October 2011, Vol. 238 No. 10

TechNotes

Big Engines Excel With Puradyn Oil Filter System

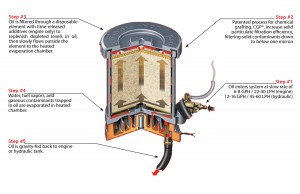

Puradyn Filter Technologies says its bypass oil filtration system keeps engine and hydraulic oil continuously clean by trapping solid contaminants down to below one micron and removing liquid and gaseous waste.

The company says a single TF-240 bypass oil filter will micro-filter an oil sump capacity of 75 gallons.

According to Puradyn, a single puraDYN® TF-240 bypass oil filter will micro-filter an oil sump capacity of 75 gallons and is designed to be used in multiples, where engines can hold up to 400 gallons of oil.

The company says the system allows oil to maintain proper viscosity and chemical balance through additive replenishment incorporated into the replacement filter element. This process is said to keep the engine running cleanly and efficiently.

Cutaway view of the bypass oil filter system with labels.

Since the engine can be kept running even while changing the filter, the company says experience indicates a large decrease in downtime. This is said to make it ideal for use in remote locations where engines must operate 24/7.

Waukesha And CAT Engines

The gas pipeline industry is one industry where it is crucial to keep engines and compressors running at all times. Puradyn has worked for the past five years with one prominent gas pipeline operator that has a fleet of 61 natural gas compressors, made up of Waukesha and CAT engines. The operating company – a leader in natural gas gathering and treatment with a strong emphasis on protecting human health and the environment – specifically cites engine cleanliness from operating with oil kept constantly clean by the bypass oil filtration system as the determining factor in extending its engine overhaul intervals.

Since installing the system, the operating company changes oil, the puraDYN® replacement filter, and the engine filter every four months of 24/7 operations (or 2,600+ hours). They have had no maintenance issues. In fact, due to the cleanliness of the engines and the efficient water removal through the use of Puradyn’s micro-fine filtration technology, they have been able to extend engine overhauls by 10,000+ hours.

Puradyn was selected as the manufacturer used by the Department of Energy for the duration of a three-year evaluation to research and analyze the performance, benefits and cost analysis of bypass oil filtration technology. In government tests, the filtration systems reduced new oil purchases, oil waste and disposal volumes by nearly 90%.

Comments