June 2013, Vol. 240, No. 6

Features

Shale Boom Finds Ready Partner With Stupp

For Johann Stupp and five succeeding generations of the Stupp family, America has certainly been a land of opportunity. Still, it’s unlikely that 157 years ago, Johann could ever have imagined that a company bearing his name would be known worldwide as an industrial leader providing essential materials for the construction of pipelines, bridges, sports facilities and even high-rise buildings.

Stupp Corporation marked its 60th anniversary last year. It maintains two pipe mills outside of Baton Rouge, LA which employ nearly 500 people and produced about 450,000 pipe tons in 2012. That is about the triple the amount of business the company reported in 2005.

It is part of Stupp Bros. Inc., a sixth-generation family owned business with headquarters in St. Louis, MO. That takes us back to Johann. According to family history, Johann was a German immigrant and master locksmith who founded J. Stupp and Bros., Blacksmiths in St. Louis in 1856. One of his early jobs was helping build a fleet of ironclad gunboats for the Union Army.

Johann’s business prospered until 1875 when he lost his business to an unscrupulous lender, the story goes. Somehow he was able to persuade a teamster who hauled iron for him to act as proprietor of a new “Ornamental Iron and Zinc Works” business almost next door to his old location. With the aid of his three sons Johann rebuilt his business and in 1882 the name was changed to Stupp Bros. Iron Works.

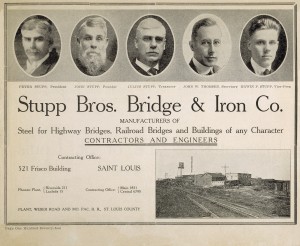

By the 1890s what was now Stupp Bros. Bridge and Iron Co. won a charter allowing them to build and repair all kinds of iron and steel structural work in Missouri. In 1915, Johann died at age 88, but he left his business in the capable hands of his sons, who continued the tradition of passing the business to the next generation.

Enduring both prosperous and lean times, the company has evolved into a major player that culminated in the opening of a new $80 million helical submerged arc weld pipe mill in 2009. The manufacturing process presents the steel coil to the welder at an angle, producing seams on a spiral as opposed to along a straight line and can reach diameters up to 60 inches, the company said.

Another important milestone in company history occurred in 1993 when Stupp partnered with The Bayou Companies of New Iberia, LA and formed Bayou Coating, a fusion bonded epoxy coating plant on Stupp’s campus, making Stupp one of the market’s first integrated providers of coated pipe. Today, the Baton Rouge coating mill is among the most productive FBE, ARO and internal coating plants in North America and Stupp is continuing to invest by expanding the plant’s upper size limit from 42” to 48” to accommodate some of the larger diameter pipeline projects on the horizon.

In this interview, John P. Stupp, Jr. president and director, Stupp Bros. Inc., discusses his company’s legacy and its business strategy, all with an eye to the future. A graduate of Lehigh University with a BS degree in Business and Economics, he served for 20 years in the U.S, Army Reserve, retiring as a colonel. A resident of his native St. Louis, Stupp is an active member of the community , serving on the boards of hospitals, libraries, children’s homes, and business councils.

P&GJ: What were your interests as you were growing up and when did you decide to enter the family business?

Stupp: Like most kids I enjoyed sports of all types and played baseball, basketball, football, golf and tennis. I was also a competitive skeet shooter with my dad. I don’t think I had a choice not to be in the family business! I started working in the summers as a 12-year-old and was on my way from then on.

P&GJ: How has Stupp Bros. managed to keep the company within the family for so many years, and what other members of the family are involved with the business?

Stupp: Stupp has been family-owned and managed since its founding in 1856. Our principles evolved over time, but the main thought has always been to put the business first and that has allowed us to survive through the serious downturns. Besides me, we have three other family members working for the company.

My uncle Robert is the chairman of the board of Stupp Bros., Inc., and his son (my cousin) Philip is executive vice president and secretary of Stupp Bros., Inc., and president of the Fabrication Segment. My nephew Chip is the first-sixth generation family member to join the company. He’s the director of Continuous Improvement for the pipe division.

P&GJ: What are the challenges involved in keeping a business family-owned? Certainly you and others have had offers from prospective buyers.

Stupp: We have worked hard to create a balance between working and non-working family members, and we are all challenged and motivated to advance the legacy that so many other generations built. As a private company, our access to the capital markets can be more challenging, but we have always wanted to keep the company in the family.

P&GJ: How has the company evolved and grown through the years – when did it get involved in pipeline services and how much of your business involves pipelines?

Stupp: The business was founded in St. Louis and our capabilities grew with the city as we provided more and more iron and steel products to the region. For our first century, we progressed from farm implements to jail cells to fencing, then steel bridges and structural steel for sugar mills, paper mills and steel mills. Starting with the Civil War, we have always diverted our production capacity to make defense products our priority when America was at war.

That’s actually what led us to the pipe business in 1952 when we formed a joint venture to make petroleum transmission pipe to support amphibious landings in Korea. Today our line pipe business is the biggest part of what we do.

