September 2010 Vol. 237 No. 9

Features

Best-Practice Effort Seeks To Foster Reliability, Integrity, Safety, Confidence

As the nation’s interstate natural gas pipeline system has grown, so too has the need for continuous improvement by industry, notably in the areas of pipe manufacturing, quality control, and pipeline construction and operation.

In the 2007-2009 period, the amount of new pipeline miles in the U.S. more than doubled from levels seen earlier in the decade, increasing to approximately 8,000 miles of new pipeline during the latest period. With this rapid growth, the Pipeline and Hazardous Materials Safety Administration (PHMSA) of the U.S. Department of Transportation’s Office of Pipeline Safety began conducting more inspections and observed issues in need of review by pipe manufacturers, construction companies, and pipeline operators. This increased activity, as well as issues seen by the agency on newly installed pipelines, led to a need for thorough reviews of both low- and variable-strength yield pipe, pipe chemical composition, bevels on the end of pipe, welding, pipe coating, segmenting of hot bends and offset weldability, and construction personnel knowledge issues.

The need for such a review was highlighted at a PHMSA public meeting and subsequent industry workshops in 2009. PHMSA also issued an Advisory Bulletin in May 2009 regarding potential low- and variable-yield and tensile strength and chemical composition properties in high-strength line pipe. PHMSA pinpointed the issues that needed to be addressed, and industry embraced the challenge of identifying the underlying causes and corrective measures.

Continuing a proactive posture, and following 2008-2009 workshops on pipeline welding, pipe quality assurance/control, and construction, members of the Interstate Natural Gas Association of America (INGAA), through the INGAA Foundation, undertook a comprehensive study, unprecedented since enactment of the Pipeline Safety Act of 2002, which mandated new standards for pipeline integrity, inspection, and maintenance. The study’s objectives centered on obtaining a better understanding of the issues, seeking ways to improve standards, and enhancing pipeline system and facility reliability, integrity, safety, and confidence during the entire life cycle of pipe: procurement, installation and operation. Following issuance of the PHMSA Advisory Bulletin, the INGAA Foundation held a Pipe Quality Summit and a separate Construction Quality Summit in June and October 2009, respectively.

Those efforts led to the development of a Pipe Quality Action Plan and Pipeline Construction and Solutions Action Plans to address the concerns of the regulator, bring about positive change, enhance awareness of the issues, instill confidence, and help underscore industry’s stewardship not only for the regulator but for the general public.

In a very short period of time, given the tasks and work required in 2009 and so far in 2010, industry has made and continues to make good progress. Industry has stepped up to the challenge: the efforts mandated by PHMSA’s Advisory Bulletin have been strongly supported by individual stakeholders in the INGAA Foundation. As we continue our work, industry’s efforts are being observed by stakeholders other than our regulator. More work is ahead as we collectively continue to pursue best practices to enhance system reliability, integrity, safety and confidence. This report outlines industry’s achievements through the INGAA Foundation and what remains to be achieved.

The PHMSA Challenge

In the last several years, INGAA and the pipeline industry have made strides in enhancing the effectiveness of practices in the areas of developing operating procedures on parallel construction, testing of low-yield pipe, mitigating welding issues, and conducting above ground-surveys that detected coating damage. But PHMA’s Advisory Bulletin called for an even greater commitment by the industry to evaluate high-strength steels, including Grade X-70 and higher, to identify the potential for low- and variable-yield strength pipe, including ultimate tensile strength and chemical properties of recently installed pipe.

According to the regulator, there was a need to investigate raw material manufacturing procedure specifications and test results for steel, slab and coil, pipe specifications and review technical documentation, covering pipe production test results, including hydrostatic test results. In addition, PHMSA believes that, based on knowledge and findings, industry through its trade associations should consider using deformation tools to detect expansion of pipe resulting from low-yield strength.

The challenges posed by PHMSA were multi-faceted, and provided an overarching approach for a comprehensive new effort by industry:

1. How can industry and PHMSA credibly define the precise nature and extent of problems identified during the recent new pipeline construction projects?

