November 2011, Vol. 238 No. 11

TechNotes

Screw Anchors Go To Work Stabilizing Pipelines

For the past 30 years, AnchorPipe has designed and installed over 100,000 screw anchors and ScrewPiles to permanently stabilize new and existing pipelines. In the past two years, the firm says it has seen a variety of applications for screw anchors and ScrewPiles from buoyancy control in flood prone areas, lowering pipelines to their original elevation, supporting pipelines over onshore creeks and offshore risers, and in storm current (lateral load) protection.

California. In summer 2010, AnchorPipe installed 36 ScrewPiles, each holding 100 Kips, on Chevron’s 63-inch HDPE pipeline offshore from El Segundo, CA. The company used one of its anchoring rigs to stabilize the anchor installation motor in the strong current as well as provide down pressure. Curtin Maritime provided a four-point anchor barge with crane and divers to support AnchorPipe’s anchoring rig. Each 100-Kip anchor set was installed in about two hours including vessel and rig moves. (Pictured at head of article.)

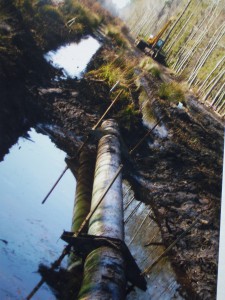

Georgia. Shortly after installation, a 24-inch pipeline began floating near the Ogeechee River around Richmond Hill, GA. An apparent lack of concrete coating allowed for this buried pipeline to sand jack to the surface. Due to the limited access, a marsh buggy was used to support AnchorPipe’s anchor drive motor to install the ScrewPiles.

The ScrewPiles were used to pull down a floating 24-inch Southern Natural Gas pipeline. These Anchor sets also had a cross member added to provide support.

Gulf of Mexico. During May 2010, CalDive provided a work vessel with crane and divers to support AnchorPipe’s installation of five hold-down anchor sets on a 20-inch pipeline for Panhandle Energy. The pipeline had moved 1,000 feet from its original location in Grand Isle 94 during Hurricane Katrina.

The job called for the screw anchor sets to permanently stabilize the pipeline in its new location. The water depth was 200 feet. Once the vessel was on location, the hold-down screw anchors were each installed in an hour or less.

Navajo Nation. In 2009, AnchorPipe installed four ScrewPile supports for creek crossings in the New Mexico desert. This Navajo Nation 16-inch pipeline was 15 feet off the creek bed in some areas. Each ScrewPile support was designed to hold 50 Kips. A long-reach excavator was used to support the company’s anchor drive motor.

Oregon. In 2010-11, Rockford Construction laid a 42-inch pipeline for El Paso’s Ruby Pipeline Project in Oregon. Several miles of this pipeline crossed an old lakebed which is prone to flooding. Gravity anchors such as set-on weights and concrete coating – while more than twice the cost of screw anchors – were not practical due to issues with access to the right-of-way. These 60-Kips anchor sets were installed on most occasions in less than 15 minutes.

Undisclosed Site. During summer 2011 the company provided multi-helix high-torque anchors to permanently stabilize some bulkheads and retaining walls. The company says these anchors can be installed utilizing an excavator with AnchorPipe’s anchor drive motor attached in place of the bucket. Utilizing an excavator, the anchors can be installed at an angle and with down pressure. In most cases these anchors are required to hold 25-50 Kips.

Comments