September 2010 Vol. 237 No. 9

Features

Gas Management Solutions In Oil Production

As a supplier of advanced versatile solutions to oil field operators, Wärtsilä participates in the Global Gas Flaring Reduction Partnership (GGFR), a public-private partnership supporting the efforts of the petroleum industry and national governments to reduce the flaring of gas. In June, the company joined GGFR as an associated partner.

Oil production generally involves the processing of upstream fluids into a crude oil that meets certain specifications. This is typically done at a field processing facility and involves a number of operations in different processing systems within the facility. One primary function of this processing is “phase separation” to remove water, solids and gas from the produced fluid, thereby producing crude oil that meets the specifications and provides the main source of income for the operator.

The gases, i.e., the volatile hydrocarbons in oil, are the main technical focus of attention throughout the oil production process from the underground oil reservoir to the refinery gates. The amount of gas in the reservoir fluid usually dictates the oil field recovery methods, and the production planning stages of the hydrocarbons.

The relative amount of gas varies during the lifecycle of the field. The amount of gas in the reservoir fluid is usually expressed as the gas-oil ratio, GOR, and is mainly given in U.S. standard units: scf/bbl (standard cubic feet per barrel). Volatile components in the oil will also mean “shrinkage” during transport and decreased volume at the delivery point, despite being stabilized according to specifications. Vaporized hydrocarbons, i.e., fumes around the processing equipment and throughout the operations, are – besides being an environmental concern – the source of hazardous explosive conditions, and are, therefore, a key safety issue.

The major concern in oil production has been the removal of the separated gas from the process in the field processing facility. Traditionally the gas has been considered a waste and utilized only occasionally. Gas has not even been considered as an item in the production sharing agreements (PSA), because the profit and cost calculations of the oil production process have been based on oil, not on gas. Usually, the gas has simply been flared as an unwanted by-product of oil, due to various reasons that constrained its utilization.

During the last decade, global institutions and organizations, as well as the world’s energy industry, have awakened to the realization that huge amounts of energy are being wasted in flaring. At the same time, flaring also poses a severe threat to the environment.

The World Bank-led Global Gas Flaring Reduction partnership (GGFR) estimates that globally, around 150 Bcm of gas are flared or burned every year, causing some 400 million tons of carbon dioxide in annual emissions. That is equivalent to 30% of the European Union’s gas consumption.

Gas flaring not only harms the environment but also deprives developing countries of an energy source that is often cleaner and cheaper than others available. During the drilling for crude oil, gas usually comes to the surface as well and is often vented or flared instead of used, particularly in countries that lack effective regulations, gas markets and the necessary infrastructure to utilize the gas.

The U.S. Environmental Protection Agency estimates that more than 100 Bcm of methane is vented or lost through fugitive emissions in the oil and gas sector each year. As methane is a more potent greenhouse gas than carbon dioxide, this adds the equivalent of over 1 billion tons of carbon dioxide annually. Altogether, annual emissions from flaring and venting are equivalent to more than twice the potential yearly emission reductions from projects submitted under the Kyoto mechanisms.

The major flaring region in the world is Russia and the Caspian (about 60 Bcm); followed by the Middle East and North Africa (about 45 Bcm). Sub-Saharan Africa (about 35 Bcm) is the third-biggest flaring region, followed by Latin America with some 12 Bcm of gas flared annually.

The magnitude and volumes of flared and vented gases are globally monitored, including by satellites, but the exact figures are a matter of discussion. However, the general understanding is that the GGFR figures are conservative.

Associated Gas

Natural gas used by consumers is composed almost entirely of methane, and termed “pipeline gas” or “utility gas.” It is produced in gas fields, and usually processed to fulfill pipeline quality standards.

The gas in the wellhead fluid, although still composed primarily of methane, is by no means as pure. Natural gas that comes from oil wells is typically termed “associated gas.” This gas can be separate from the oil in the formation (free gas), or dissolved in the crude oil (dissolved gas). Typically, the biggest part of the associated gases is methane, but nevertheless, in most cases the methane share is below 50%. The associated gas (AG) also contains heavier (volatile) hydrocarbons; mainly ethane, propane, butane and pentanes. These heavier hydrocarbons can be condensed and have a higher heat-value, thus AG is in many cases called “wet” or “hot” gas.

In addition, AG may contain water vapor, hydrogen sulphide (H2S), carbon dioxide, helium, nitrogen, and other compounds. Such impurities cannot be handled and transported easily and, moreover, they would make the gas unfit for commercial consumption.