2. Which underlying standards or regulations need to be examined or changed to help improve pipeline fabrication and construction quality control?

3. What other ideas to improve overall fabrication and construction quality control does the industry believe warrant additional attention?

4. Does your association and membership see value in developing a more comprehensive quality management system standard to make these improvements? If so, which system elements would you see as needed?

5. At a minimum, which testing and quality control requirements do you (industry) believe need to be incorporated into all new pipeline construction projects to ensure their fitness for purpose prior to commissioning?

6. Lastly, though process and technology improvements may be needed, how can we (or the industry) ensure that workers employed in these fast-paced and challenging construction projects are fully trained and qualified to carry out their duties competently?

Action Plans: Pipe Quality and Construction

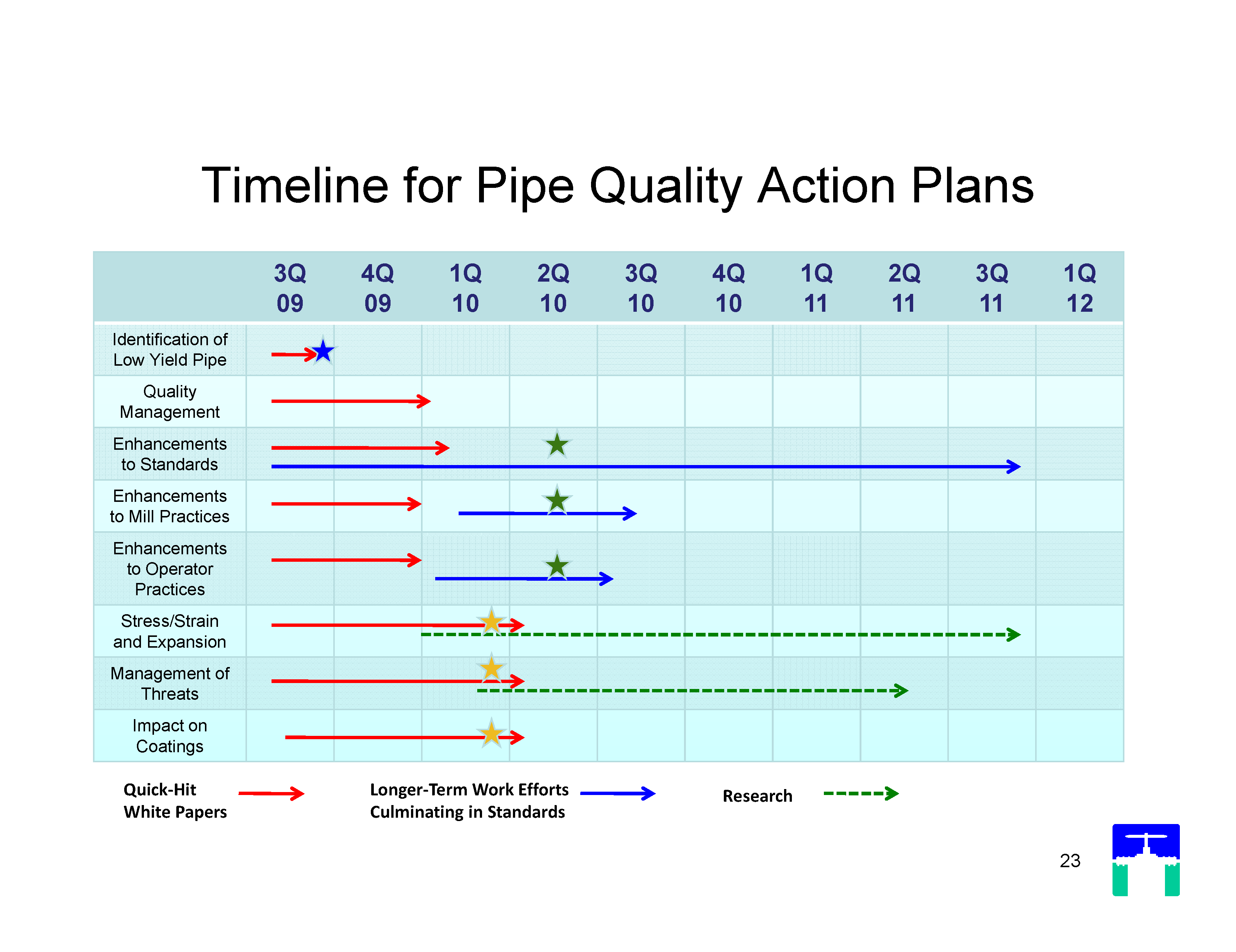

The Pipe Quality Action Plan included eight elements. These are:

Pipe Quality Action Plan:

1. Identification of Low- and Variable-Yield Strength in High-Strength, Low-Alloy Line Pipe Steel

2. Line Pipe Quality Management

3. Evaluation of Enhancements to American Petroleum Institute (API) Pipe Standards

4. Evaluation of Enhancements to Operator Specifications and Practices

5. Evaluation of Enhancements to Pipe Manufacturer Specifications and Practices

6. Understanding Steel Stress Strain Behavior and Pipe Expansion

7. Development of Methods to Understand Implications of Expansions on Stress and Strain and Implications to Each Threat in ASME B31.8S

8. Evaluate Implications of Expansions On Pipe Coatings

The Pipeline Construction Quality Issues and Solutions Action Plans included six elements. They are:

Pipeline Construction: Quality Issues and Solutions Action Plans

1. Best Practices on Implementing API 1104

Appendix A

2. Resolution of API 5L and 1104 Non-Destructive Evaluation Issues

3. Best Practices for Field Applied Coating

4. Quality Management System for Pipeline Construction

5. Training Guidance (simplified “KISS” approach) for Construction Workforce & Inspectors – Welding and Coating