P&GJ: What are considered the most important events in the company’s history?

Stupp: Taking the leap to expand our business in the 1880s to fabricate bridges for the first Federal Highway Program was a big turning point. We made another strategic move in the 1950s when we entered the pipe business which exposed us to important new markets and expanded our geographic reach.

P&GJ: During cyclical downturns, how did you manage to keep the business afloat?

Stupp: Recovering from failure during the Panic of 1873 and barely surviving the Great Depression taught us the significance of financial strength in the business in order to weather downturns.

P&GJ: How would you describe your leadership style, and have you had to revise it during your career?

Stupp: Besides my formal education at Lehigh University, I learned management as an Army officer. During my first 15 years in the family business, I continued to learn from my father and other managers in our company. As the company has grown over the last 20 years, I have learned the importance of letting others have and exercise responsibility.

P&GJ: In January, Stupp Bros. announced it was going to partner with APCI. What were the reasons behind this and how does it benefit both companies? Is this a new business center for Stupp Bros.?

Stupp: Even though steel is viewed as a mature industry, Stupp is a big believer in utilizing cutting-edge technologies to enhance and improve existing processes and produce higher quality products and services for our customers. Early last year, we tasked our director of Technology Applications with researching next-generation welding methodologies, and he came across APCI – an Indiana-based R&D firm with a patented technology for linear friction welding.

Stupp took an operating interest in APCI to help them commercialize this solid-state bonding method which has the unique ability to join dissimilar metals and shapes. We see applications for this game-changing technology not only in our traditional markets like construction and energy but also in transportation and aerospace.

P&GJ: Are you eyeing other areas for future growth, either geographically or as business profit centers?

Stupp: In the near-term, we are focusing our effort on two growth areas. We have produced pipe for quite a few international projects over the years. Since Baton Rouge is a deepwater port and has great rail service into Mexico, we can efficiently supply coated line pipe to Central and South America as well as West Africa.

We recently won a large transmission project for a major Mexican operator – the first international pipeline project for our two-step spiral mill. We have our eyes on a few others as well. Secondly, we’ve accumulated an immense amount of logistics expertise over the past 60 years, and we’ve just made integrated services like transportation, offloading, and storage a part of our everyday service offering. We have found that this is a great benefit for small to mid-size operators who want to de-risk their projects and simplify their supply chain.

P&GJ: You spent 20 years in the U.S. Army Reserves. Do you have any particular memories that stand out from your service time, and do you feel that opportunity has helped you lead Stupp Bros.?

Stupp: I benefited greatly from active and reserve military service and commanding a unit was a highlight and a great preparation for business leadership.

P&GJ: What technologies and innovations have helped make Stupp Corp. unique in its field?

Stupp: Something that has set Stupp apart from our competitors is our dedication to the midstream industry. The driving force behind our innovations is to provide value to our customers by saving them time and money beyond the mill. For example, we pioneered custom grades and wall thicknesses to meet operators’ intended pipeline pressures so they could save money by using less steel.

We engineered the production and transportation of 80-foot lengths to help our customers dramatically reduce their logistics and installation costs. Other innovations like our state-of-the-art digital x-ray system eliminates film and can examine up to 16-inch of pipe end — twice API’s requirement — which reduces the chance of defect in the field. We also constantly review new welding and non-destructive testing technologies to make our products better.

P&GJ: What are some of the more interesting and/or challenging energy projects Stupp Corp. has worked on?

Stupp: One story of which we’re particularly proud is a 20-inch project we supplied for a 200-mile gas line in the mountainous Uinta Basin. After constructed ended, we got a call from the customer. They said they ran a cleaning pig through the line, and when it arrived at the receiving station, they found that it was severely damaged.

Their analysis determined that part of the line had been smashed by earth movement, and they were calling to let us know that they were impressed by the integrity of our pipe because no leak resulted from the damage. They actually gave us pieces of the section they cut out, and we have them mounted in our offices to remind us of the importance of our product’s quality.

P&GJ: How has the shale revolution affected your business strategy?

Stupp: America is very fortunate to have discovered and perfected the ability to extract gas, oil and NGLs from shale. We have enjoyed operating at company-record production levels to support our customers who are helping make America much more energy-independent.

P&GJ: What are the biggest changes you’ve seen in the pipeline industry since you began your career and what are the biggest challenges facing pipe mill operators such as Stupp Corp.?

Stupp: The deregulation of the natural gas industry and the shale boom are the biggest changes we have seen. The greatest challenges we face are the weakness in the rest of the world’s economy and the flood of unfairly traded imports from countries that have overbuilt pipe and steel capacity.

P&GJ: When you retire, what would you and your family like to do?

Stupp: I am looking forward to bringing on the sixth generation of family leaders and watching them grow the business. We have some sharp young people coming along so maybe they will allow me to play some more golf and for my wife and me to do some traveling.

P&GJ: Is there any particular individual whom you would like to credit for having an especially strong influence on your life and your career?

Stupp: There are really too many to list for fear of leaving someone out, but obviously my parents, Jack and Helen Stupp, are at the top of the list.

Comments