GGFR is challenging the industry to develop and find methods and technologies to enhance the reduction of flaring, but the group is not setting standards or priorities for solutions. It is undertaking a “partnership” role in supporting the efforts and proceedings of the participating countries and the industry, with the focus being on:

- improving the legal and regulatory framework for investments in flaring reductions;

- improving international market access for gas;

- providing technical assistance to develop domestic markets for flared gas;

- disseminating information, including international “best practices;” and

- promoting local, small-scale use of gas.

The target is to make de-flaring into an environmentally sound, energy-efficient and profitable concept.

Several oil-producing countries have already included de-flaring sanctions into their production sharing agreements with operators. Also, oil companies such as Shell and Chevron, have committed to de-flaring requirements in their new oil production projects. World Bank has issued a new GGFR charter offering opportunities for systems and services suppliers to join the initiative as associated members.

Utilizing Associated Gas

Technically, there are several options for handling and utilizing associated gas (Figure 1): 1) to provide power and heat for the field facility; 2) to provide power and heat for the adjacent premises, and for the power and heat grids; 3) to re-inject gas to maintain the reservoir pressure, or for the enhanced oil recovery (EOR) process; 4) to re-inject gas for later gas production; 5) to process the gas for pipeline gas or LNG (liquefied natural gas) production; and 6) to process the gas/NGL (natural gas liquids) for LPG (liquefied petroleum gas) and the petrochemical industry feedstock.

Figure 1: Production of oil and associated gas (Source: Jumppanen, Finnish Barents Groupp).

Detailed and comprehensive lifecycle plans for hydrocarbon production will be made for each oil field in order to specify the facility equipment and resources for each production stage, defining mainly:

1) Upstream flow development in the production stages, e.g. production wells hooking-up program;

2) Water cut development in the production stages;

3) Oil production in the production stages, starting from “early oil” through one or more “oil production plateaus” (the continuous constant production of each stage) into field depletion;

4) Gas-oil ratio (GOR) through the production stages;

5) Total cumulative oil recovery target from the reservoir;

6) Power demand in the production stages will be an outcome of these plans. The basic concept is electrical power generation for the field facility processes from the upstream to downstream oil shipping pumps. The power generation can be combined with heat recovery (combined heat and power – CHP), if needed.

The oil production plateaus will be the core of the field economy, usually as “BOPD,” barrels of oil-per-day. The revenue to the operator is based on these BOPD, and the production costs are also commonly calculated based on these BOPD.

Naturally, there will be fixed costs, and the major reductions will come from the host country in taxes, royalties etc. The utilization of AG will be further evaluated to determine its affect on the cost-per-barrel.

Each oil field is unique, notably in terms of the production cost structure in general, and the energy consumption in particular. Energy may constitute a significant cost factor, if procured from the electricity grid. Some of the produced crude oil can be used as fuel for the field facility power plant, in which case the cost can be valued as “lost revenue.” The most economical means is to use waste, i.e. the associated gas if available, as power plant fuel.

Gas-oil ratio (GOR) describes the amount of gas in oil as scf/bbl (also as Nm³/ton). The oil reservoirs are in many cases classified based on GOR, and the term is also used to describe the hydrocarbon liquids in general (Figure 2).

Figure 2: Typical reservoir compositions (Source: Penick, Oil & Gas Journal).

GOR varies throughout the field’s lifecycle, but in most cases there is enough associated gas to provide field power production. The GOR value is often a matter of discussion within the industry and in particular projects, for example initial GOR vs. produced GOR. The GOR-value up to 2,000 indicates light crude oils, and represents the highest normal values of “low-shrinkage” crude oils. However, for example in Russia, GOR on average is about 600 scf/bbl, and in heavy crude oil fields the initial GOR may range from 100-200 scf/bbl, as in South America. It is possible that the GOR is even nil, in which case the crude oil is called “dead oil.” At the other extreme, a GOR value of over 4,000 means condensate products and further on, ending up as gas with no liquids.

Power Needs

In general, oil production is a very energy intensive operation. Electricity demand for oil production has been (e.g., in Russia) on average about 15 kWh/bbl. However, that figure varies within the range from 5-50 kWh/bbl, depending on the “watercut,” the water content in the upstream fluid in particular, and also on the gas re-injection.

The heating value of AG is higher than the lower heating value (LHV) of the pipeline gas, varying in the range of 40 to 50 MJ/Nm³. The average energy need of 15 kWh/bbl could thus be covered with an AG-fueled Wärtsilä power plant, when the GOR-range is about 90–120 scf/bbl.

