grew from very low levels in 1975 to 2.5 MMbopd in 1985 in the North Sea fields.

Oil prices during this time were extremely volatile. In 1972, the price was in the range of $2.50 per barrel. Early in 1981, it rose to $40 per barrel. Then in the summer of 1986, oil prices dropped below $10 per barrel. Oil prices have remained volatile to this day, as the price of West Texas Intermediate (WTI) runs between $90-100 per barrel. Brent crude, which is associated with the North Sea, is in excess of $100 per barrel.

Enter Multiphase Flow Meters

Multiphase flow meters were born out of research conducted in Norway and Scotland in areas near the North Sea. Much of the initial research was done by the Christian Michelsen Institute (CMI) in Bergen, Norway in the early 1980s after oil production in the North Sea wells began to decline. The purpose of creating multiphase flow meters was to find a way to analyze the increasing amounts of water and natural gas that were becoming a greater part of the fluid from some of the North Sea wells.

It is typical for oil wells to have a mixture of oil, natural gas and water. Prior to the invention of multiphase flow meters, the only way to determine this mixture was to physically separate the fluids and measure each one individually. Test separators performed this function. With the advent of multiphase meters, it was possible to measure the flow at the wellhead and reduce or eliminate the need for separate test separators. This can be especially important on oil platforms at sea where space is at a premium.

How They Work

Because they measure the relative proportion of different types of fluids, multiphase meters combine several measurements. These measurements include temperature, pressure and differential pressure (DP). Most multiphase meters have a nuclear source that helps determine fluid properties. The most common type of nuclear source is gamma rays. Some companies use low-energy gamma rays, others use high-energy gamma rays. Some use a combination of the two.

The gamma ray technology is used to determine the relative percentage of oil, gas and water in a fluid. Multiphase meters use this information to measure the flowrate of the different fluid types. The most common method of measuring flowrate is with a differential pressure measurement, using a Venturi tube. Density is determined with a combination of differential pressure, pressure and temperature. The DP flowrate is combined with the value of the percentage of each fluid to determine the flowrate of each fluid.

Benefits of Multiphase Meters

Multiphase meters provide valuable data about the composition of the fluid coming out of the well. But they also provide important information about the well itself. For example, an increase in the percentage of water coming out of a well can indicate a declining well. The same holds true if the percentage of oil to gas is being reduced. Multiphase meters give a faster response time than test separators because they give the data in real time.

Multiphase meters are also useful for allocation metering where the fluids from different wells need to be combined and sent to a processing center. With test separators, the fluid from each well has to be physically separated before being sent on for processing. Using multiphase meters, this step is unnecessary. The flowrates and composition of the fluid from each well can be determined by the multiphase meter without using a test separator.

Issue Of Cost For Multiphase Meters

There is a wide range in the costs of multiphase meters, depending on application. Some are available for land-based wells at less than $100,000. Others that are designed for subsea applications can cost as much as $750,000. Due to the price, multiphase meters are most often placed on high-producing wells that yield high-value fluids.

Back To Norway

The research done by the Christian Michelsen Institute (CMI) in Norway had a long-term impact on the future of multiphase flowmeters. CMI teamed up in its research with the National Engineering Laboratories (NEL) in Scotland. From 1982-85 CMI did the research necessary to found Fluenta, a company that manufactures ultrasonic flare gas meters. Today, there are a number of multiphase meter companies in Norway, including Framo Engineering (Bergen), Roxar (Stavenger), MultiPhase Meter (MPM) (Stavenger) and Abbon (Rud). Bergen is the home of CMR Instrumentation. Some other companies in this market include Agar, Cameron and Weatherford.

A Look Ahead

The multiphase flow meter market is a dynamic and very exciting one. A great deal of research is being done, including some by end-users. It will no doubt take some time, but one or more companies are likely to come up with some very good products that outperform anything currently on the market. This market is at an earlier stage of development than the Coriolis and ultrasonic markets, but in some ways the stakes are higher. The drive for more oil and natural gas will only intensify over the next five years, and working multiphase meters are one way to make things more efficient and productive. This market will continue to flourish.

Author:

Jesse Yoder, Ph.D., is an internationally recognized expert in metering research and a contributing editor to Pipeline & Gas Journal. He leads Flow Research, Inc., Wakefield, MA. He can be reached at jesse@flowresearch.com

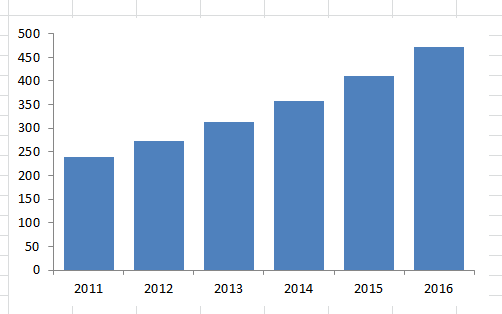

Source: Module E: The World Market for Multiphase Flowmeters, publlished by Flow Research, Inc.

Comments