6. Develop Technical Guidance for Segmenting Hot Bends and Offset Weldability

A summary of the work efforts and progress is described in the accompanying sidebar articles.

Working Groups – Pipe Quality

Group 1 – Identification of Low- and Variable-Yield Strength in High-Strength, Low-Allow Line Pipe Steel

Scope: Develop a uniform process for responding to the PHMSA Advisory Bulletin, 2009-0148.

Action Plan:

• Industry representatives will meet to develop uniform approach(es) responding to advisory.

• Tailor approach to design factor.

• Other factors, such as history with source materials.

• Will share and adjust approaches developed through interaction with PHMSA.

• Recommend considering “expected variability” in lieu of “no variability in pipe properties” in applying advisory with operators.

Status: Complete. A PHMSA-supported “White Paper” was developed and distributed in September 2009.

Group 2 – Line Pipe Quality Management

Scope: Develop a comprehensive quality management system for line pipe, building upon API 5L, Annex B

Action Plan:

• Bring issues to API Subcommittee 20 on Supply Chain Management.

• Approach SC 20 to further develop Annex B of API 5L, 44th Edition.

• Life Cycle JIP to develop white paper providing critical technical elements and background.

• INGAA and API Issue (Pipeline Operators) Policy Statement that encourages use of Annex B on projects to be operated under 0.8 design factor.

• Encourage API Monogram Program to consider audits of steel suppliers.

Status: Continuing.

After consultation, API Subcommittee 20 on Supply Chain Management was not the appropriate venue for codifying quality management systems. Solution: Ensure that steelmakers, steel processors, and pipe manufacturers use quality management systems and integrate into work of Groups 4 and 5.

The role of Group 2 was modified to provide oversight by Pipe Quality Leadership Team.

API Monogram Program announced a website (www.api.org/Newsroom/new-quality-website.cfm) enhancing anonymous reporting to monitor performance of manufacturers. The link for reporting non-conforming materials is: www.api.org/ncr.

Group 3 – Evaluation of Enhancements to API 5L

Scope: Evaluate enhancements to API 5L reflecting on changes in new edition, 44th edition, with emphasis on traceability, testing and retest provisions.