The excess power, as well as heat, can be distributed to communities adjacent to the field, or to the power grid, if there is feasible access. This provides a possible secondary revenue to the operator, or an opportunity to support the communities of the host country. In some cases this utility service is an obligation to the operator, and the power plant shall therefore be specified accordingly.

The other approach is to specify the field power plant according to the power requirements of the oil production process, and to proceed with the excess gas utilization separately (Figure 1). The first step is to gather the excess AG and store it for future use. In the early stages, oil production begins with the basic gas-oil separation process, “GOSP.” Thus, the AG production stream will start from the very beginning.

Excess AG can be re-injected immediately into the reservoir, depending on the reservoir structure, to maintain the well pressure. For future use, temporary underground gas storages can be drilled. The further processing of that stored AG can be done later, providing naturally that the necessary processing additions have been installed. The future AG processing will then depend on the development of the infrastructure in the adjacent areas, access to the pipeline gas grid, the LPG market and distribution, and deliveries to (future) petrochemical plants, and so on. These investment additions for the future businesses will pose specific challenges to the field economy.

In the economic evaluation of the development of a particular oil field, the reduction of CO2 must also be considered, as the cost, or savings in carbon credits, may create a significant element in the field’s profitability.

Wärtsilä Technology Solutions

The specific solution for power production in oil fields is based on Wärtsilä gas-diesel (GD) technology, for AG-fueled applications in particular.

The GD technology was introduced in 1987 with the Wärtsilä 32GD, the first gas engine in the Wärtsilä portfolio. GD technology makes it possible to run the engine on either gas or oil liquids; associated gases of almost any quality and liquid oils from diesel oil to heavy fuel oils, including even crude oils.

GD engines use the diesel combustion cycle in both gas and liquid fuel operation, which gives them the characteristics and rating of a diesel engine at all site conditions. In the gas mode, 4% of the fuel is needed as liquid pilot fuel to initiate combustion. GD technology also provides the efficiency and minimal de-rating of a modern diesel engine.

An enhanced innovation in the use of GD technology, called fuel sharing, was introduced in 2002 for plant operation where the gas supply is not constant, or where the quality of the gas varies.

The fuel-sharing system allows the engine to run on gas and liquid fuel in different proportions, in order to optimize plant operation according to the availability of the fuels. If, for example, only 30% of the rated output can be achieved with the available gas, the engine makes up the balance of 70% of the output with fuel oil. The operator can freely change the set point of the fuel share, and the control system will ensure that the actual operating point is within the specified operating windows.

An 11-MW power plant at a field facility in Ecuador has been in operation since 2003 using two Wärtsilä 16V32GD units. The plant has been fueled by the associated gas and crude oil from the processing facility and it utilizes the fuel-sharing system. The fuel sharing is becoming very important now that the AG production is decreasing, and the gas flow has been very limited and highly variable (Figure 4). Thus, the plant has continued full output operation with a higher share of the liquid fuel, the crude oil.

Figure 3: Varying associated gas composition in Ecuador (Source: Jacob Klimstra, Wärtsilä).

In another oil field facility in the Amazonas, Wärtsilä installed a crude oil-fueled power plant in 2002. The operator has ordered Wärtsilä to convert the four Wärtsilä 18V32 units into gas diesel engines, fueled with associated gas from the process and crude oil as the pilot fuel oil. The goal of the operator is to reduce gas flaring and to enhance plant economy.