Action Plan:

• Bring issues to API Line Pipe Committee.

• Initial discussion occurred in June 2009 meeting.

• Review traceability, testing and retest provisions and verification of non-conformance practices

• Encourage involvement of PHMSA personnel in Line Pipe Committee.

• Propose that tensile test results should approximate a predicted elastic modulus; atypical values should require retest.

Status: Continuing.

Revisions to API 5L drafted in work group; balloted in 1Q 2010, now undergoing review with intent of issuing revisions by year-end 2010.

• Designate hot rolling as a process requiring validation considering tensile variability.

• Clarify testing and retesting protocols for tensile testing.

• Expand Manufacturing Procedure Specifications (MPS) and Inspection and Test Plan (ITP) requirements including protocols for non-conforming product and traceability.

Group 4 – Evaluation of Enhancements to Operator Specifications and Practices

Scope: Review processes for incorporating pipe specification provisions into pipe manufacturing processes and recommend leading practices and enhancements which operators can incorporate.

Action Plan:

• Strengthen API 5L, Annex B to incorporate process for integrating operator pipe spec provisions into MPSs and ITPs, for steel producers, steel suppliers and pipe manufacturers.

• Conduct Workshop on Best Practices for Operator QMS, including essential pre-production activities.

• Life Cycle JIP White Paper to propose process for API Line Pipe Committee to consider.

• Evaluate enhancements to traceability, testing, retesting and verification of non-conformance practices in operator specs.

Status: Continuing.

Best Practices were shared at the INGAA Foundation Pipe Quality Summit in June 2009; a

workshop on Procurement and Inspection Best Practices was held in June 2010.

• White Paper on Procurement and Inspection Best Practices is being drafted.

• Working with API and manufacturers to facilitate implementation and consistent application.

Group 5 – Evaluation of Enhancements to Pipe Manufacturer Specifications and Practices

Scope: Review processes for incorporating pipe spec provisions into pipe manufacturing processes and recommend leading practices and enhancements that manufacturers can incorporate.

Action Plan:

• Strengthen API 5L, Annex B to incorporate process for integrating operator pipe spec provisions into MPSs and ITPs, for steel producers, steel suppliers and pipe manufacturers.

• Develop capability to provide real-time information, such as histograms of pipe properties, to monitor quality on an ongoing basis.

• Define key process check points that do not compromise proprietary aspects of production.

• Conduct Workshop on Best Practices for Pipe Manufacturer QMS.

• Evaluate enhancements to traceability, testing, retesting and verification of non-conformance practices

Status: Continuing.

• Work group reviewing practices to anticipate changes in API 5L.

• Coordinating with Work Group 4 to anticipate response to best practices.

• Evaluating enhancements to traceability, testing, retesting and verification of non-conformance practices – may involve use of technology.

• Best practices on quality management system.

• White paper on key elements of quality management system Group 5 – Evaluation of Enhancements to Pipe Manufacturer Specifications and Practices.

Best Practices were shared at INGAA Foundation Pipe Quality Summit in June 2009; with a

workshop on Procurement and Inspection Best Practices was held in June 2010.

• White Paper on Procurement and Inspection Best Practices is being drafted.

• Working with API and manufacturers to facilitate implementation and consistent application.

Groups 6/7 (Groups Combined For Working Purposes) – Understanding Steel Stress Strain Behavior and Pipe Expansion; Develop Methods to Understand Implications of Stress and Strain on Expansions and Implications to Each Threat in ASME B31.8S

Scope 6: Develop methods to understand stress strain behavior in high-strength, low-alloy steels and the expansion of pipe in mill and field hydrostatic tests.

Action Plan:

• Document applicability of finite element analyses to model formation of localized expansions.

• Define modeling basis to understand the onset of yielding and the extent of yielding that can occur.

• Approach ASTM to develop standardized method for flattened strap specimens.