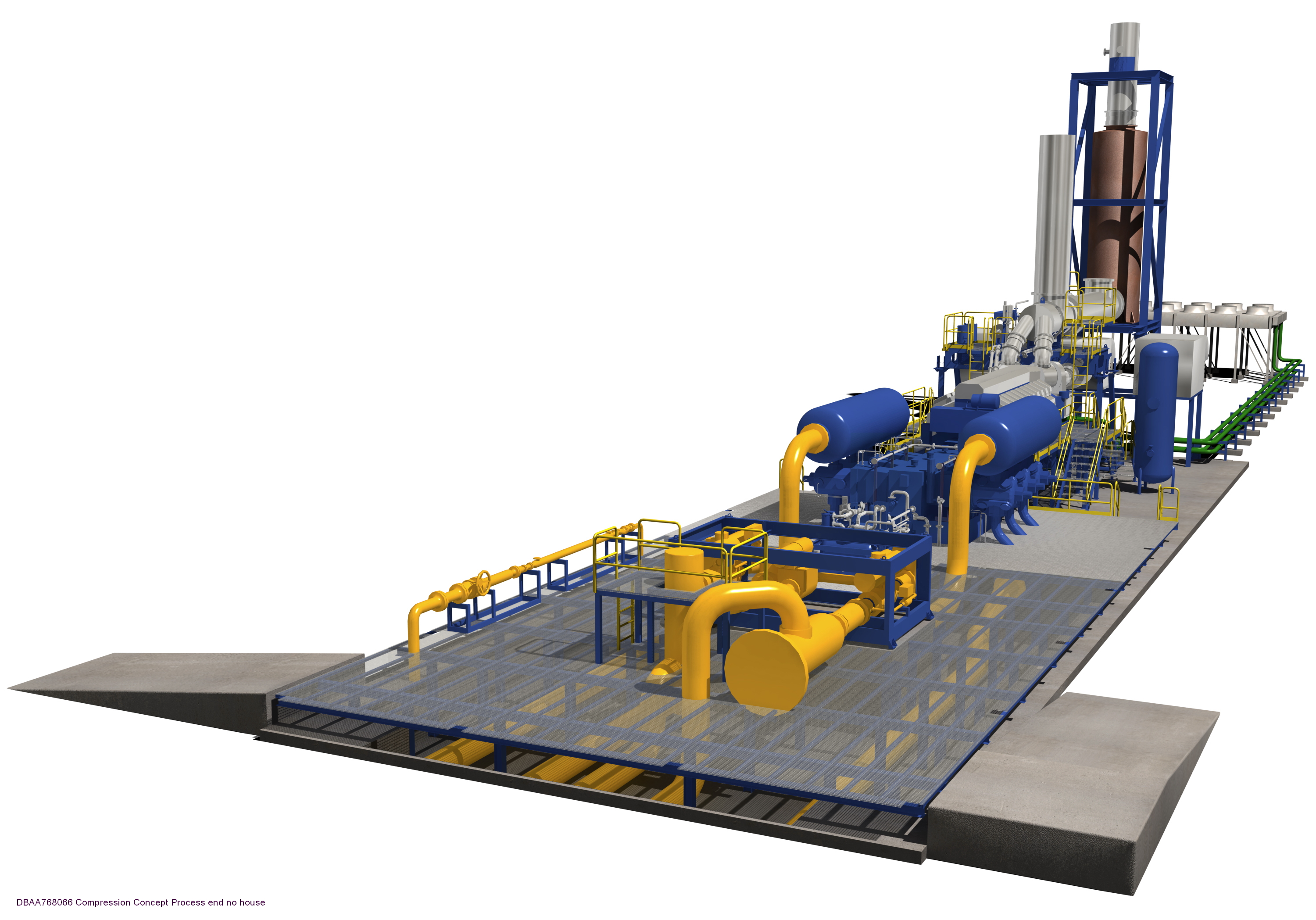

Gas diesel engines can be also utilized to drive gas compressors for the re-injection of the excess AG into the well structure to maintain the pressure, to enhance oil recovery, or even to be stored for later gas production, as discussed above.

The economics of the development and lifecycle of a particular oil field are complex and difficult to model with a conventional feasibility study. There are many parameters that influence the model of the various options, and these parameters may change dramatically during the life of the field. For example, the levels of investments needed for the various options are different. The ultimate consideration for the operator is the cost of producing a barrel of oil, but clearly what works for one site may not work for another.

A study of the gas management of oil production was conducted for a 12-year operation cycle, with the oil production plateau being 50,000 bpd. The associated gas utilization consists of fueling the field facility power plant, and the re-injection compressing of the excess gas. The reinjection compressors were also powered with the AG fueled GD engines. The total installed power of the GD engines was 36 MW, but the utilization varied according to the gas production (Figure 5).

Figure 4: Production of associated gas and carbon credit profiles.

The total gas production during that 12-year cycle is 6,400 mln.nm³ and the peaking GOR is about 1,400 scf/bbl. The total fuel gas for the power plant and the re-injection compressors is 700 mln.nm³, corresponding to about 11% of the produced gas during the 12-year cycle.

In addition to the stored gas, savings in carbon credits will be about 17 million tons, as opposed to flaring that stored gas throughout the 12-year cycle.

As a supplier of advanced versatile solutions to oil field operators, Wärtsilä is participating in the Global Gas Flaring Reduction partnership as an associated partner to promote the reduction in flaring (Figure 5).

Author

Pekka A.E. Laine graduated from Helsinki University of Technology in 1973 with a M.Sc.Eng. degree. He joined Wärtsilä in 1985 and since 1994 has concentrated on tasks in the Power Plants unit, focusing on “Powering the Petroleum Production Process.” His responsibilities include business and project development for oil production, onshore, world-wide; marketing and sales support for oil production and pipeline projects; project implementation support; and crude oil applications. 358 10 709 0000.

Comments