• Provide reference information about magnitude of uncertainty in Mill Test Report (MTR) data.

• Evaluate enhancements to Pressure Volume plot data evaluated during field hydrotests to recognize significant yielding (ASME B31.8, Appendix N, consider German Standard).

• Develop common basis for calculating expansion and incorporate into API 1163 (Overarching ILI RP).

• Apply variability in MTR values into model to project onset of pipe yielding. Develop basis for differentiating low yield pipe.

• Evaluate value of additional R&D to develop parametric study to validate modeling.

Scope 7: Develop a basis for managing pipe with reduced strain capacity, especially for 0.8 design factor systems, and evaluate each threat and impact of expansions on integrity. Focus on defects that are a result of strain, mechanical damage, weather, and outside force. Address by grade as margin between Y and T deceases.

Action Plan:

• Define how much reduction in yield to tensile is allowable and how the Y/T relates to total strain.

• Evaluate current strain limits in B31.8, i.e. – 2% total strain and suitability as a threshold.

• Evaluate suitability of higher levels of strain with additional O&M provisions.

• Evaluate each threat and define impact.

• Demonstrate that each threat was evaluated below a threshold level.

• Above threshold, develop more conservative O&M practices.

• Consider interactive threats; especially those resulting from strain.

Status: Effectively Complete.

Work groups 6 and 7 were combined and work products integrated into a common decision tree. Original scope of tasks in Group 6 and 7 are effectively complete. PRCI will conduct a critical review of this work and prepare a Gap Analysis to identify any need for additional work.

Other results:

• Clarified the relationship between mill and field hydrostatic tests – “effective combined stress.”

• Developed a generalized stress-strain model for niobium/vanadium, low microalloy X-70 steels.

• Validated by burst tests from several operators.

• Model developed is slightly more conservative than that published by ASME.

• Working to define improvements standard for tensile testing.

• Developed white paper defining basis to evaluate/interpret deformation tool data based on manufacturing requirements, testing & performance – white paper routing for final comments.

Group 8 – Evaluate Implications of Expansions On Coatings

Scope: Evaluate the degree to which expansions compromise coating and ultimately lead to cracking and disbonding. Consider coating type (non-shielding vs. shielding, ARO), nature of expansion (localized or extended), among others.

Action Plan:

• Evaluate work conducted by PRCI and historical experience with bending tests.

• Evaluate data from expanded pipes.

• Develop test protocol and conduct tests. Initial work by manufacturers and coating applicators May require PRCI/PHMSA research.

• Establish guidance thresholds by coating type, and other factors to be determined.

Status: Effectively Complete.

• Developed white paper on research related to expansion and impacts on FBA coatings.

• Operators provided results from tensile tests on FBE-coated pipe.

• Developed a test matrix for additional tests on FBE-coated pipe.

• Tensile tests (1, 2, 3% to cracking).

• Production tests to confirm performance.

• Developed relationship between conventional bend tests and strain resulting in pipe.

• Preliminary work indicates that coatings are not the limiting factor.

• Crazing (stressing of coating) at 6% and cracking at 6-10%.

Working Groups – Pipeline Construction

Group 1- Best Practices in Implementing API 1104 Annex A

Scope: Enhance the utilization of API 1104 Appendix A by developing clear guidelines and understandable best practices for operators and contractors that provide a common, technically sound approach to the identification of essential variables, development of required data and application of the analytical methods.

Action Plan:

• Provide common, technically sound approach to the identification of essential variables.

• Development of required data.

• Application of the analytical methods.

Status: Work Group formed and work under way

Initial meetings have identified the importance of making the connection between what an engineer specifies as constraints in the stress analysis supporting the engineering critical analysis and actual work practices to be used during construction. An example is lowering of pipe into the ditch. The stress analysis must address the most conservative conditions to be used during construction. If for example, the maximum lift height will be 25 feet with four side booms at a specified separation, then the field practices must be maintained within those limits.

Key Deliverables:

• Survey operators’ experience in applying Appendix A – Q2-2010

• Identification of essential variables and boundaries – Q3-2010

• Draft Best Practices – Q4 2010

• Final Best Practices – Q1 2011

Group 2 – Resolution of API 5L and API 1104 NDE Issues

Scope: Identify the issues that have the potential to impact successful projects and develop a plan to resolve the issues.

Action Plan:

• Formalize membership in the API ad hoc Joint Liaison Work Group (JLWG).

• Define issues requiring resolution or enhancement from previous industry work products and forums.

• Present issues to JLWG for resolution during June 29th API meeting.

• Resolved issues from first meeting to be balloted for committee approval 4 QTR 2010 for incorporation into 5L Annex N via next addendum or errata slated for early 2011.

(Continue action on last item until completion of all documented issues.)

Status: Continuing

• API 5L and 1104 formed API/1104 JLWG composed of 6 – Manufacturers, 3 – Operators, 3 – Eng. Consulting, 2 – Construction Contractors, 1 – Vendor and 1 – Regulator, in late February 2010.

• Compilation of issues have been composed and currently under review for submittal during first meeting on June 29, 2010.

• First JLWG meeting scheduled for June 29, 2010 during the API & E&P Summer Standards Conference in Washington, DC.

Deliverables: Revised standards or clarifications to existing standards

Group 3 – Best Practices for Field Applied Coating

Scope: The proper application of field applied coatings is an essential element to the long-term integrity of a pipeline. Document common-sense best practices in the form of a white paper for use by Operators and Contractors.

Action Plan:

• Identify the numerous products and procedures currently used by industry.

• Develop a white paper of Best Practices.

• Evaluate other types of field-applied coatings (tape, wax, etc.).

Status: Work Group formed and work scope developed

Key Deliverables:

• Development of White Paper of Best Practices – Q4 2010

• Evaluate other types of field applied coating – 2011

Group 4 – Quality Management Systems (QMS) for Pipeline Construction

Scope: QMS has been employed in many different forms between Operators and Projects. This work group will provide best practices guidance for implementing QMS in a pipeline construction project.

Action Plan:

• Evaluate various practices being used or available.

• Develop a white paper outlining a framework for construction.

Status: Work group formed, first face-to-face meeting held in April.

Key Deliverables:

Develop a QMS white paper outlining a framework for construction – Q4 2010

Group 5 – Training Guidance (simplified “KISS” approach) for Construction Workers & Inspectors – Welding and Coating

Scope: Develop simple, but effective training guidance for construction management and workers to enable solid construction practices.

Action Plan:

• Analyze generally available specifications and procedures.

• Translate the detailed documents (“contract language”) into brief, simply stated requirements.

• Develop training guidance (KISS) document.

Status: Work Group formed and work scope under development

Key Deliverables:

• Key elements of effective training packages – Q2 2010

• Example of typical package for coating and welding – Q4 2010

• Workshop on implementing key elements Q1 2011

Group 6 – Welding of Field Segmented Induction Bends and Elbows for Pipeline Construction

Scope: Develop guidance for the use of field segmented induction bends and elbows for pipeline construction.

Action Plan:

• Develop guidance regarding specification and purchase of segmentable induction bends and elbows.

• Develop guidance for field construction practices including preparation of the bend or elbow, proper fit-up measurements and tolerances, welding including backwelding, and NDT.

Status: The JIP is formed and work has commenced

Key Deliverables:

The guidance described in Action Plans 1 and 2 will be completed and available by the end of 2010.

Summary

As the INGAA Foundation-led, best-practices efforts continue to foster reliability, integrity, safety, and confidence in the nation’s pipeline system, there are key issues and related action items remaining. But the importance of what has been achieved to date cannot be overstated. Industry recognized what needed to be done and set out to address the many issues in a timely and effective manner. The INGAA Foundation and its members have demonstrated and continue to demonstrate excellent stewardship in the process. The work being carried out today will make a difference for the future safety and integrity of America’s growing pipeline system.

Comments